Patents

Literature

68results about "Meat deboning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deboning system of meat

InactiveUS7198564B2Low costMaximum efficiencyMeat holding apparatusPoultry processingShoulder BladesEngineering

Owner:MAYEKAWA MFG CO LTD

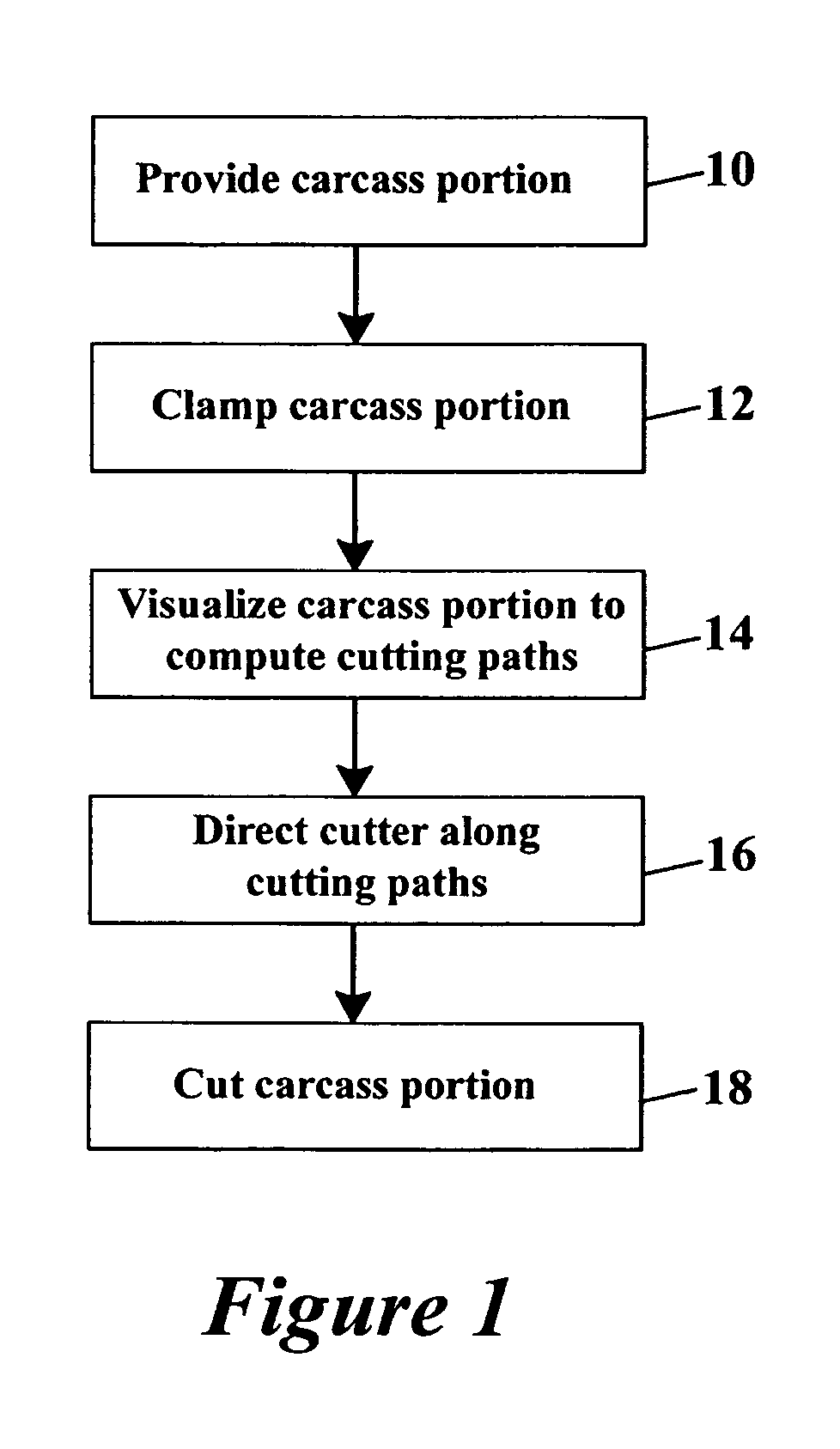

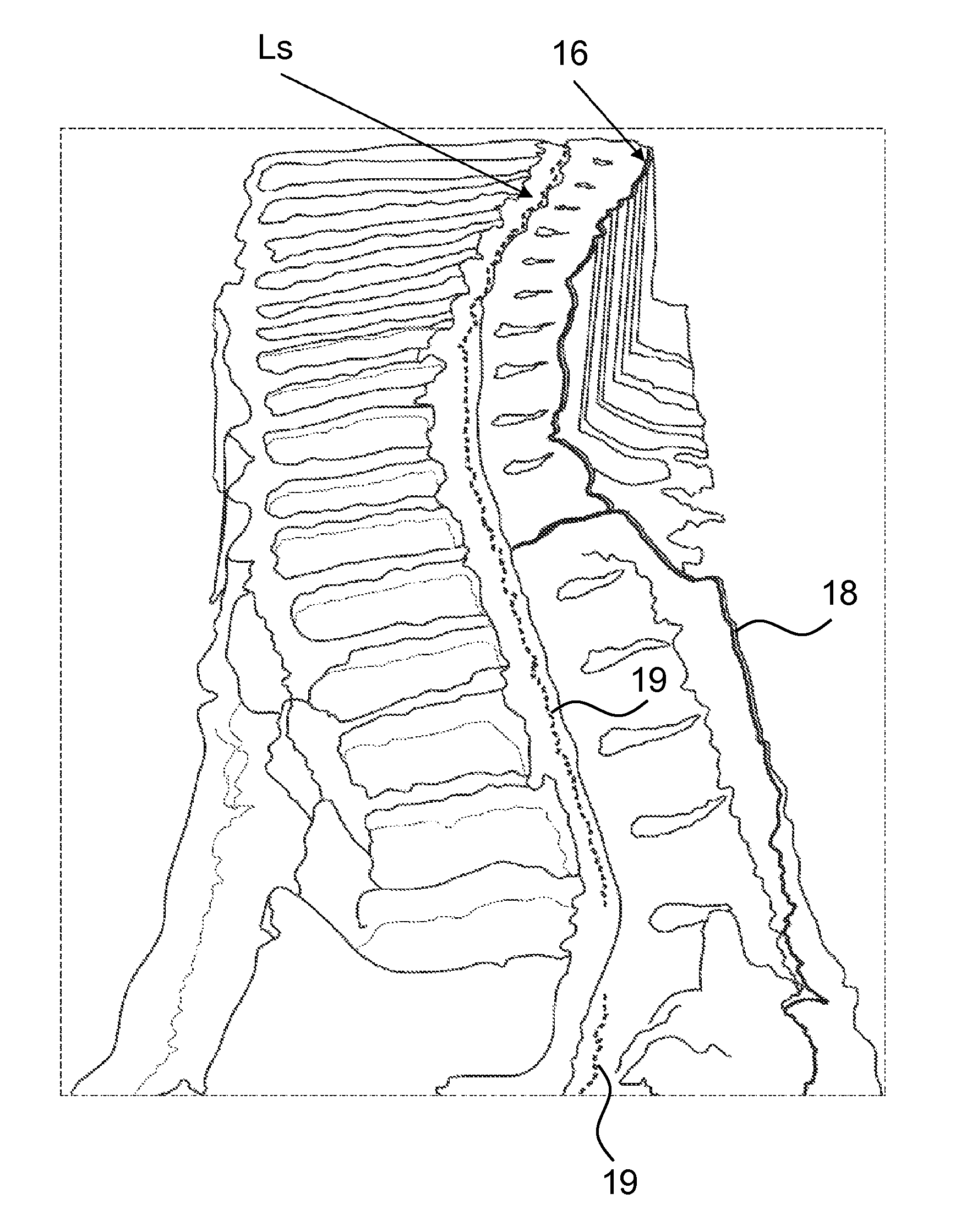

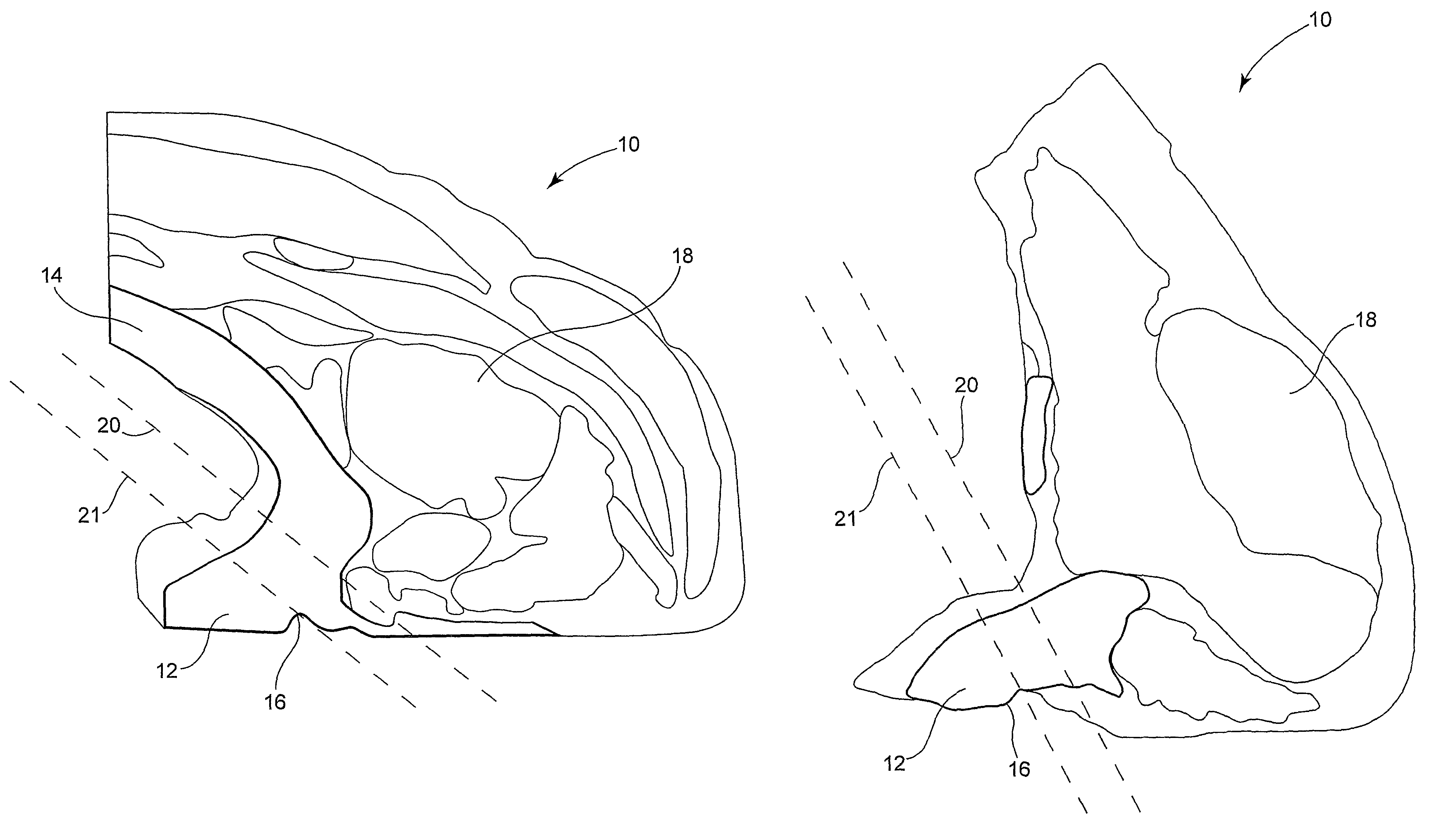

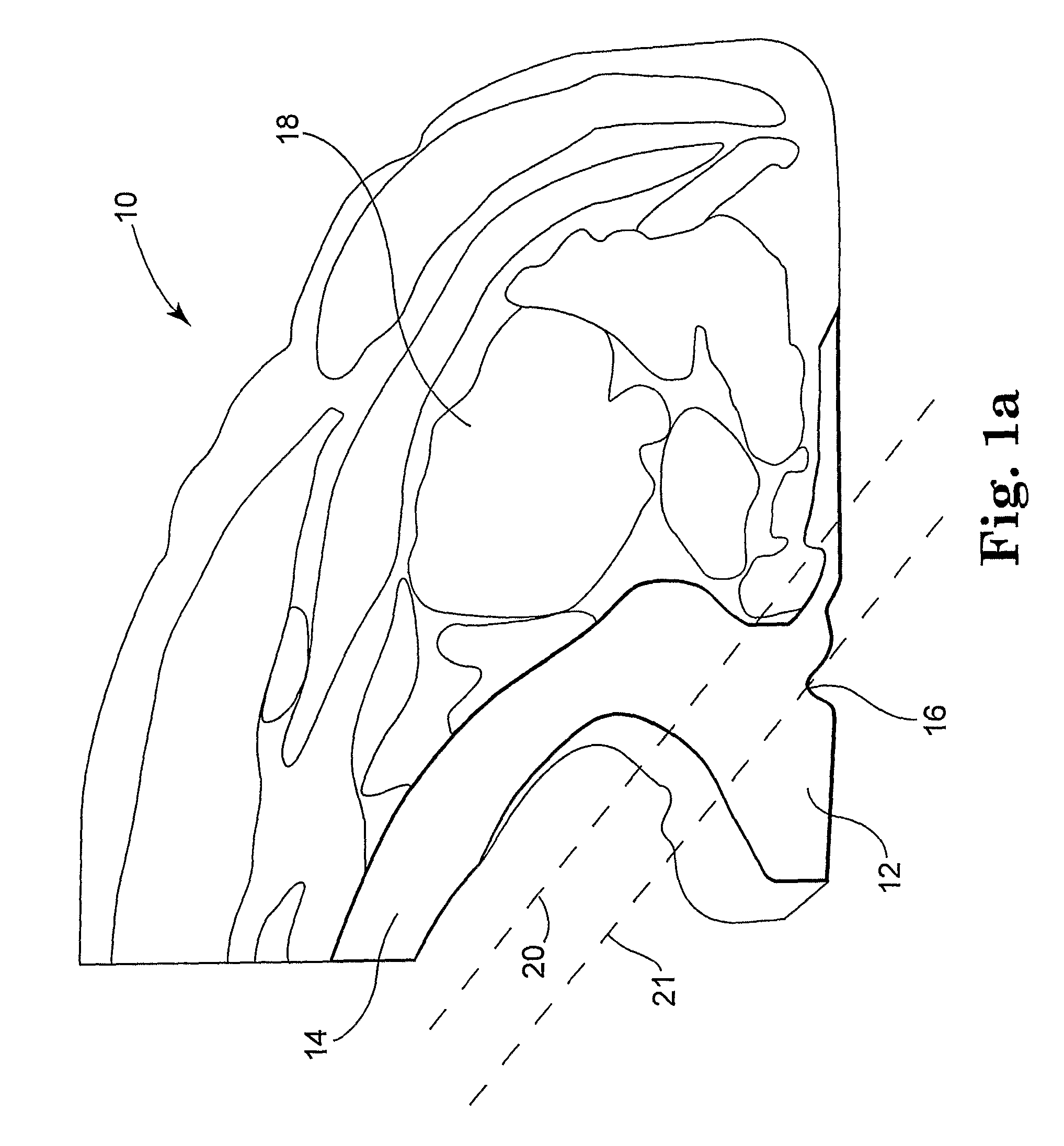

Spinal column removing method and spinal column removing apparatus

ActiveUS7404759B2High yieldEfficient removalMeat processing plantsPoultry processingSpinal columnBiomedical engineering

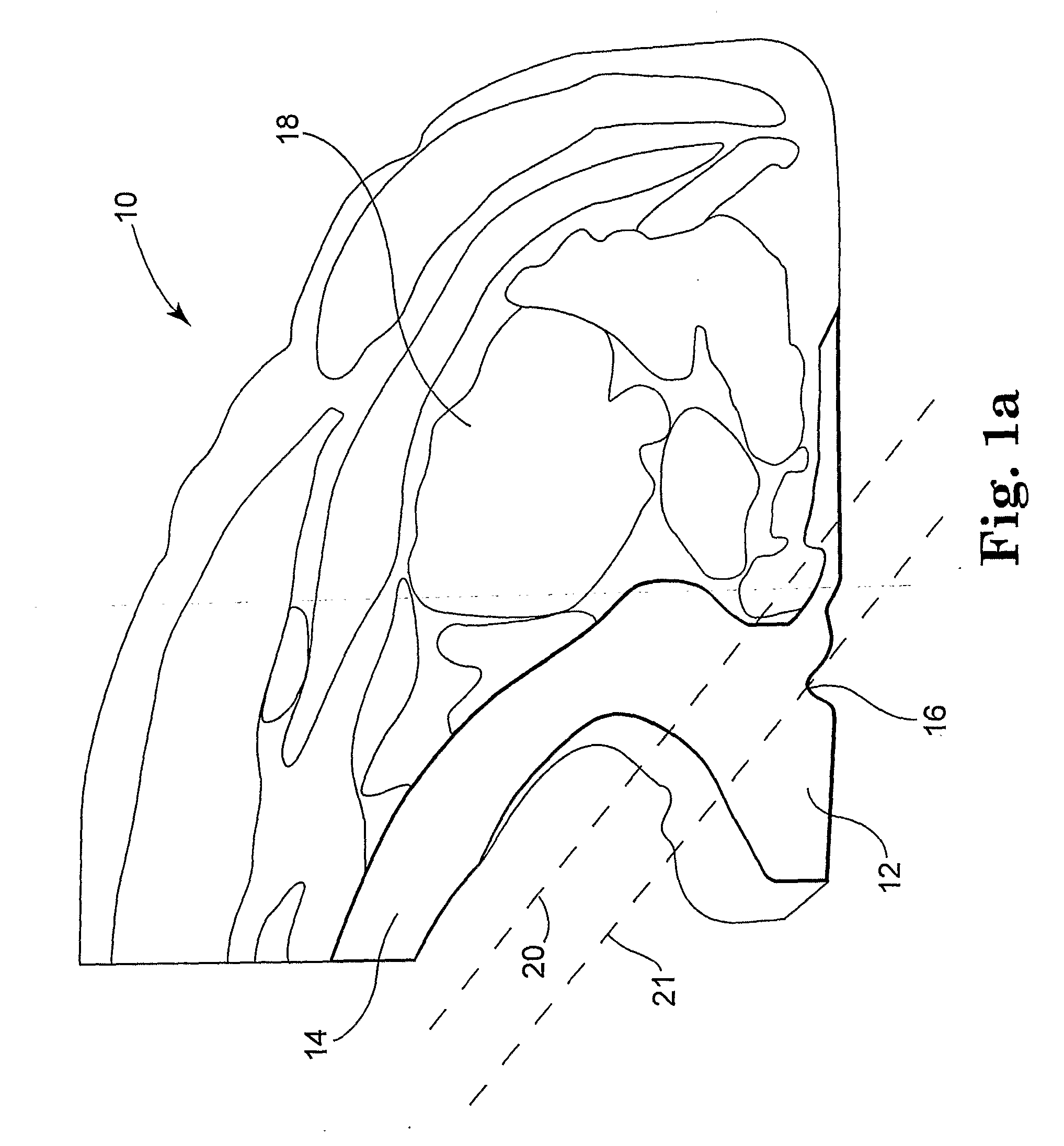

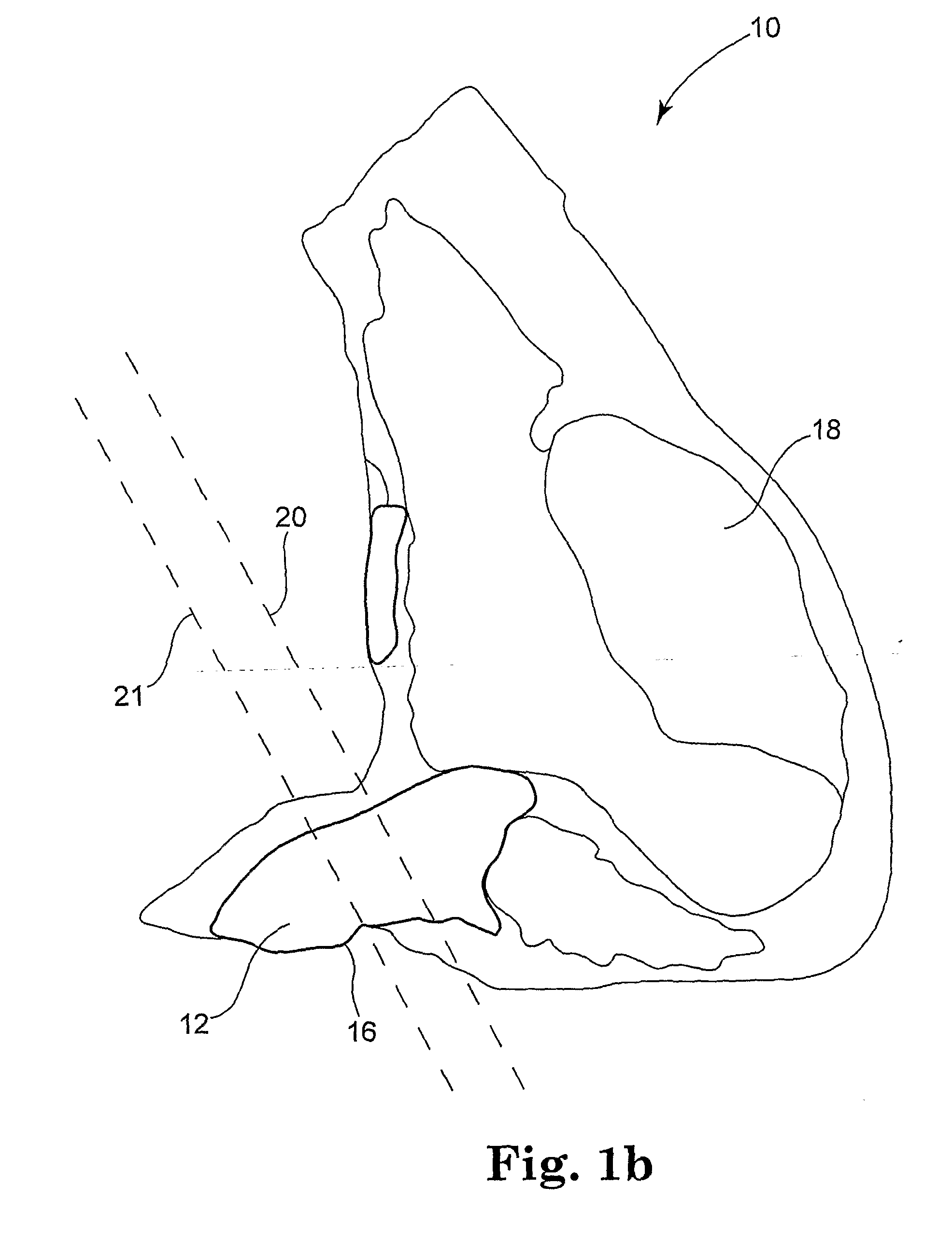

The method for removing a spinal column from a block of meat which includes detecting the position and shape of the spinal column in the block of meat that includes at least a part of the spinal column and cutting the block of meat in the vicinity of the spinal column in a V-letter form from two directions by three-dimensionally controlling the position of a cutter based on data concerning the detected position and shape of the spinal column.

Owner:MEAT TECH R & D PARTNERS

Meat cutting system

Owner:CARGILL INC

Decoring saw

InactiveUS6120367ASpeed up removalQuantity minimizationMeat holding apparatusBone cleaning devicesEngineeringKnife blades

Owner:TYSON FRESH MEATS

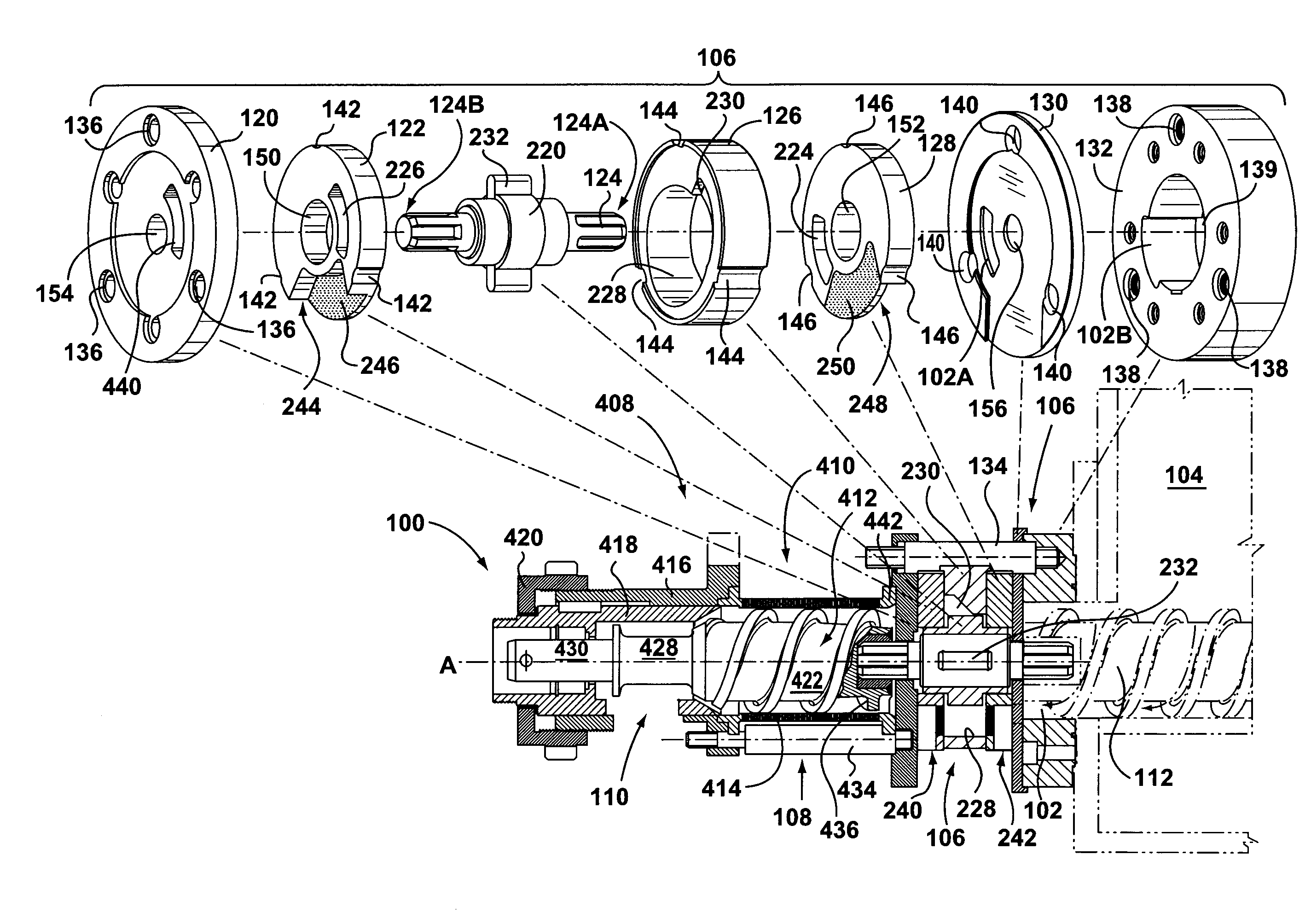

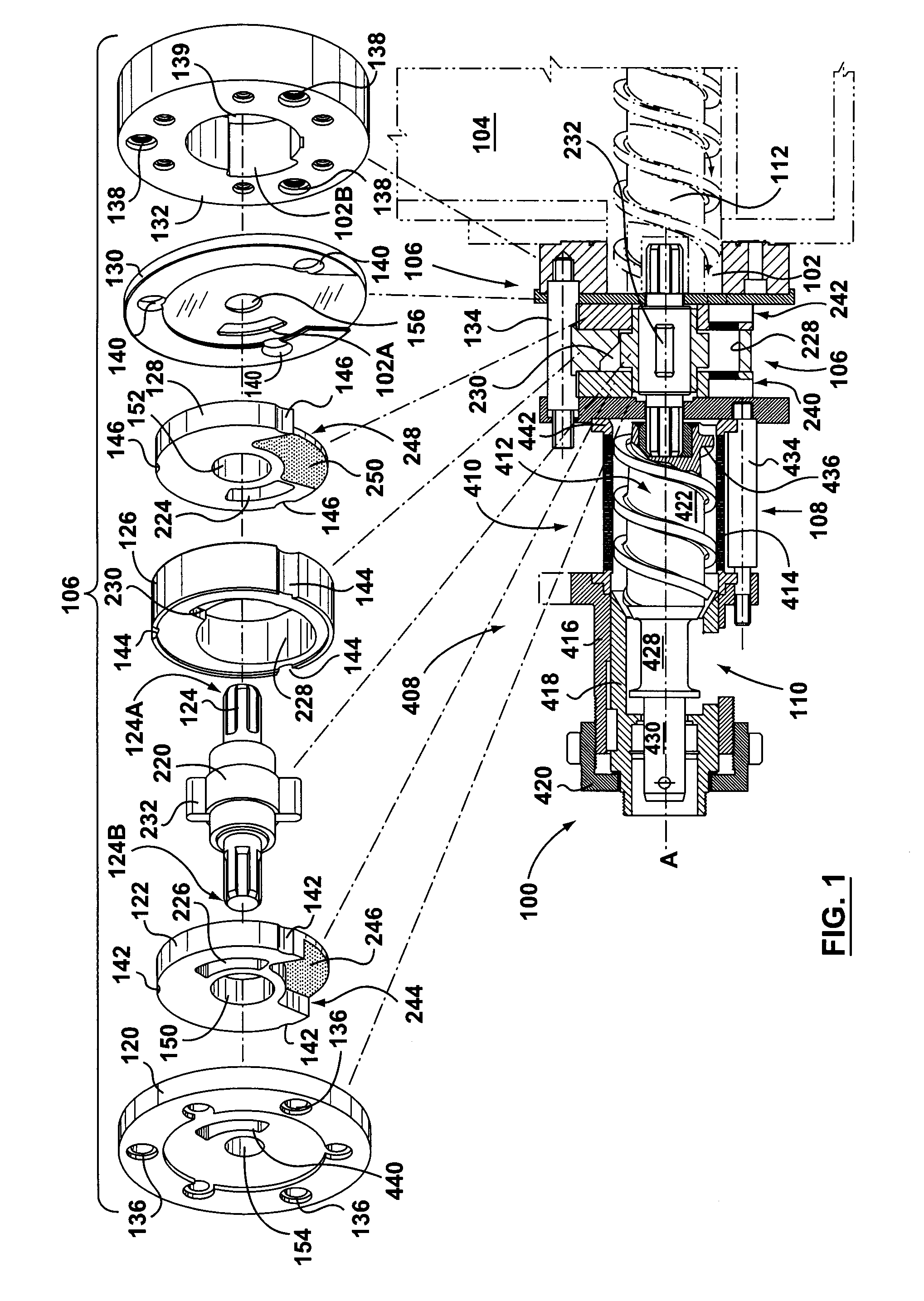

Method and apparatus for separating meat from bone

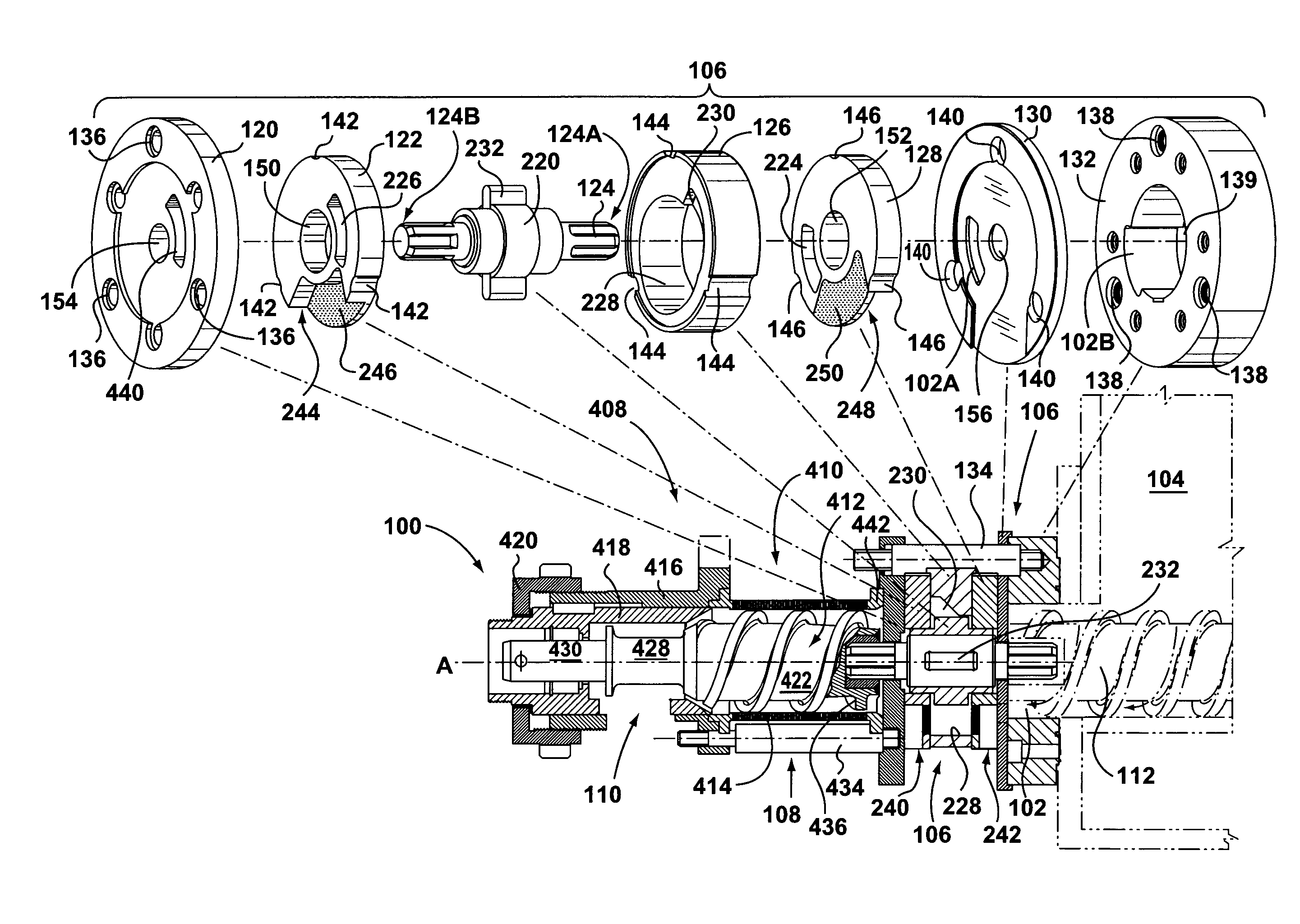

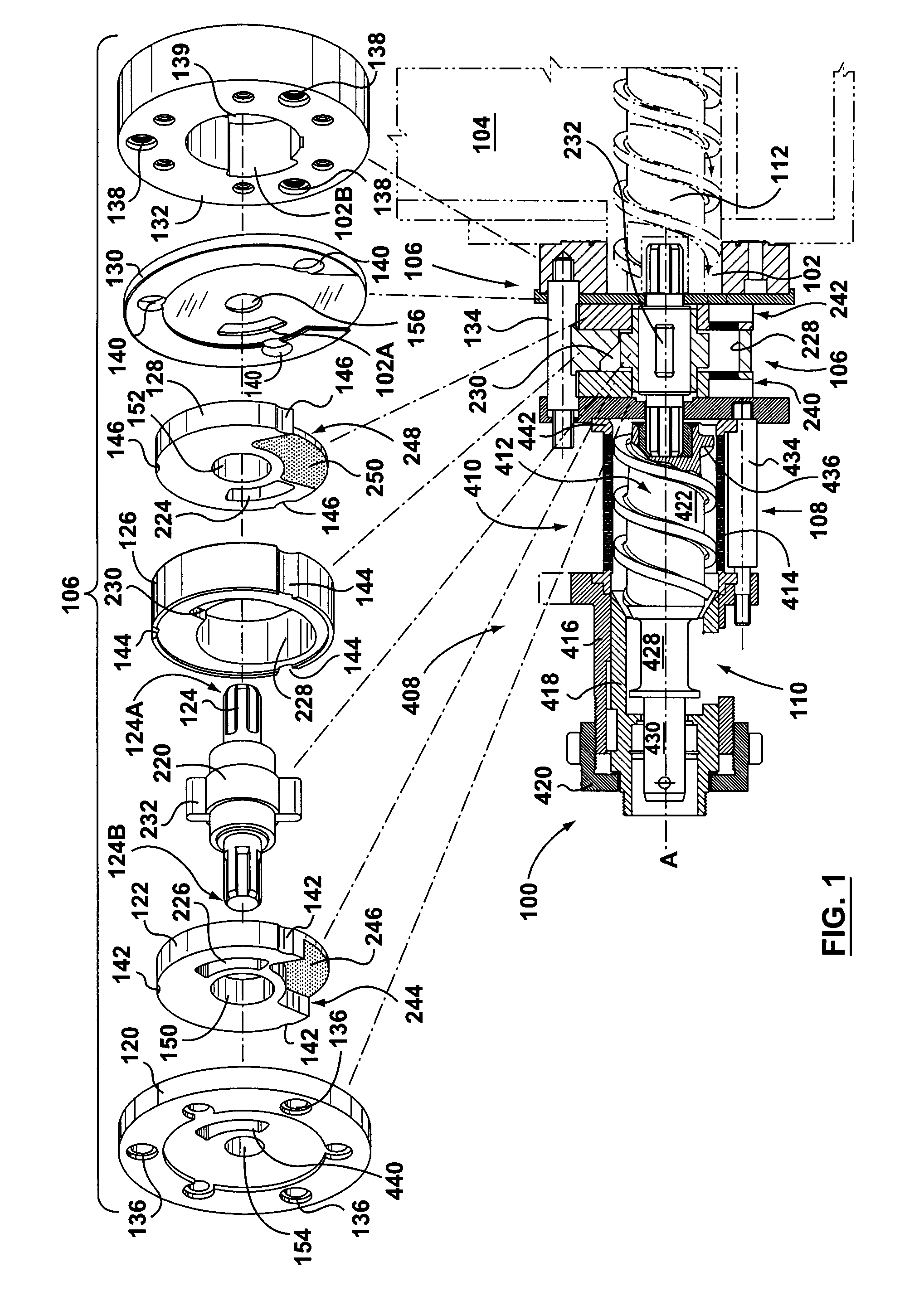

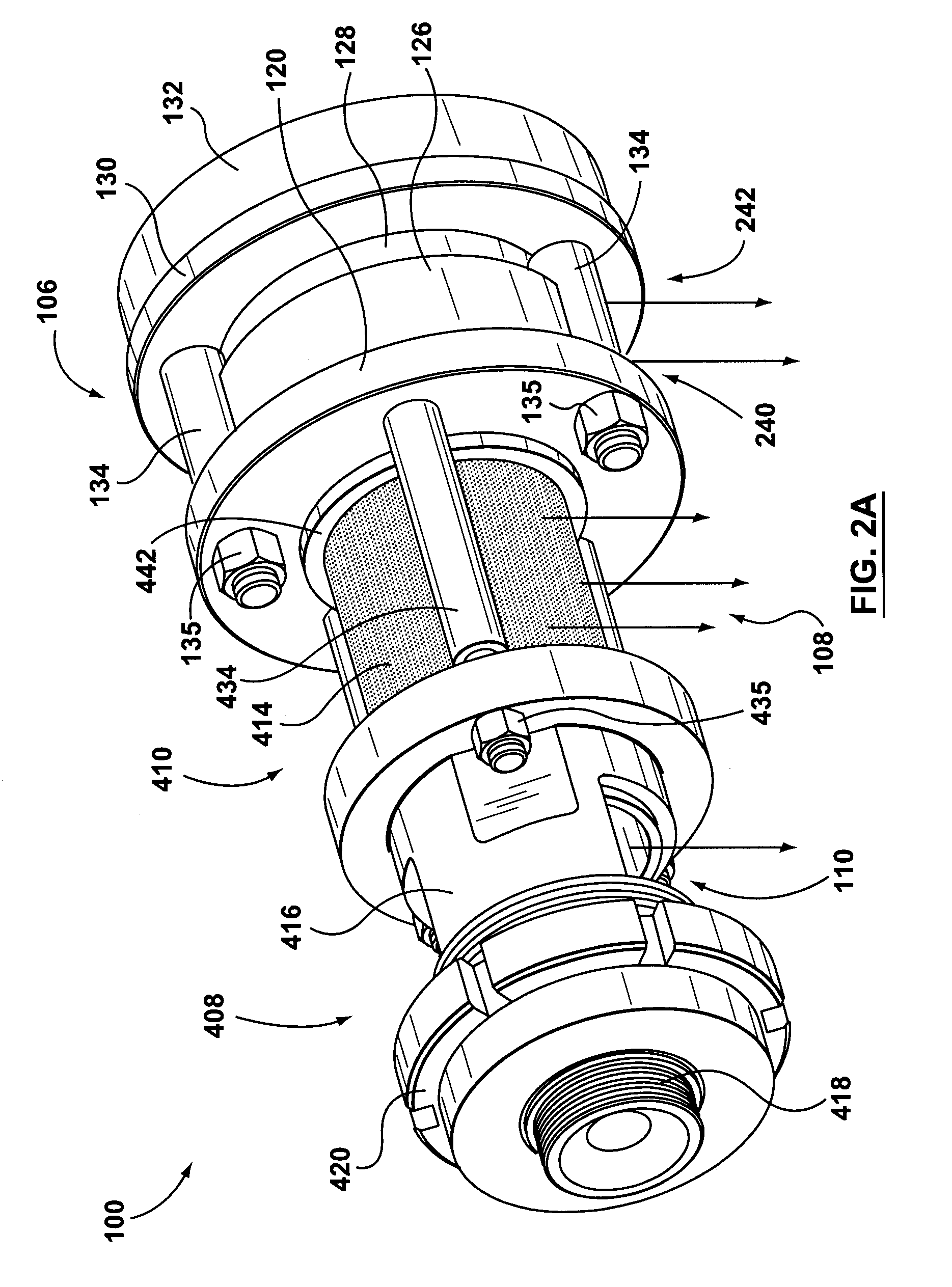

A separator apparatus that separates meat from bone in two distinct separation stages includes a rotary cam pump in series with a deboning screw assembly. In the first separation stage, substantially bone-free meat is separated from bone as the meat-bone mixture passes through the rotary cam pump, and expelled from the separator apparatus. The rotary cam pump then drives the remaining meat bone mixture into the deboning screw assembly, where a second separation stage occurs in which additional substantially bone-free meat is separated from bone as the meat-bone mixture passes through the deboning screw assembly, and is also expelled from the separator apparatus. The remaining bone residue is expelled from a bone residue outlet on the separator apparatus. The meat separated during the first stage can have a different coarseness than that separated during the second stage, and each can be expelled and collected at a different location.

Owner:POSS DESIGN LIMITED

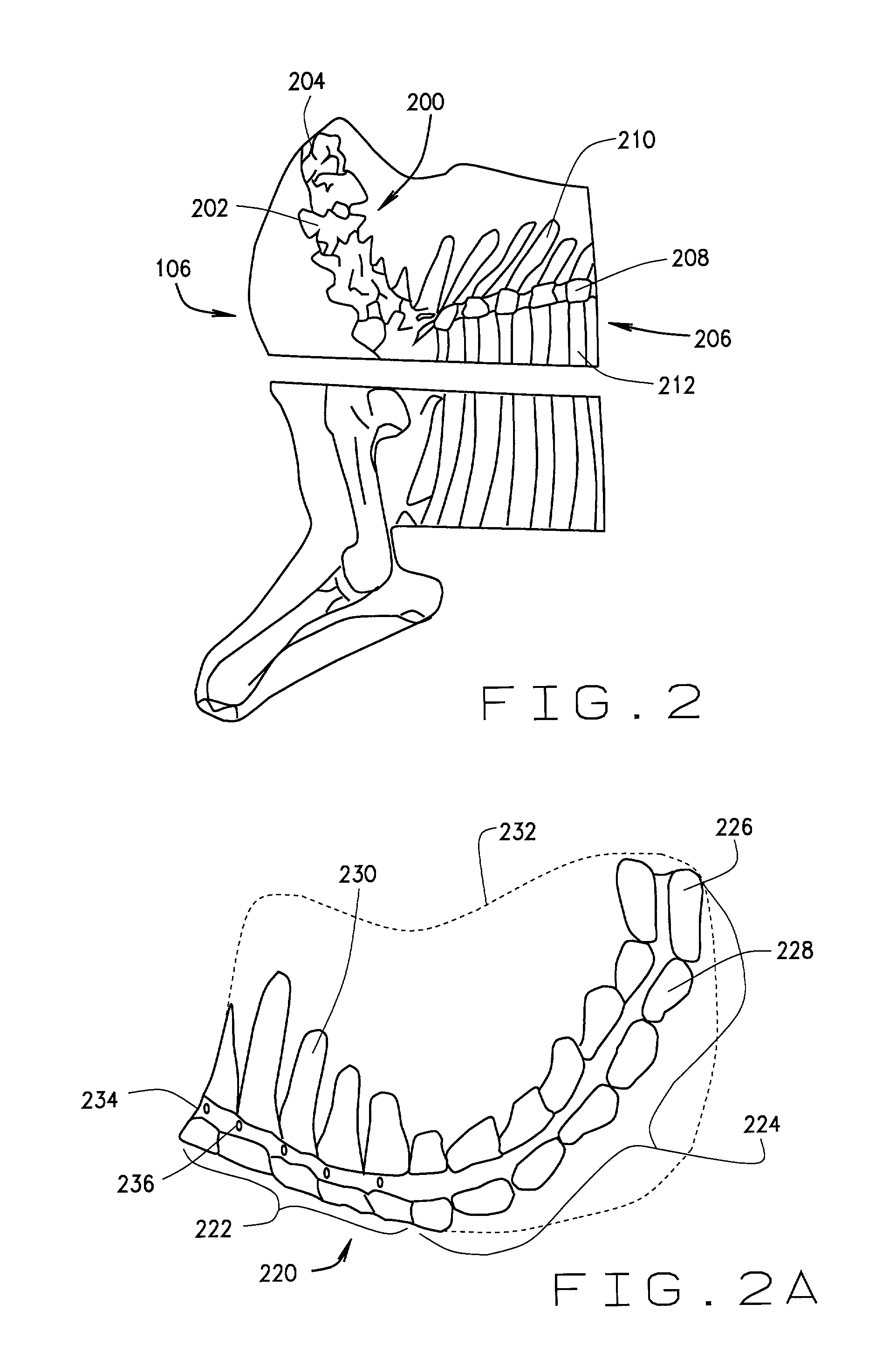

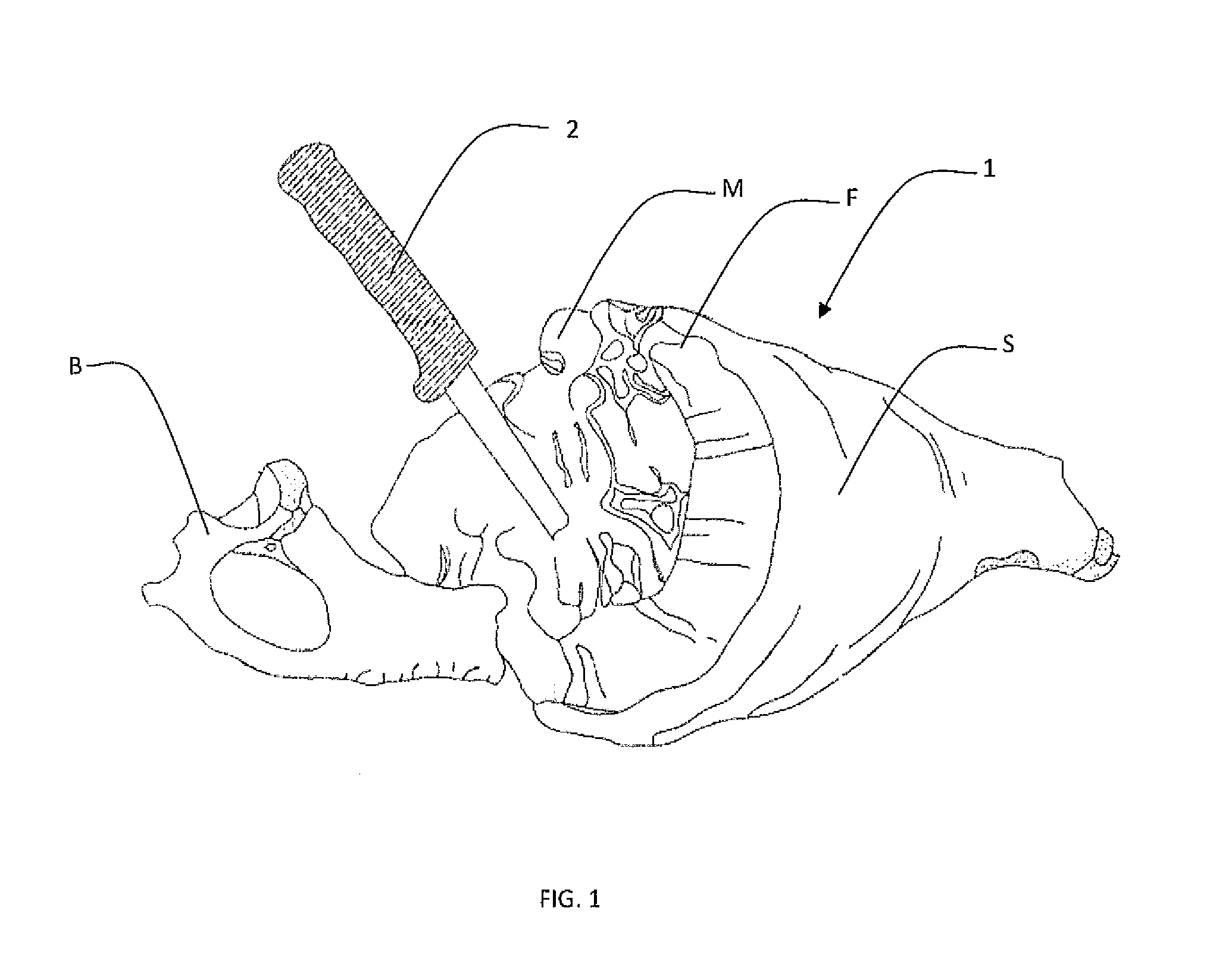

Apparatus and method for removing bones from a disassembled animal carcass

InactiveUS20030008608A1Eliminate difficultiesMinimal damageMeat processing plantsPoultry processingRotary stageChisel

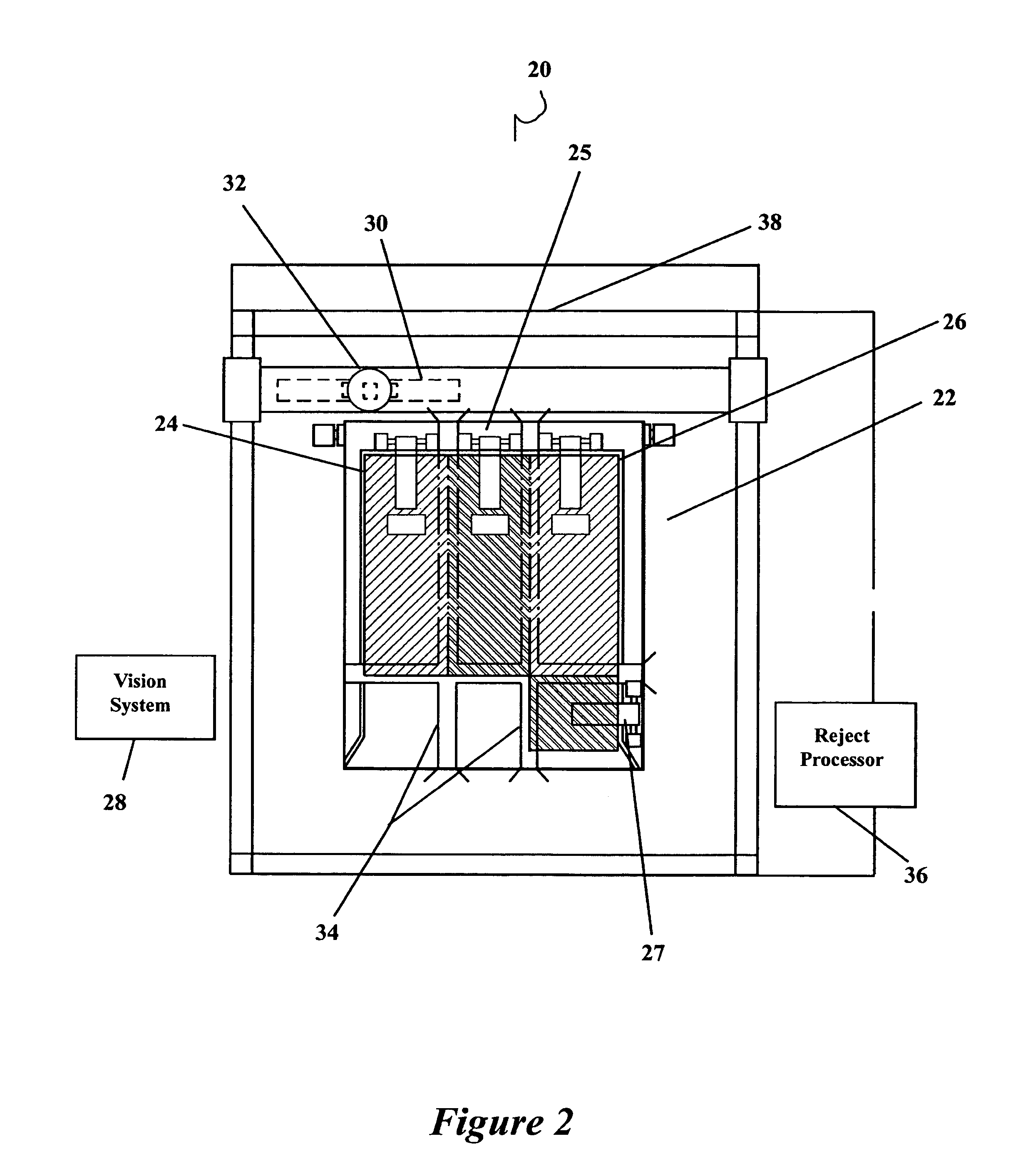

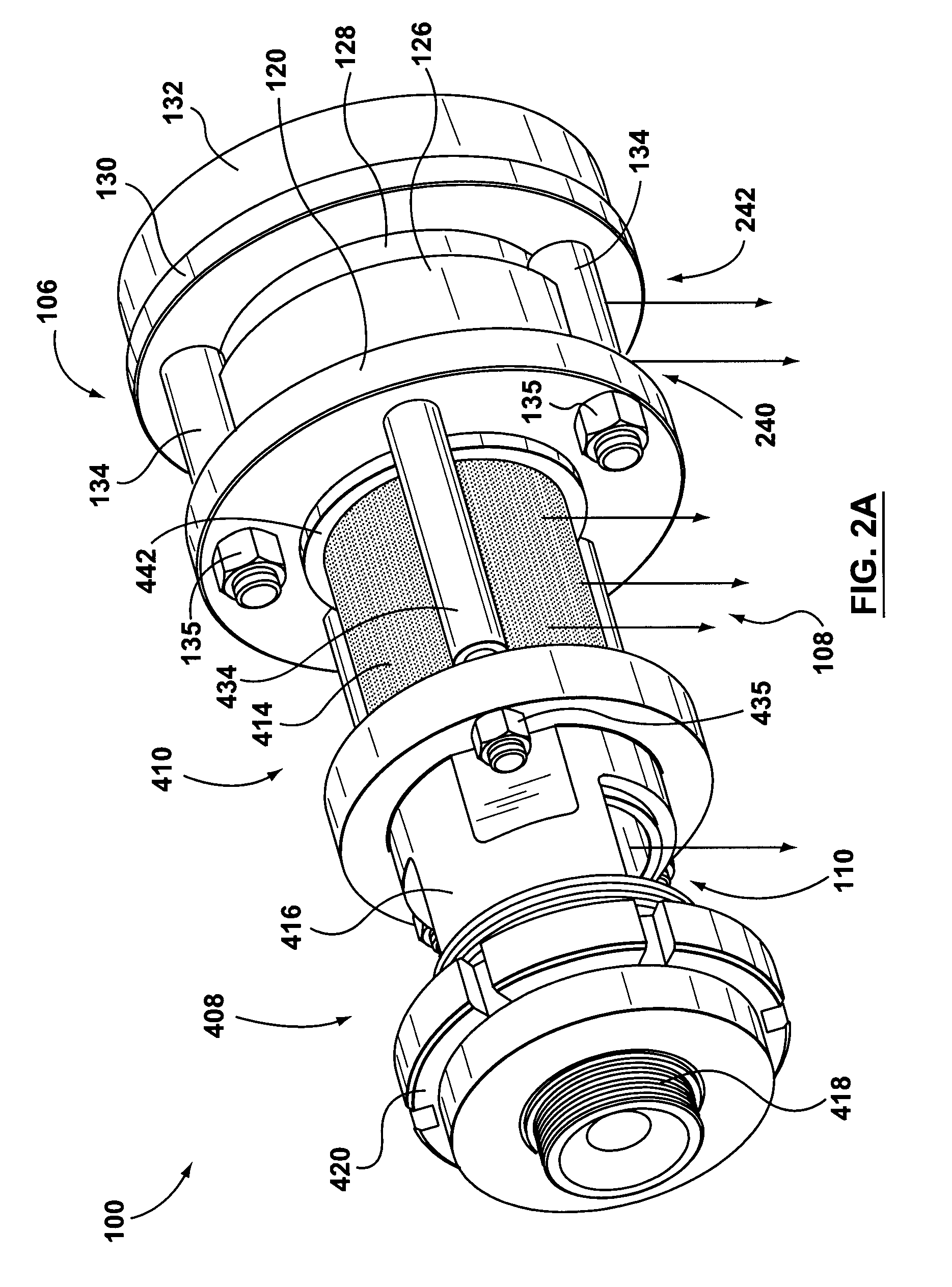

An apparatus and method for removing bones from a sub-primal cut meat portion, and more particularly, an apparatus and method for removing bones from a chuck blade sub-primal cut meat portion where said apparatus includes a carousel-type conveyor system arrangement having at least one mounting station and at least one meat cutting station. The carousel-type conveyor has a mounting fixture that is adapted to hold and manipulate and orient the meat cut such that bone removal can be performed effectively. The carousel-type conveyor in one embodiment is a rotation table which transitions the mounting fixture with the sub-primal cut mounted thereon to a position adjacent a cutting station. Each cutting station includes at least one reciprocating chisel blade assembly that is utilized to sever the meat from the bone by repetitively plunging and retracting a chisel blade into and from the meat and bone interface with a reciprocating stabbing action thereby severing the meat from the bone. The maneuvering and cutting pattern of the chisel blade assembly is controlled by a controller which can be a PLC or a computer or any other appropriate computing device.

Owner:TYSON FRESH MEATS

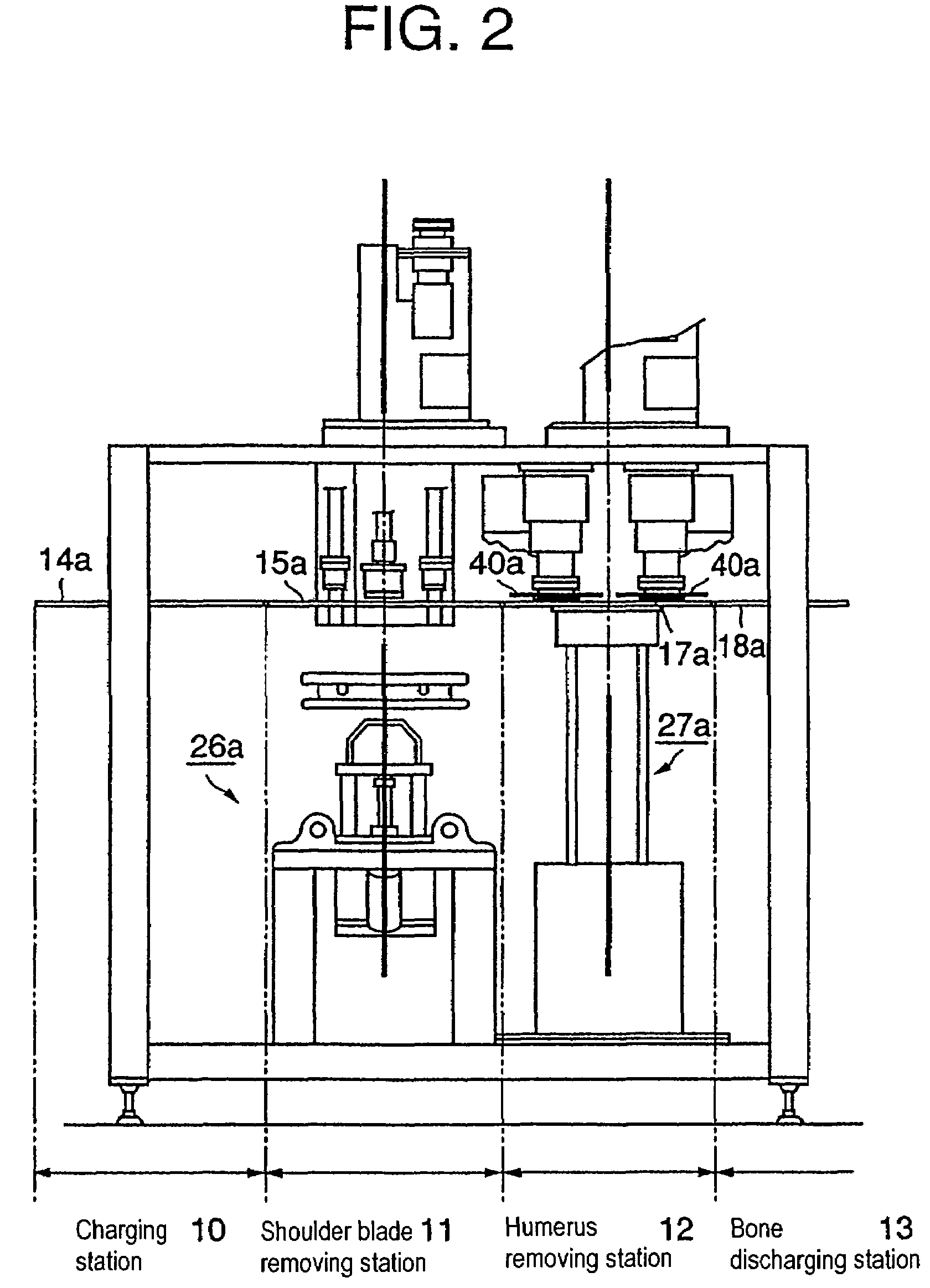

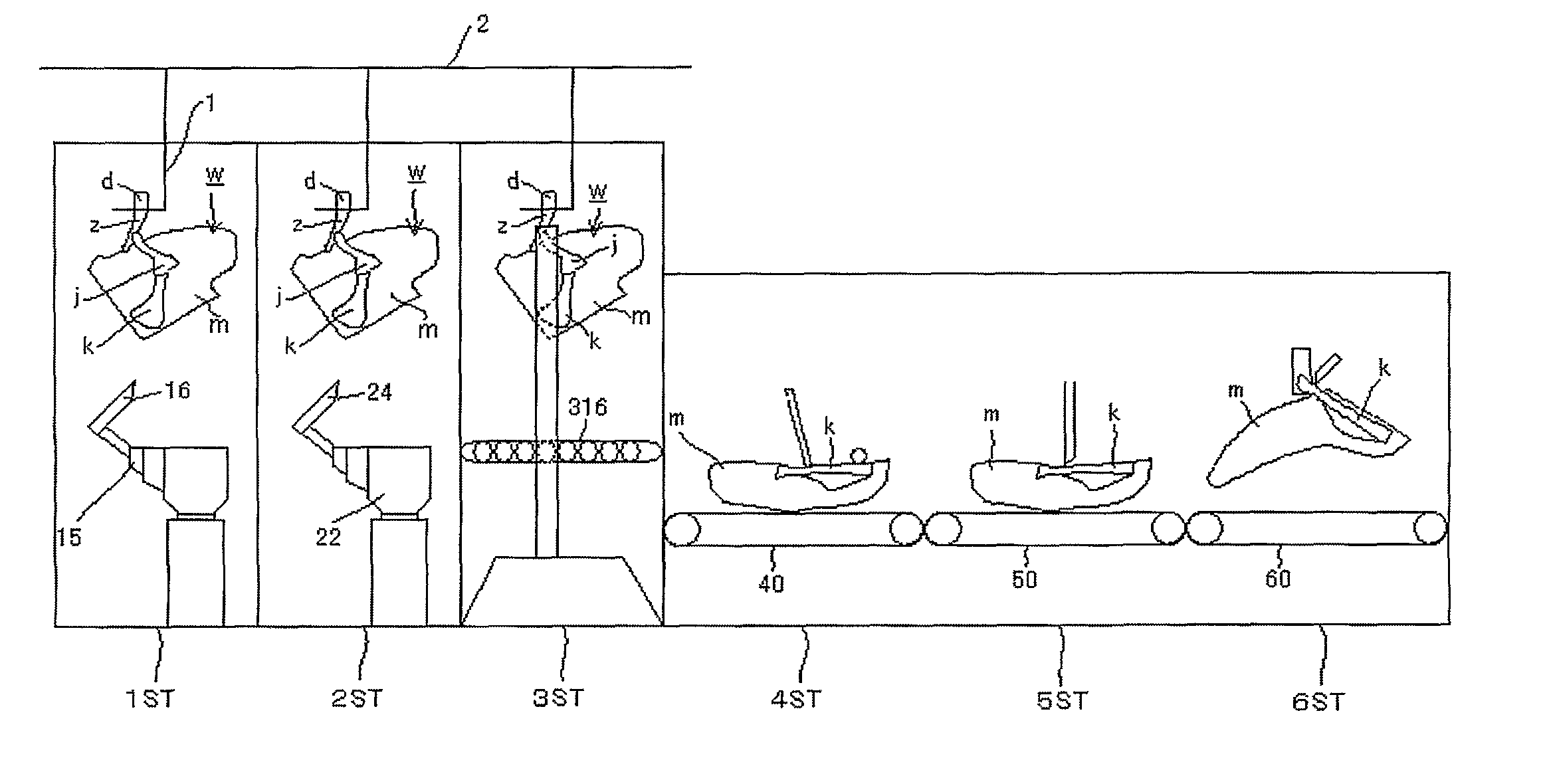

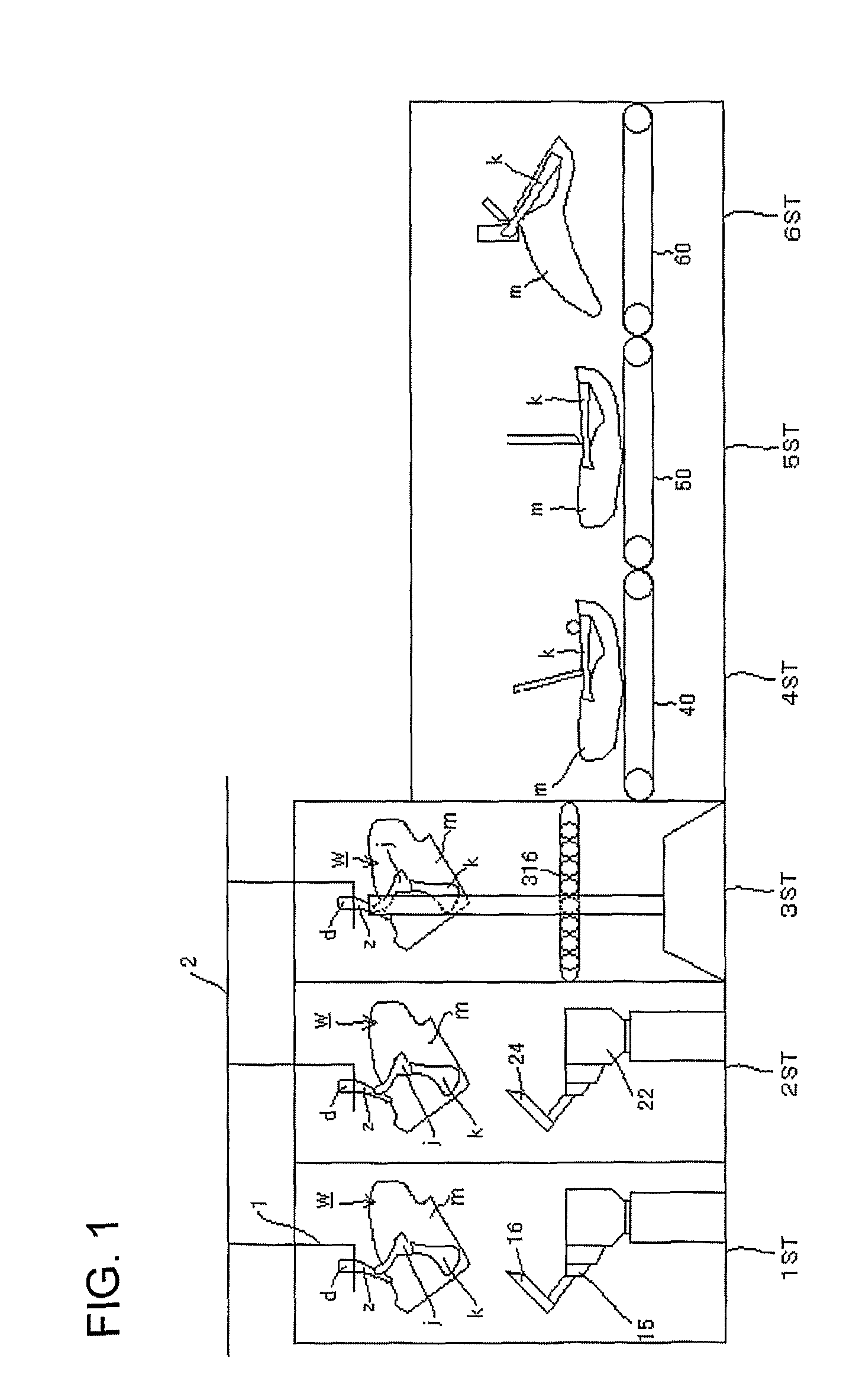

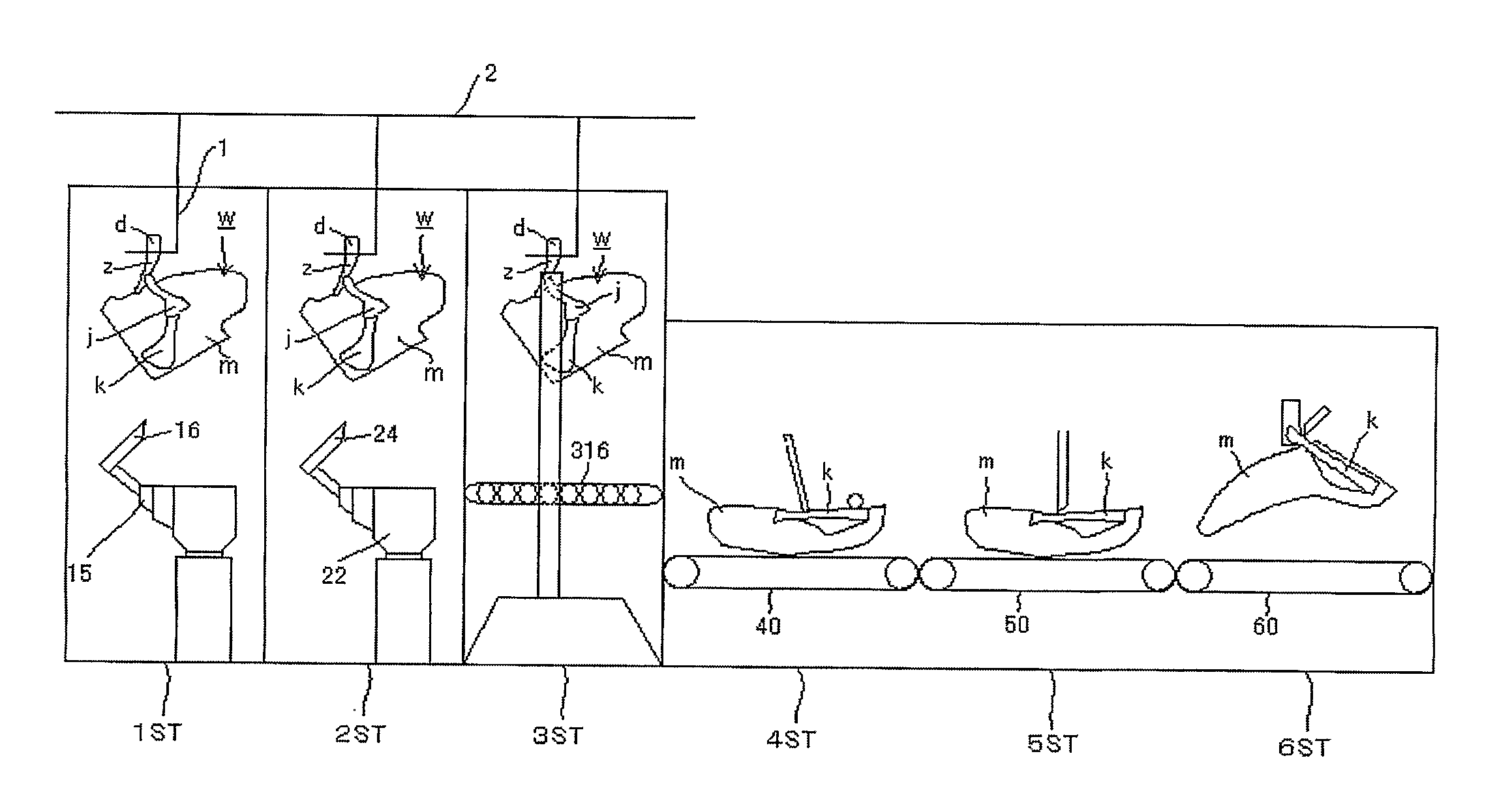

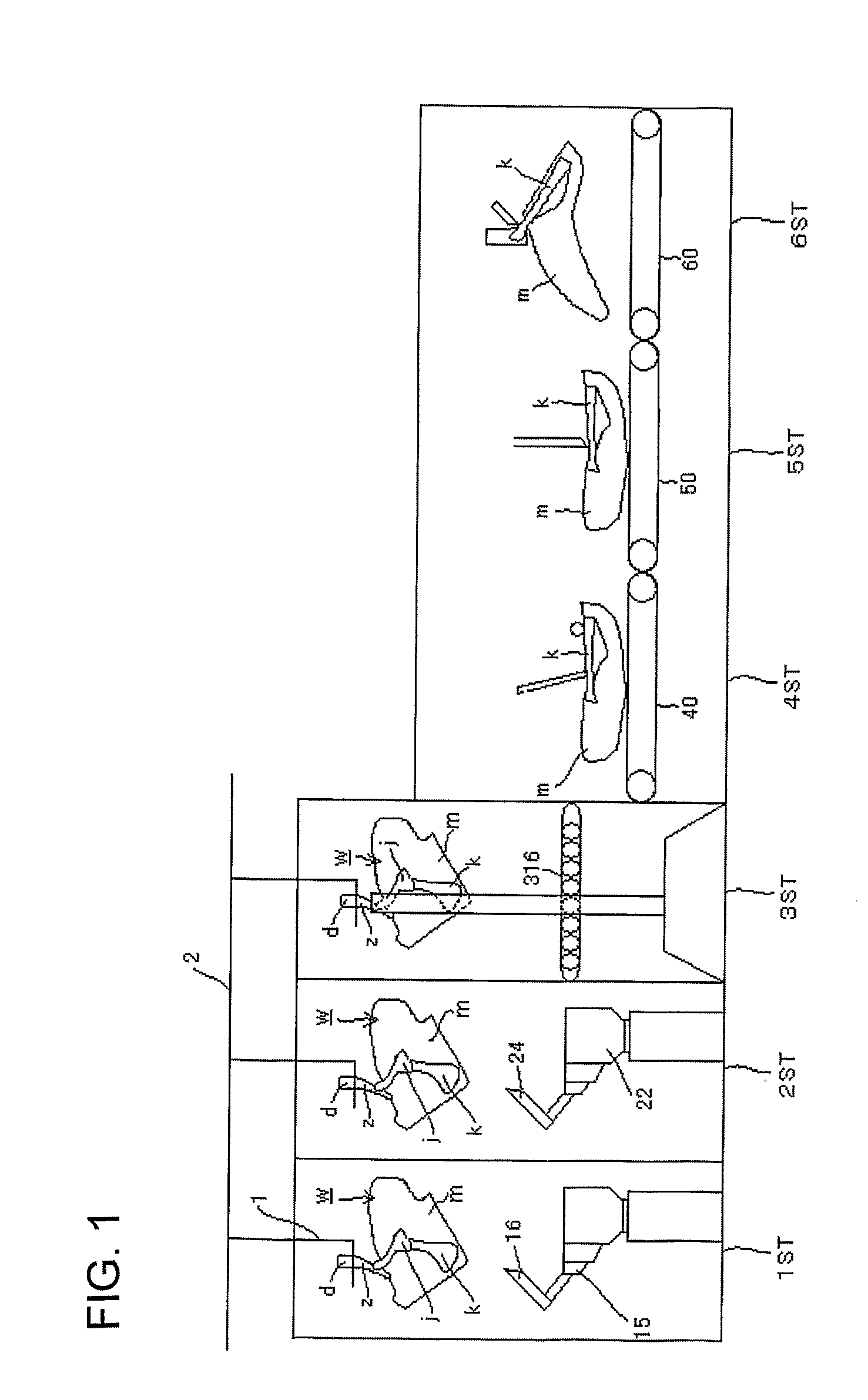

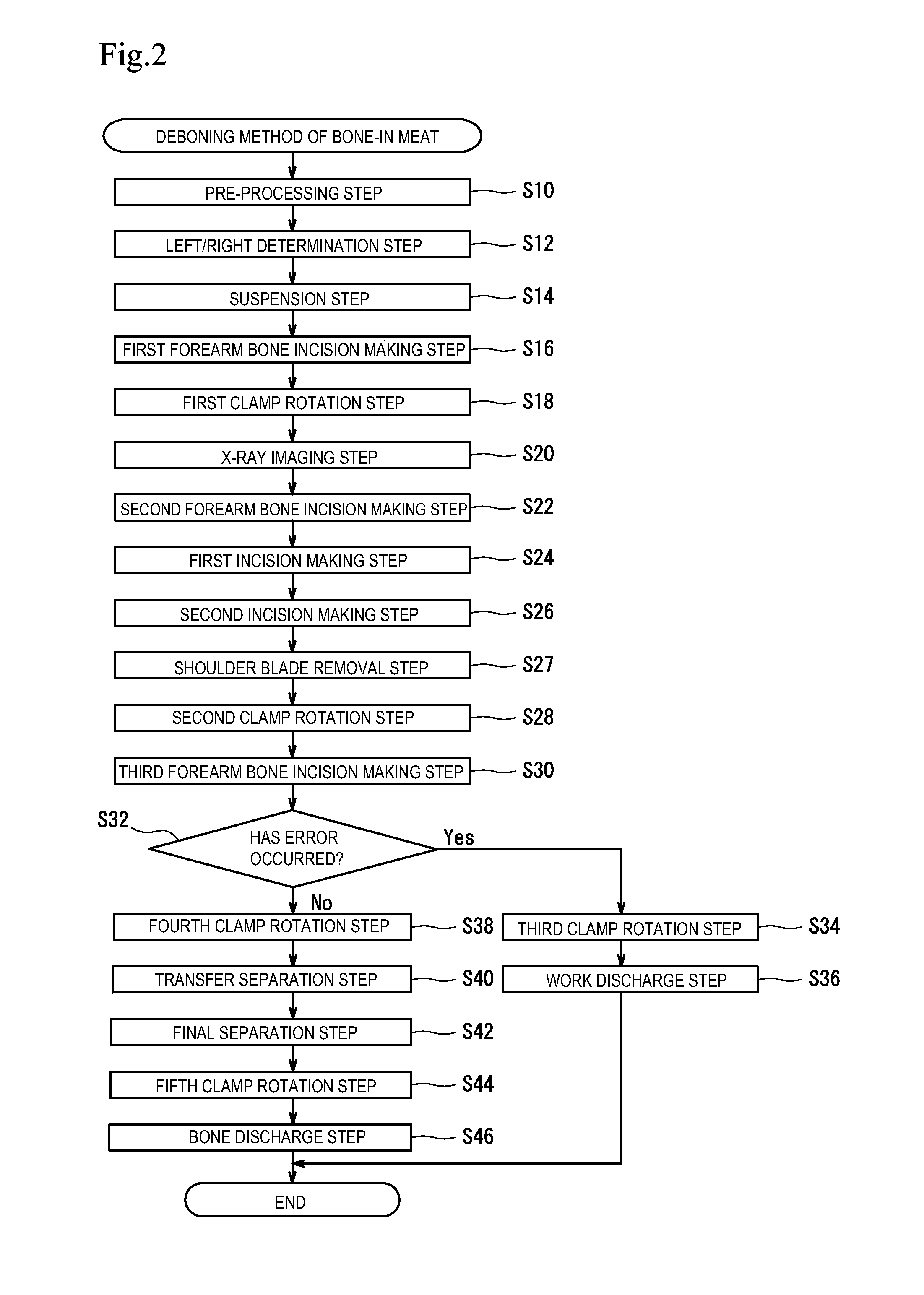

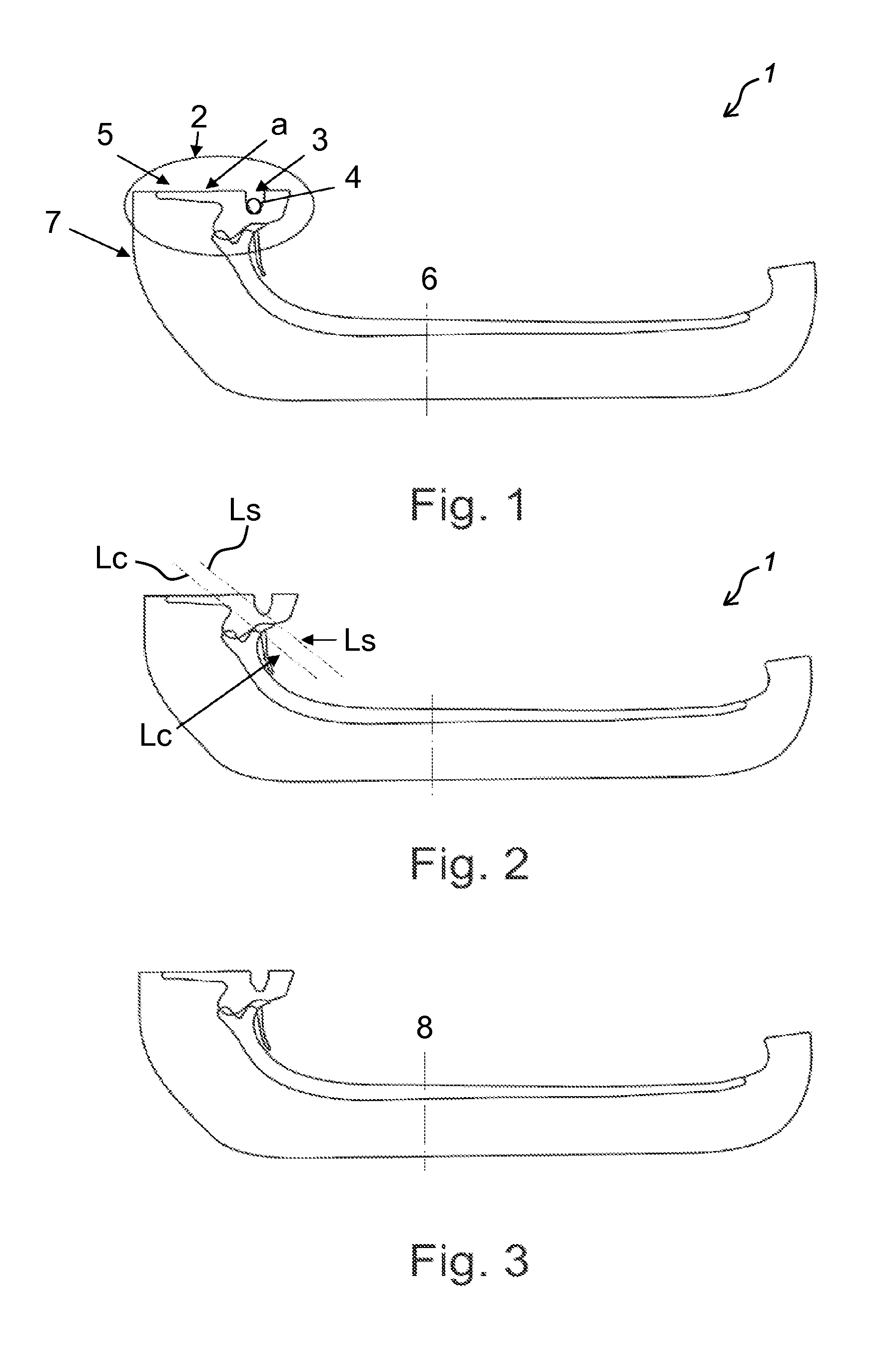

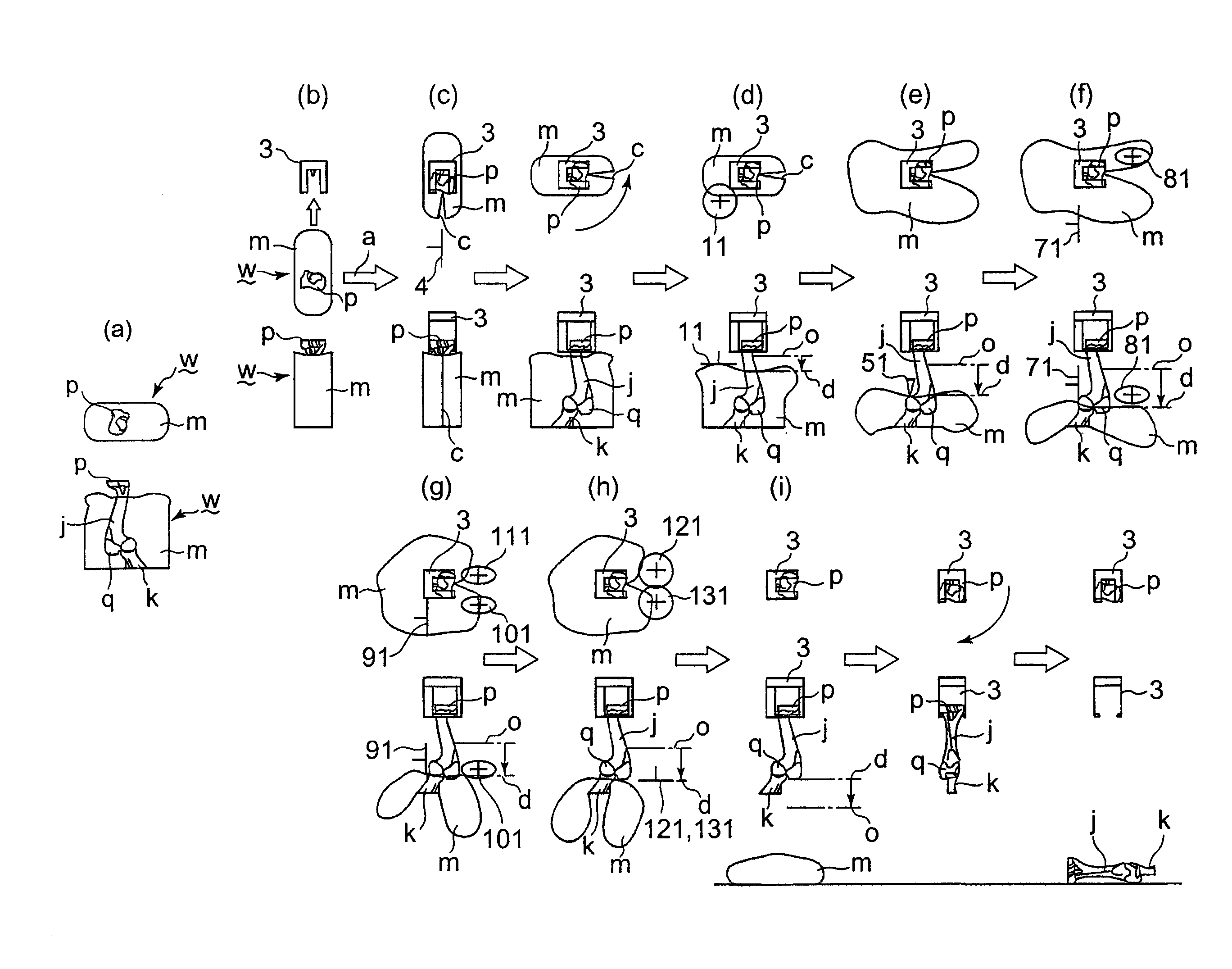

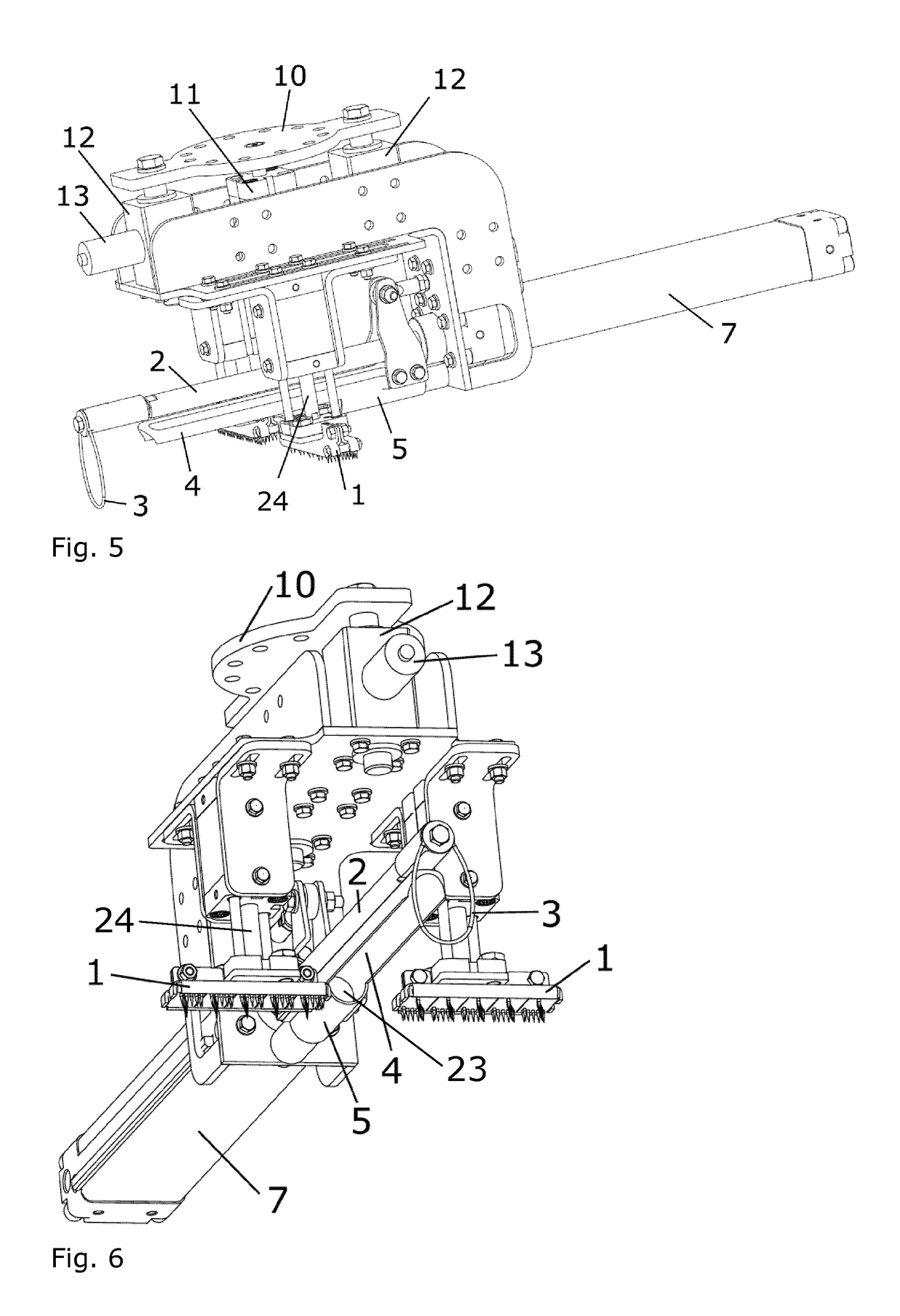

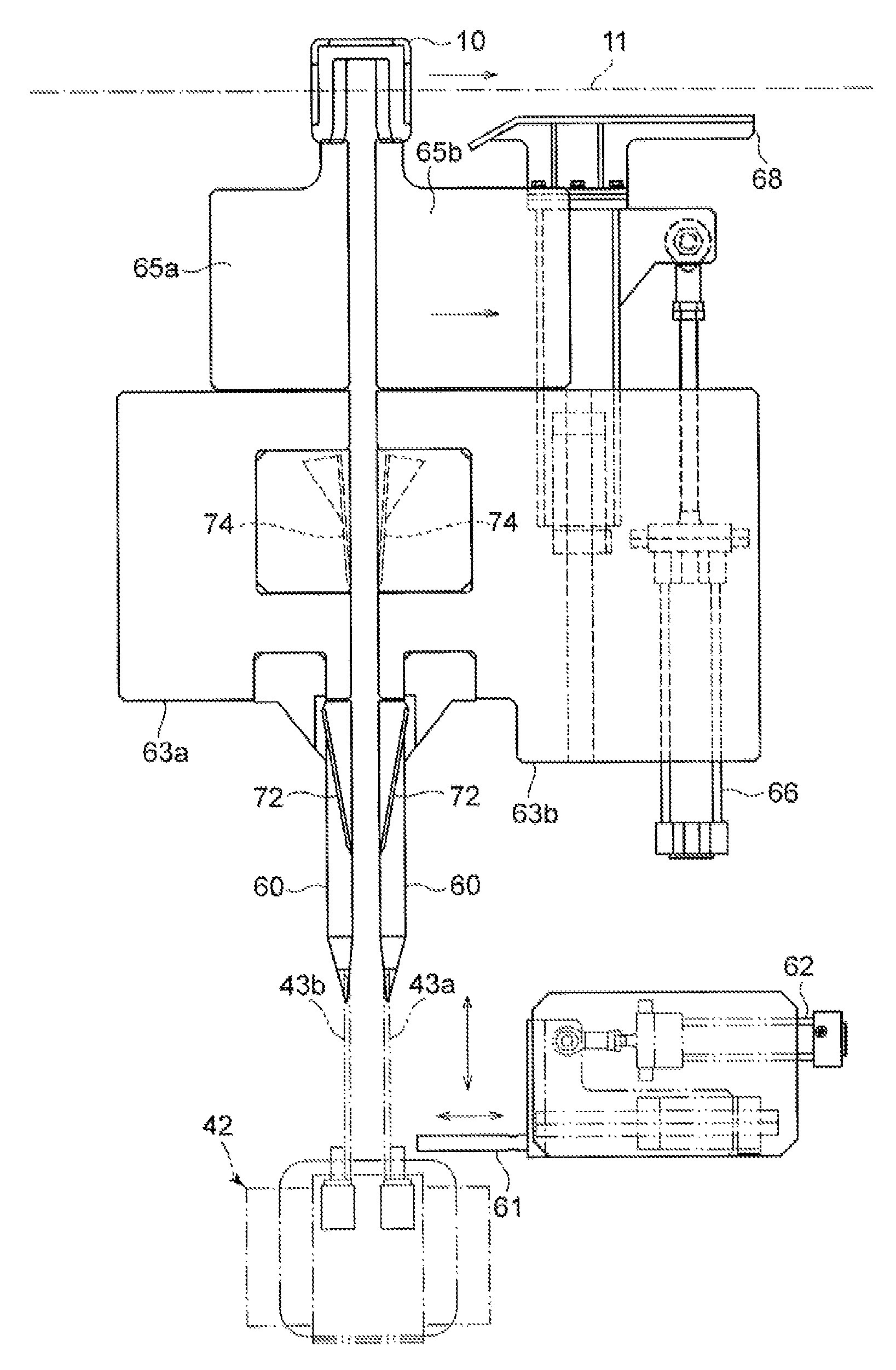

Automatic deboning method and apparatus for deboning bone laden meat

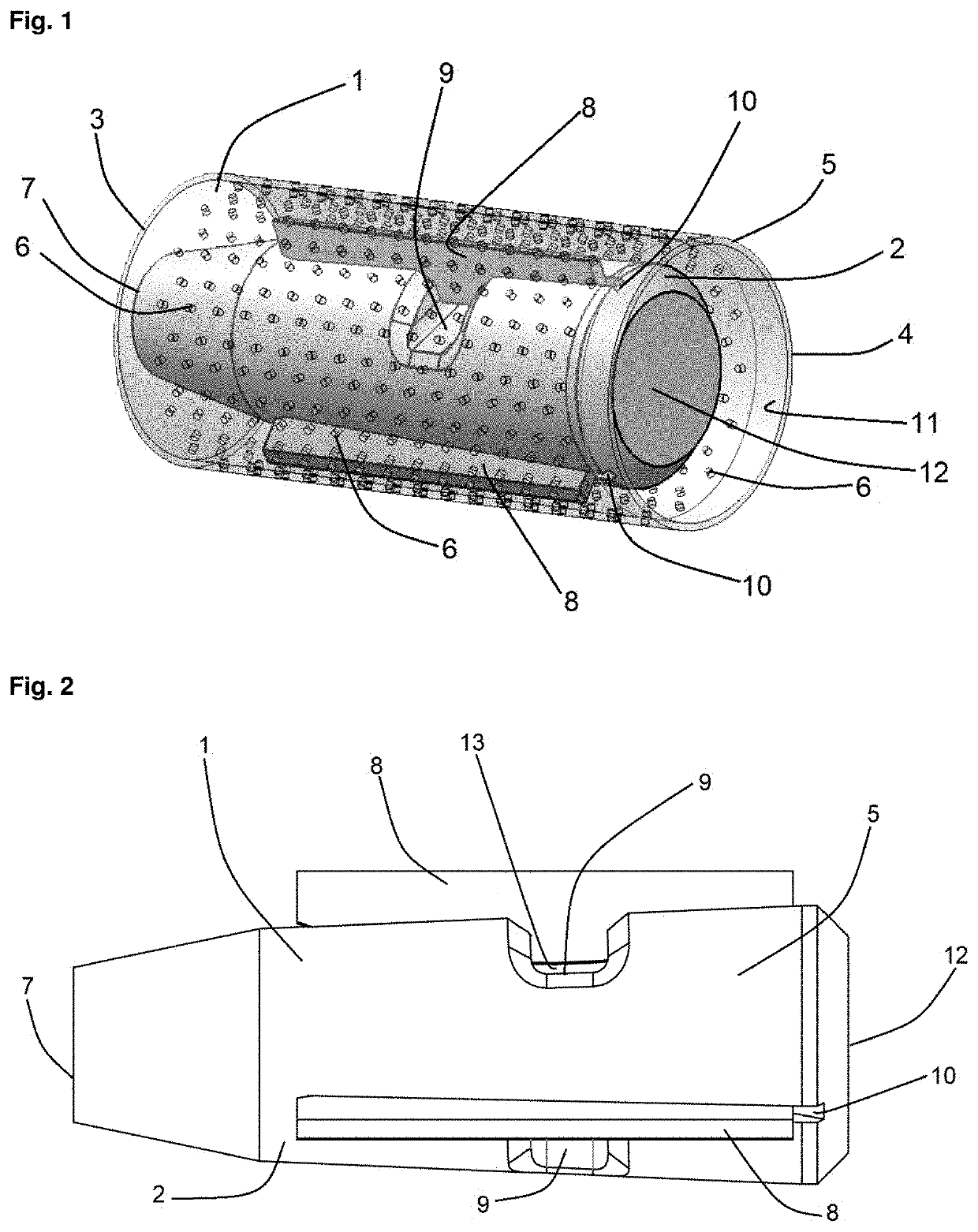

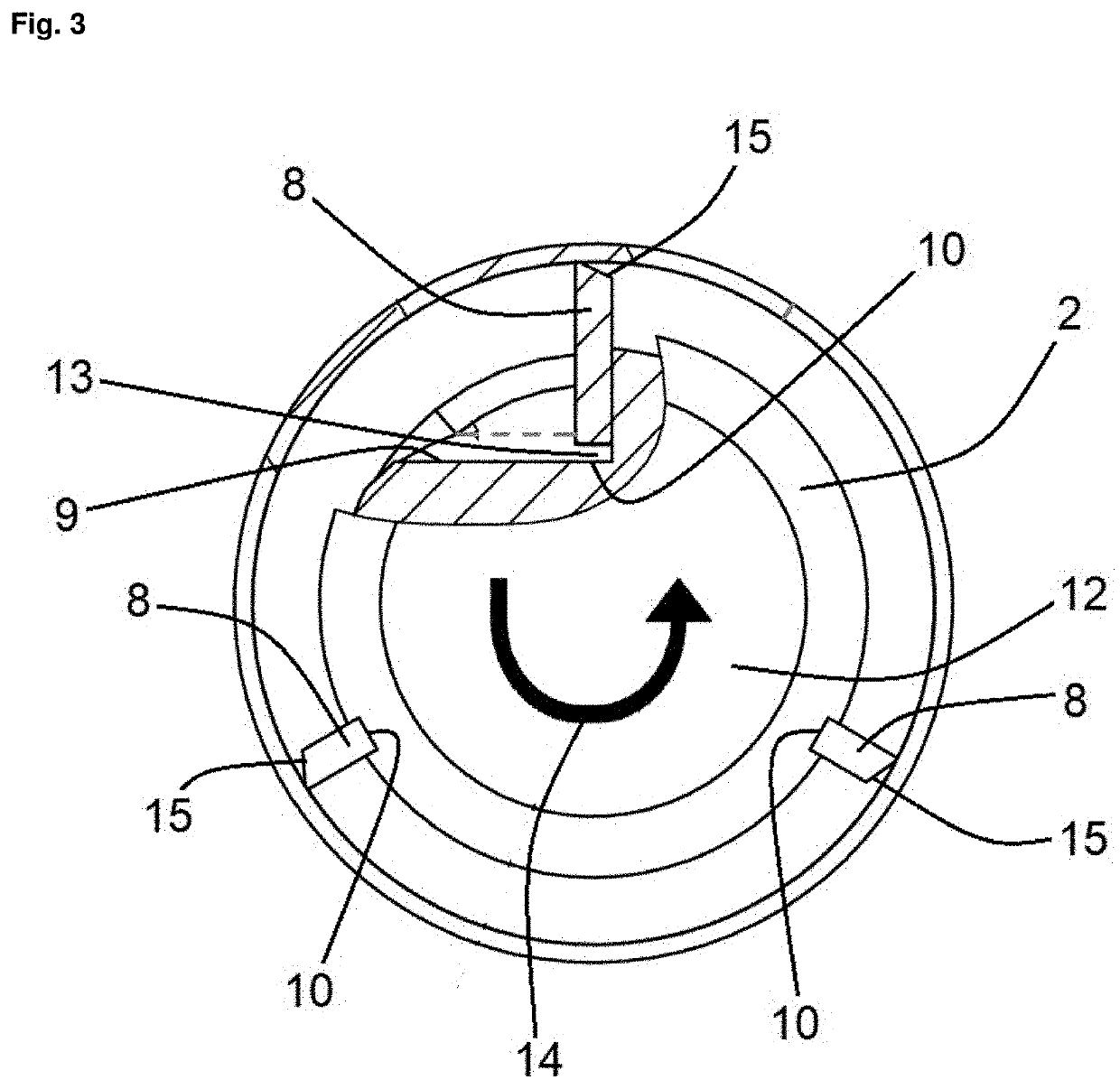

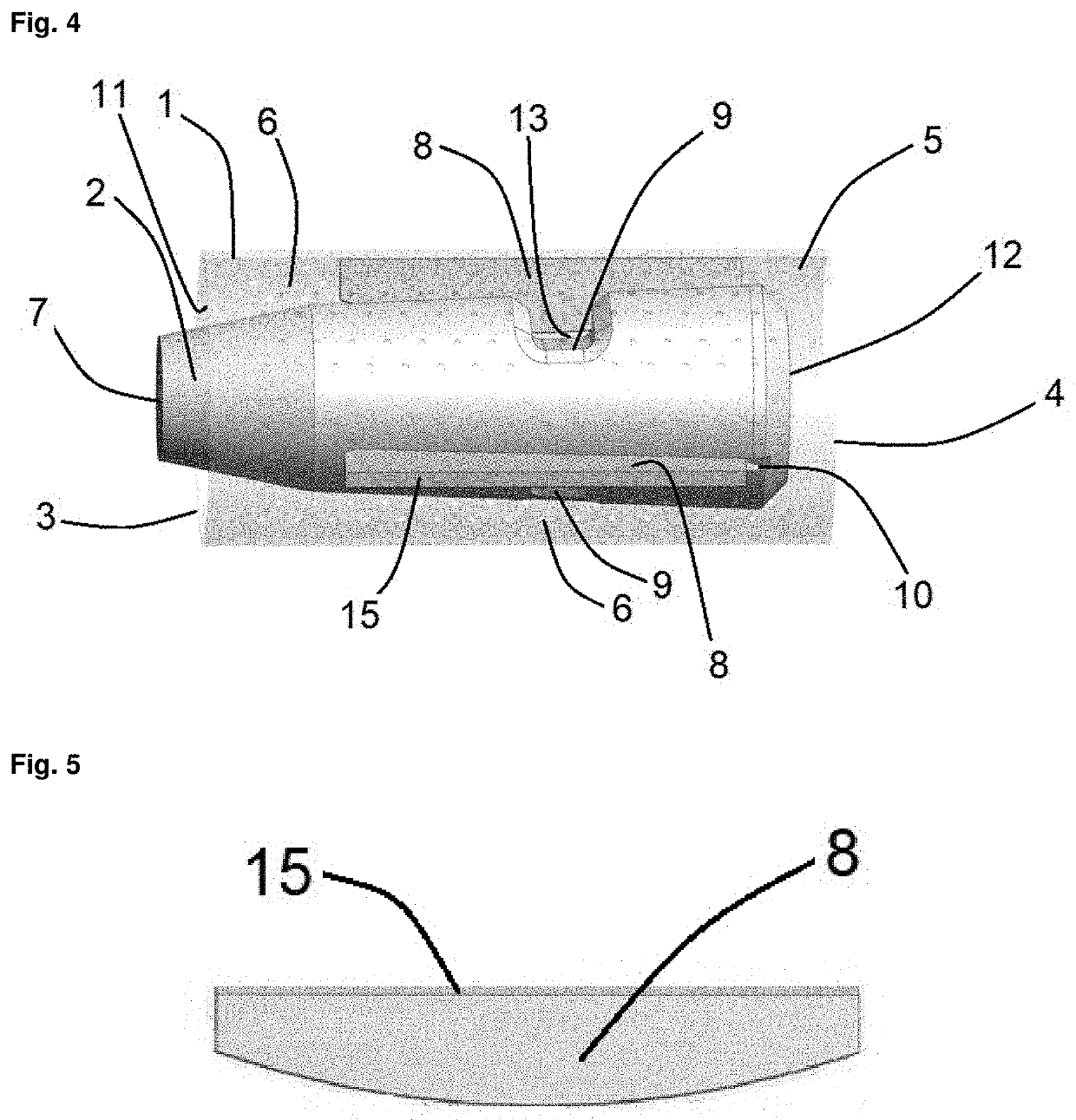

A de-boning method and apparatus for automating incision making to the meat of bone laden meat and scraping operation of meat from the bone laden meat by a meat separator, are proposed.The apparatus has a clamping device 1 for clamping an end part ‘d’ of unconcealed part of the bone of bone laden meat, a meat separator 31 having meat scraping plates 317a, 317b for pinching a bone of the bone laden meat, a cutter 33 located between the clamping device 1 and the meat separator 31, a clamping device lifting means 30, and rotation drive means 303 and 313 for rotating for rotating the clamping device 1 and the meat separator 31 in synchronism with each other, whereby spiral incision is made to a part of the meat of the bone laden meat by rotating the clamping device 1, and remaining part of the meat is scraped off as the clamping device is lifted while rotating in synchronism with the meat scraper.

Owner:MAYEKAWA MFG CO LTD

Automatic deboning method and apparatus for deboning bone laden meat

ActiveUS20090270021A1Easy to operateHigh degree of automationMeat holding apparatusBone cleaning devicesEngineeringBiomedical engineering

A de-boning method and apparatus for automating incision making to the meat of bone laden meat and scraping operation of meat from the bone laden meat by a meat separator, are proposed.The apparatus has a clamping device 1 for clamping an end part ‘d’ of unconcealed part of the bone of bone laden meat, a meat separator 31 having meat scraping plates 317a, 317b for pinching a bone of the bone laden meat, a cutter 33 located between the clamping device 1 and the meat separator 31, a clamping device lifting means 30, and rotation drive means 303 and 313 for rotating for rotating the clamping device 1 and the meat separator 31 in synchronism with each other, whereby spiral incision is made to a part of the meat of the bone laden meat by rotating the clamping device 1, and remaining part of the meat is scraped off as the clamping device is lifted while rotating in synchronism with the meat scraper.

Owner:MAYEKAWA MFG CO LTD

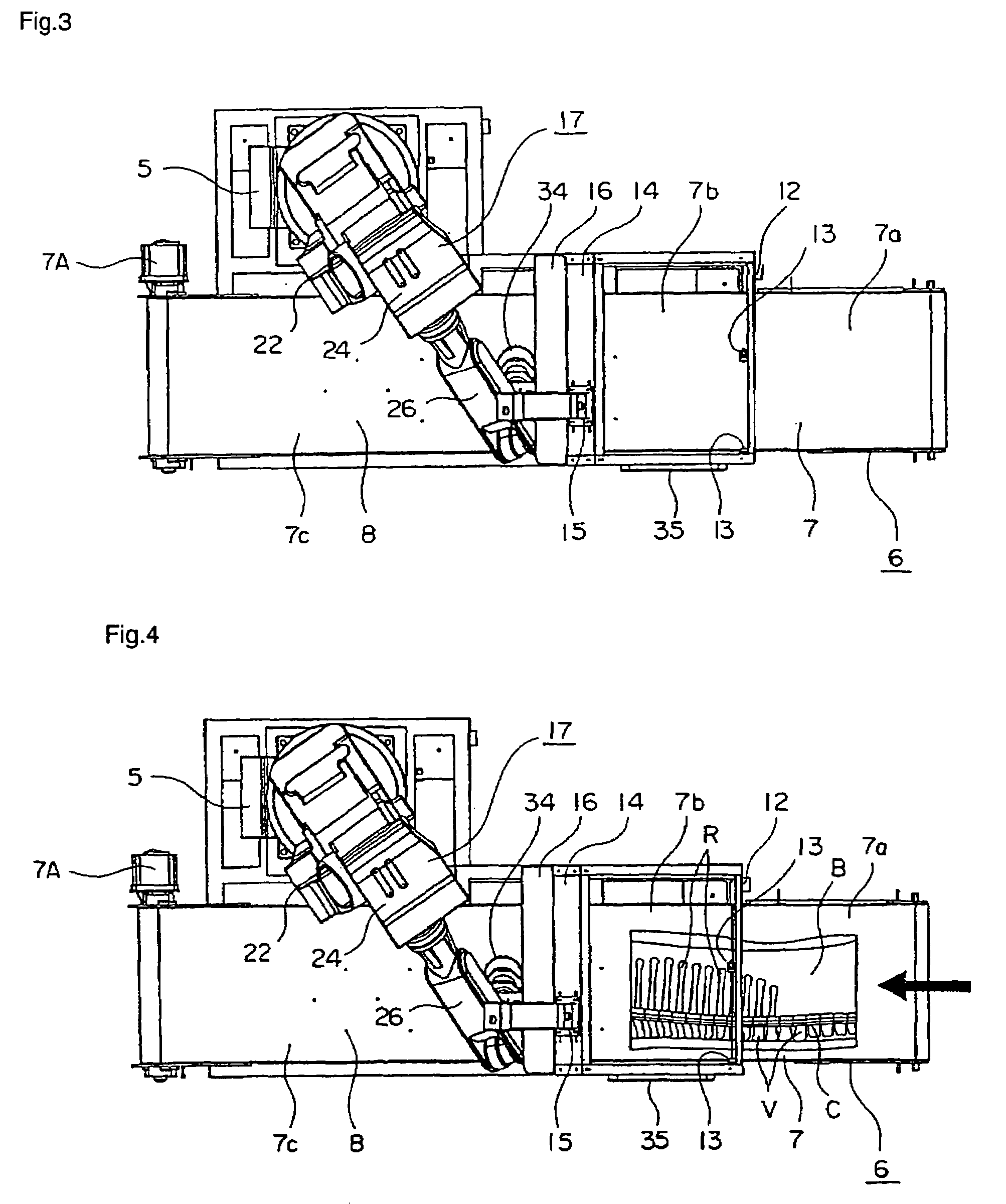

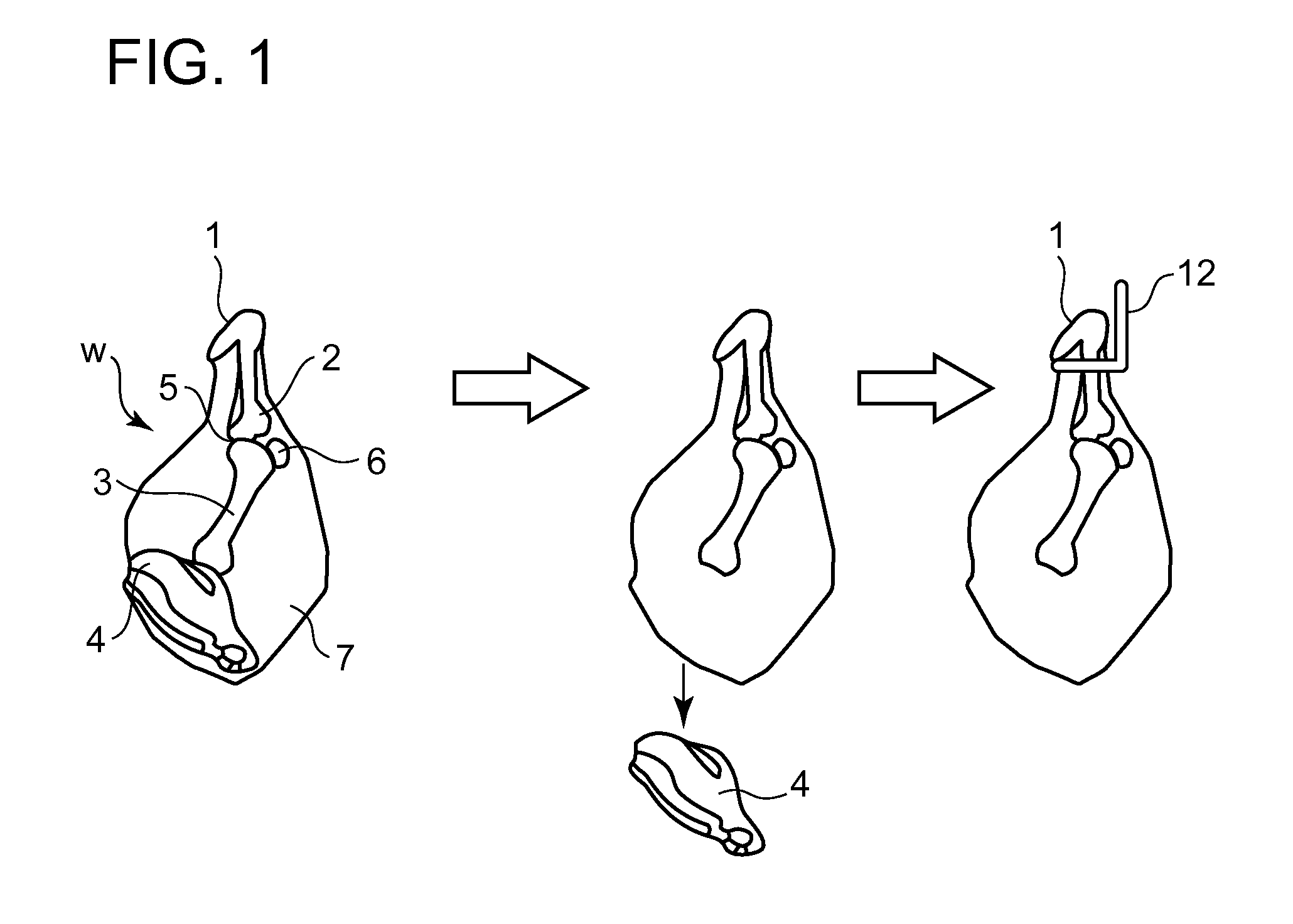

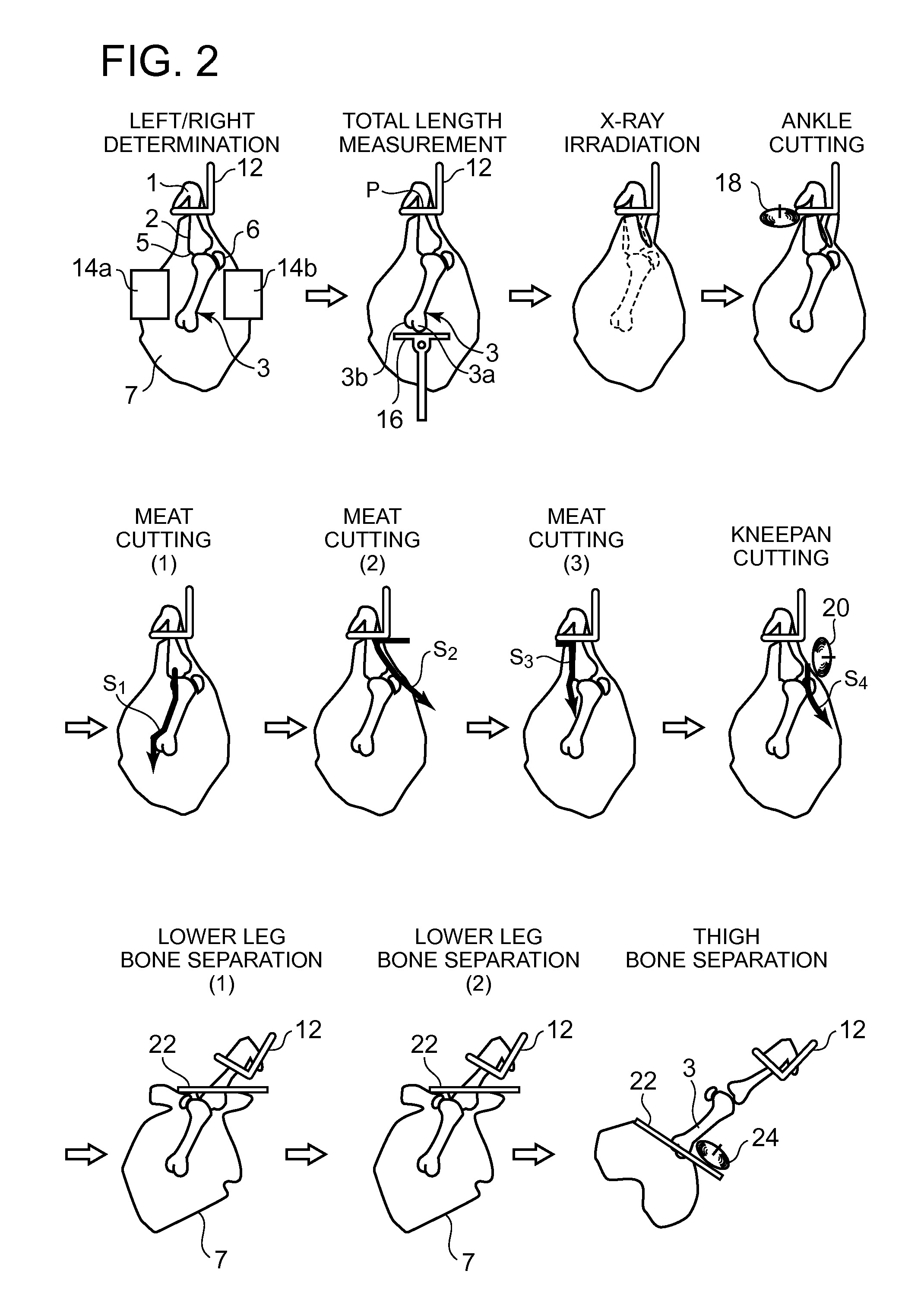

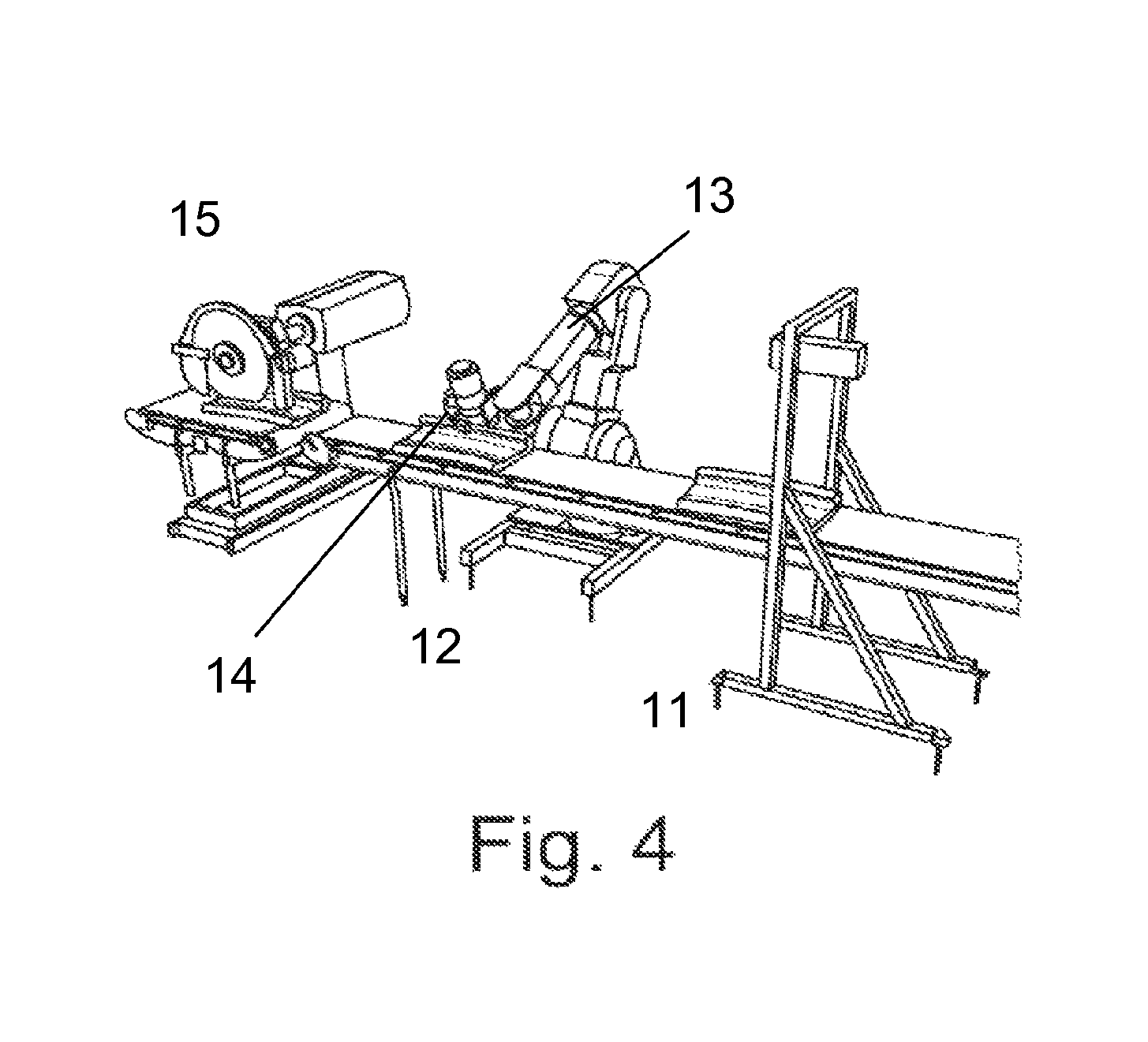

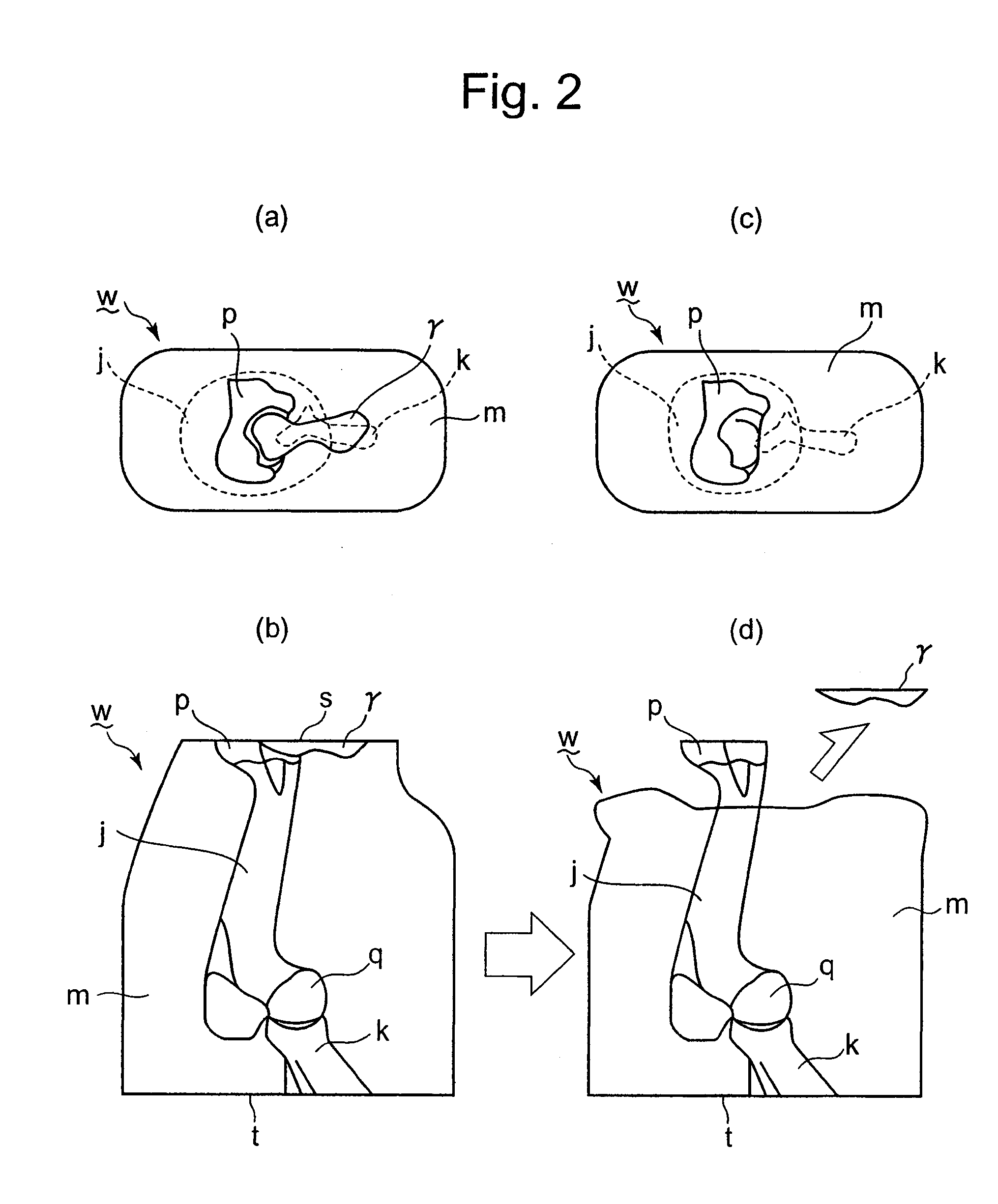

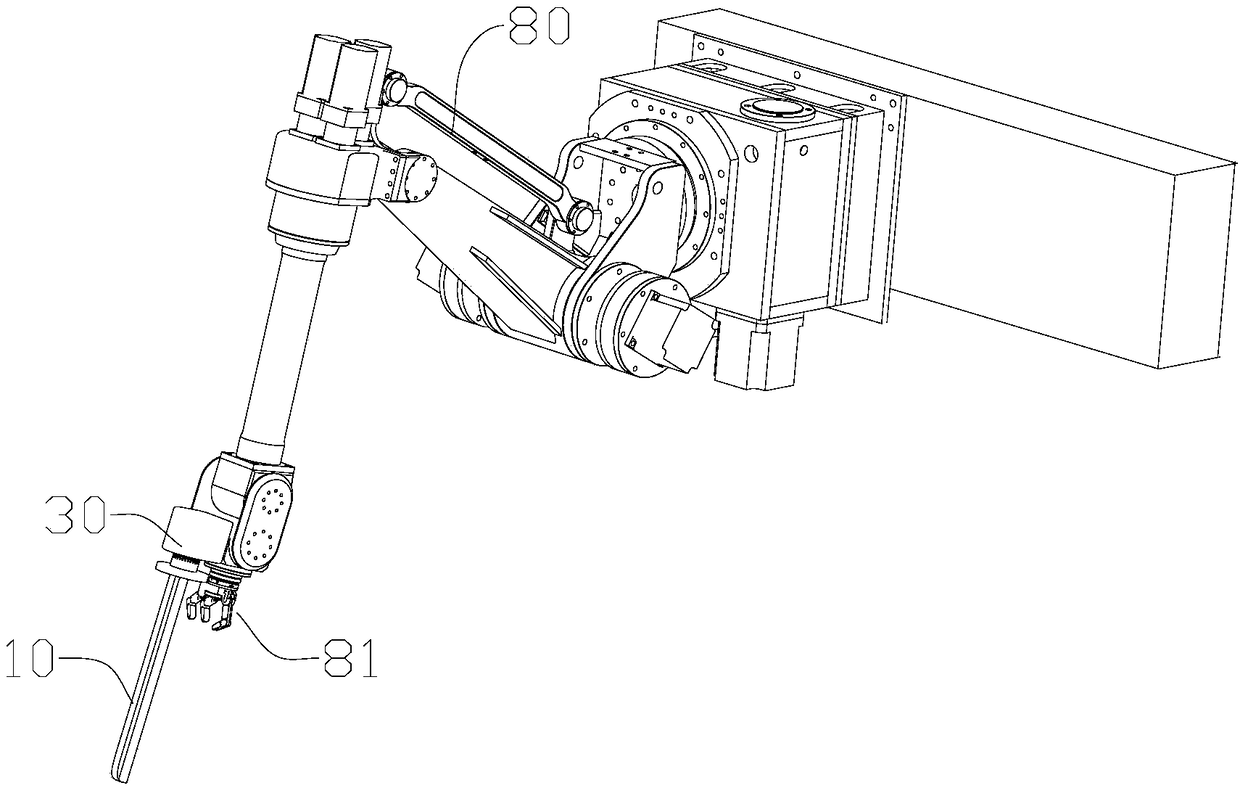

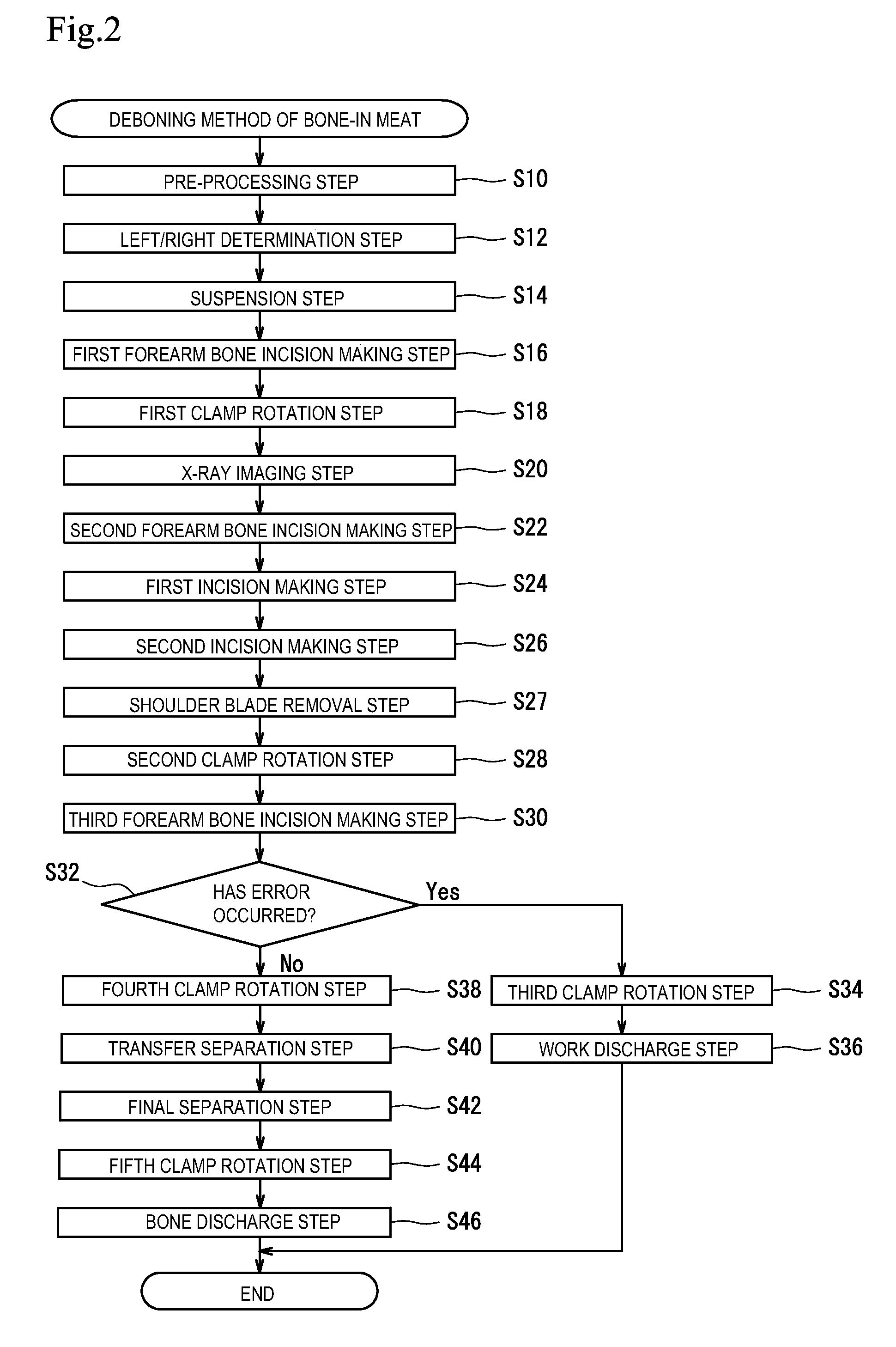

Deboning method and apparatus for meat with bone using X-ray

ActiveUS8376814B2Reduce harmIncrease loadPoultry processingFish filletingImaging processingImaging analysis

In an automatic deboning apparatus, an X-ray irradiation unit is provided on the upstream side of a meat cutting unit in a direction of transport of the work. In the X-ray irradiation unit, an X-ray r is irradiated to a work w from an X-ray irradiation device, an image of the X-ray transmitted through the work is subjected to image processing in an image analysis process unit, and two-dimensional position coordinates of a bone part are thereby obtained. In the meat cutting unit, three robot arms are provided with cutting blades. A storage unit of a controller stores three-dimensional position coordinates of a target operation course of each of the cutting blades. The target operation course is corrected on the basis of the two-dimensional position coordinates of the bone part obtained for each work in the image analysis process unit.

Owner:MAYEKAWA MFG CO LTD

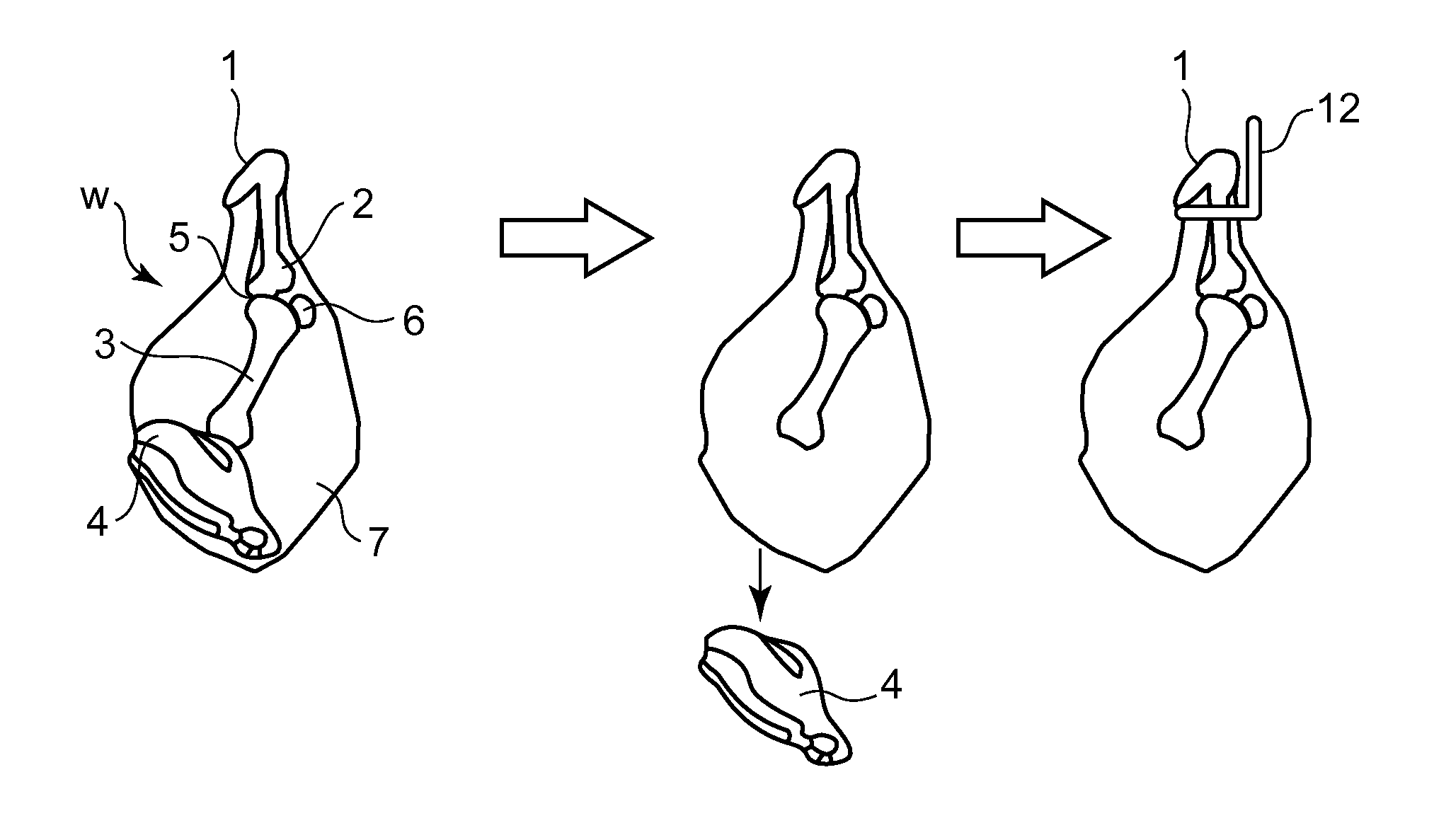

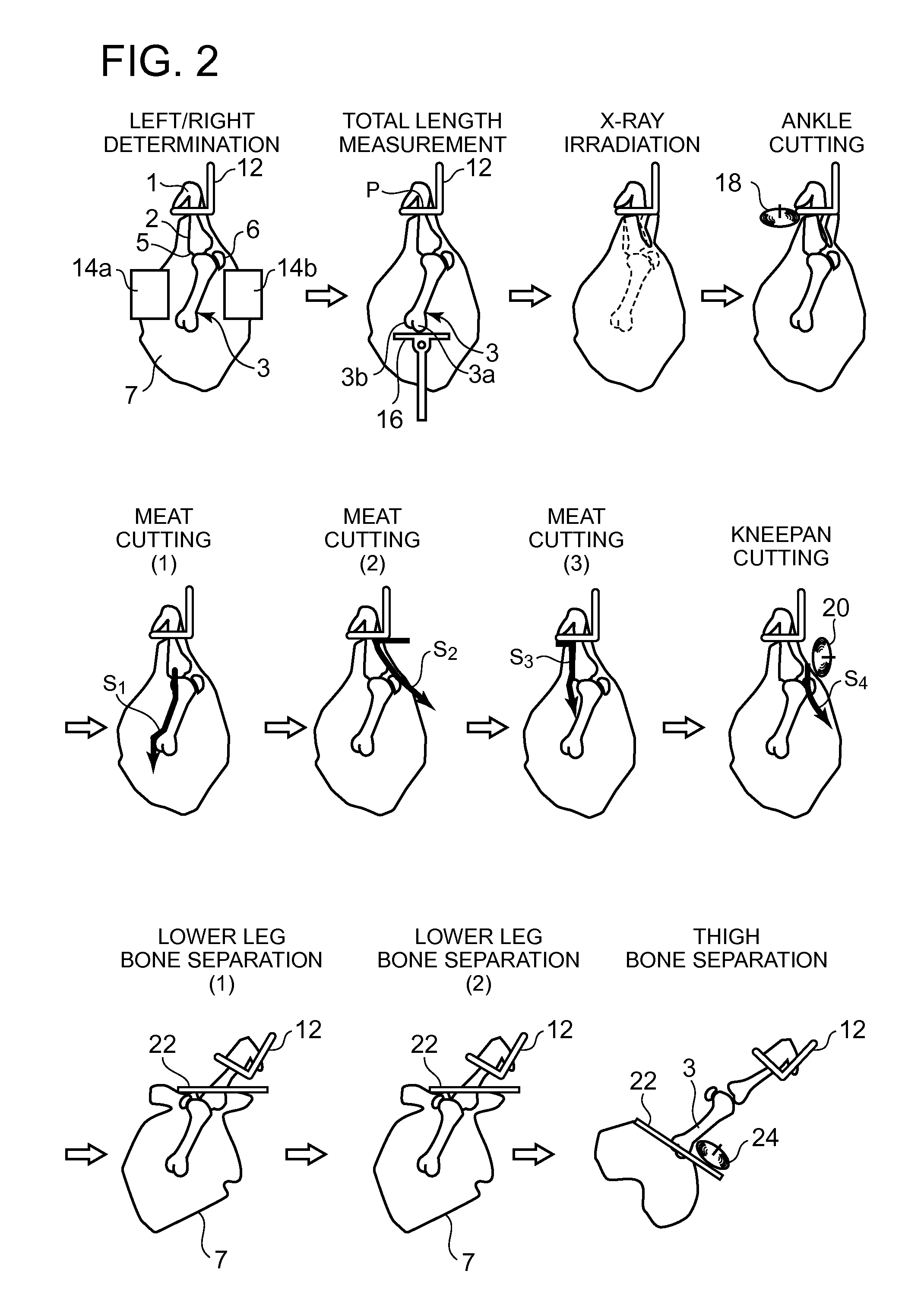

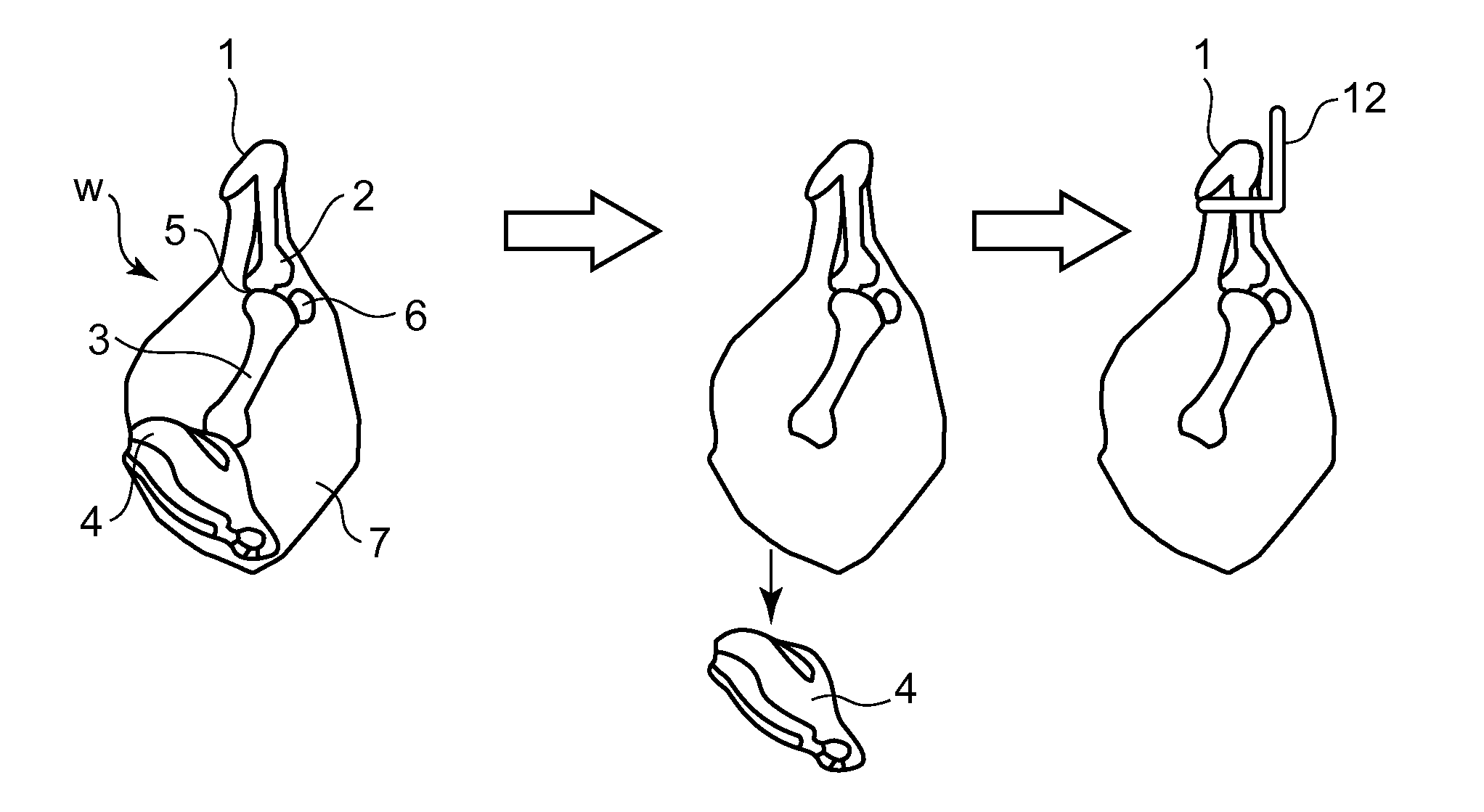

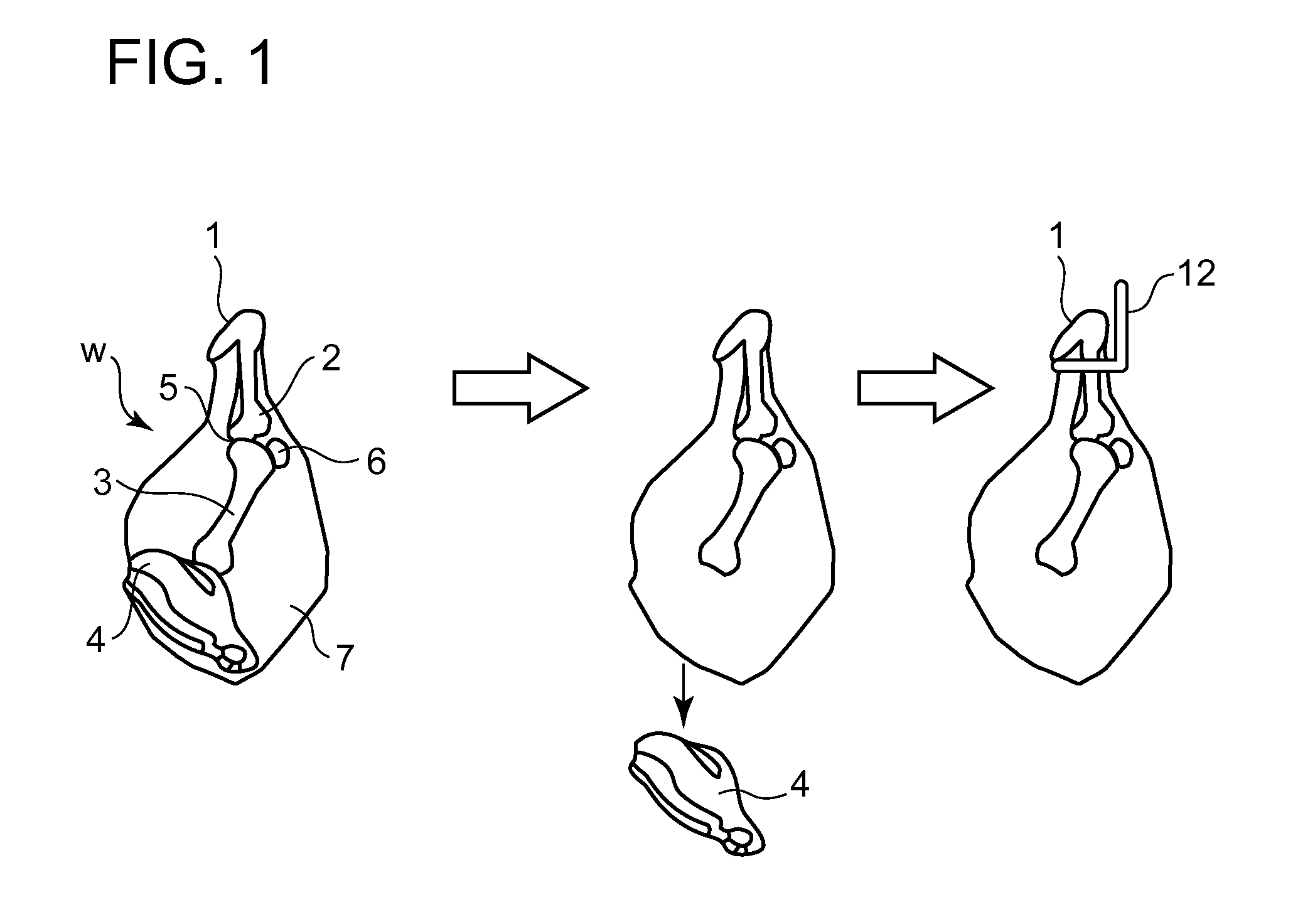

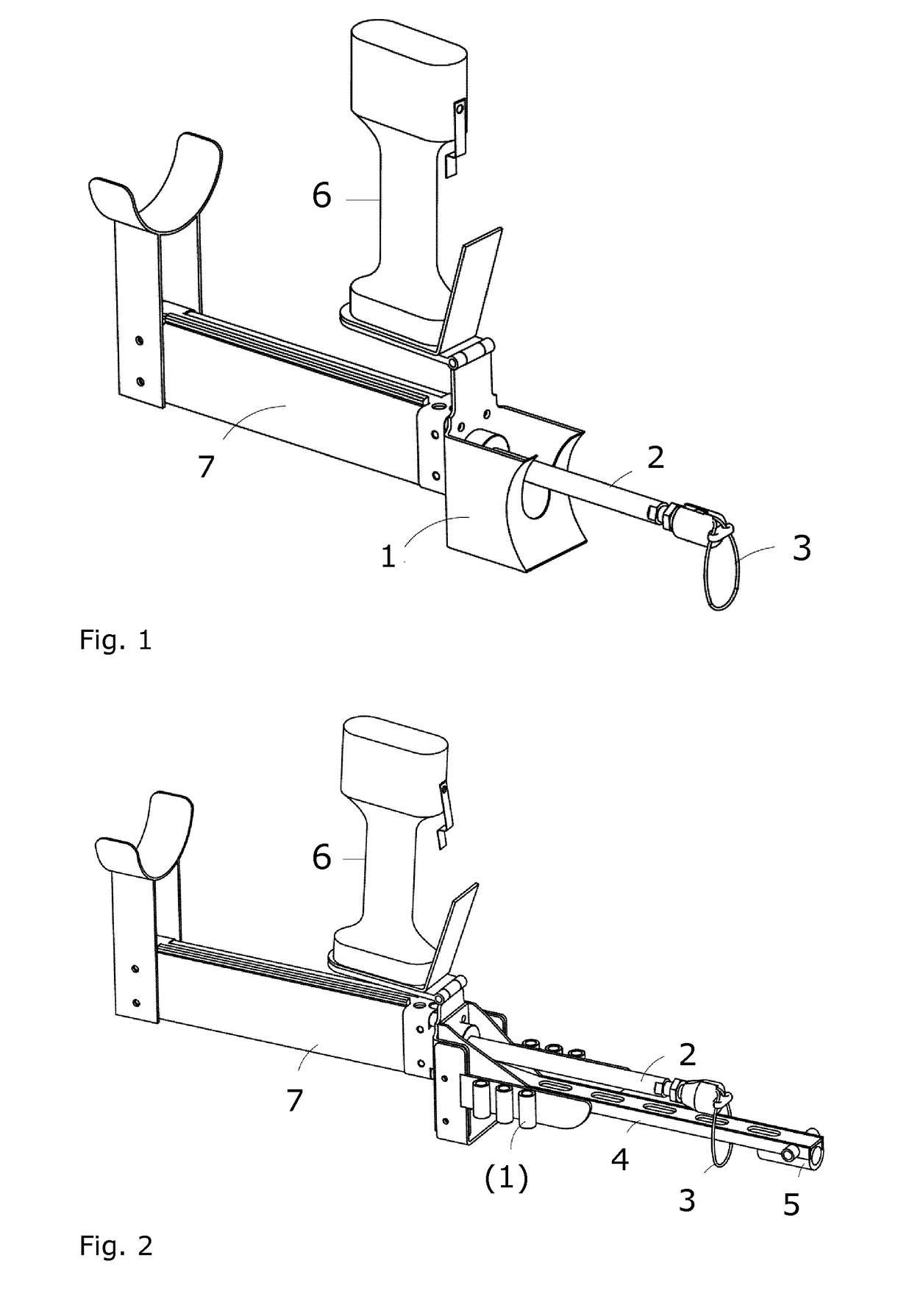

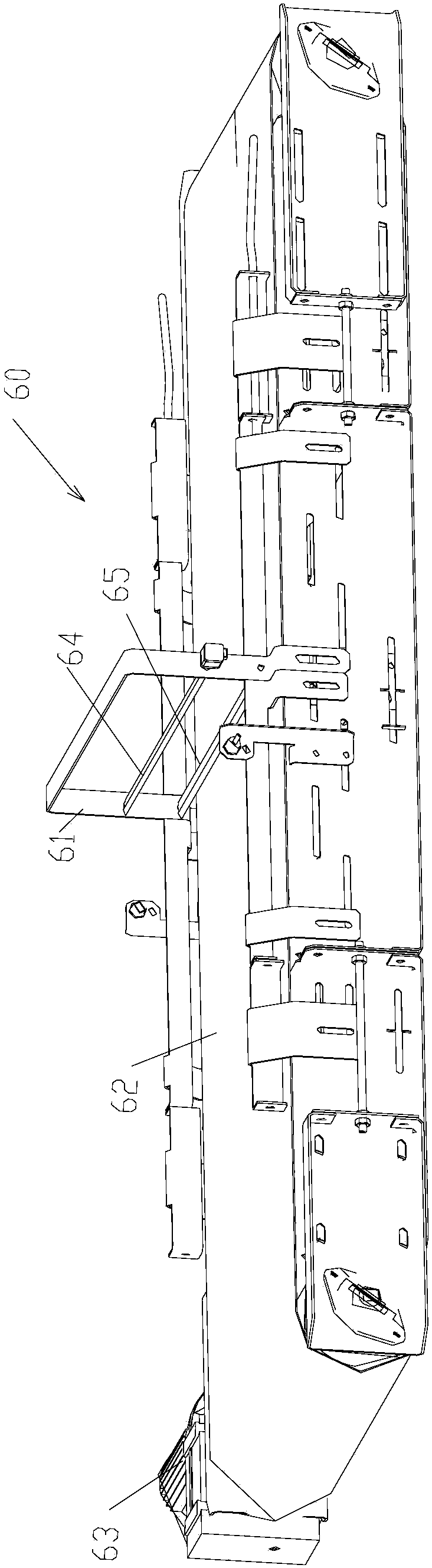

Device and method for conveying bone-in meat and deboning system of bone-in meat including the device

ActiveUS20150004892A1Increase automation rateMeat/sausage hanging-upSlaughtering animals fettering apparatusBand shapeActuator

Two hooking members of a hooking unit used in a device for conveying bone-in meat respectively have belt-like main body parts, blade-like pointed ends provided at ends on one side of the main body parts, and barbs provided on first sides of the main body parts to be continuous with the points. The hooking members are supported so as to be in parallel with each other with an elastically changeable interval therebetween and to be rotatable about rotation axes along longitudinal axes of the main body parts. Further, the hooking unit has an actuator which rotates the hooking members about the rotation axes.

Owner:MAYEKAWA MFG CO LTD

Deboning method and apparatus for meat with bone using x-ray

ActiveUS20120295527A1Increase productionAvert excessive load appliedPoultry processingFish filletingImaging processingImaging analysis

In an automatic deboning apparatus, an X-ray irradiation unit is provided on the upstream side of a meat cutting unit in a direction of transport of the work. In the X-ray irradiation unit, an X-ray r is irradiated to a work w from an X-ray irradiation device, an image of the X-ray transmitted through the work is subjected to image processing in an image analysis process unit, and two-dimensional position coordinates of a bone part are thereby obtained. In the meat cutting unit, three robot arms are provided with cutting blades. A storage unit of a controller stores three-dimensional position coordinates of a target operation course of each of the cutting blades. The target operation course is corrected on the basis of the two-dimensional position coordinates of the bone part obtained for each work in the image analysis process unit.

Owner:MAYEKAWA MFG CO LTD

Method and apparatus for tenderizing meat

InactiveUS20050221746A1Increased meat tendernessEasy to separatePulse automatic controlElectric-based meat tenderisingFiberMuscle tissue

A method for tenderizing meat of a red meat slaughter animal includes separating a vertebra of the animal and applying electrical stimulation to the animal's musculature. The vertebra separating is performed prior to the onset of rigor mortis to enable stretching of muscle fibers in the carcass. The electrical stimulation is focused on a midsection of the animal.

Owner:CARGILL INC

Flesh separating machine

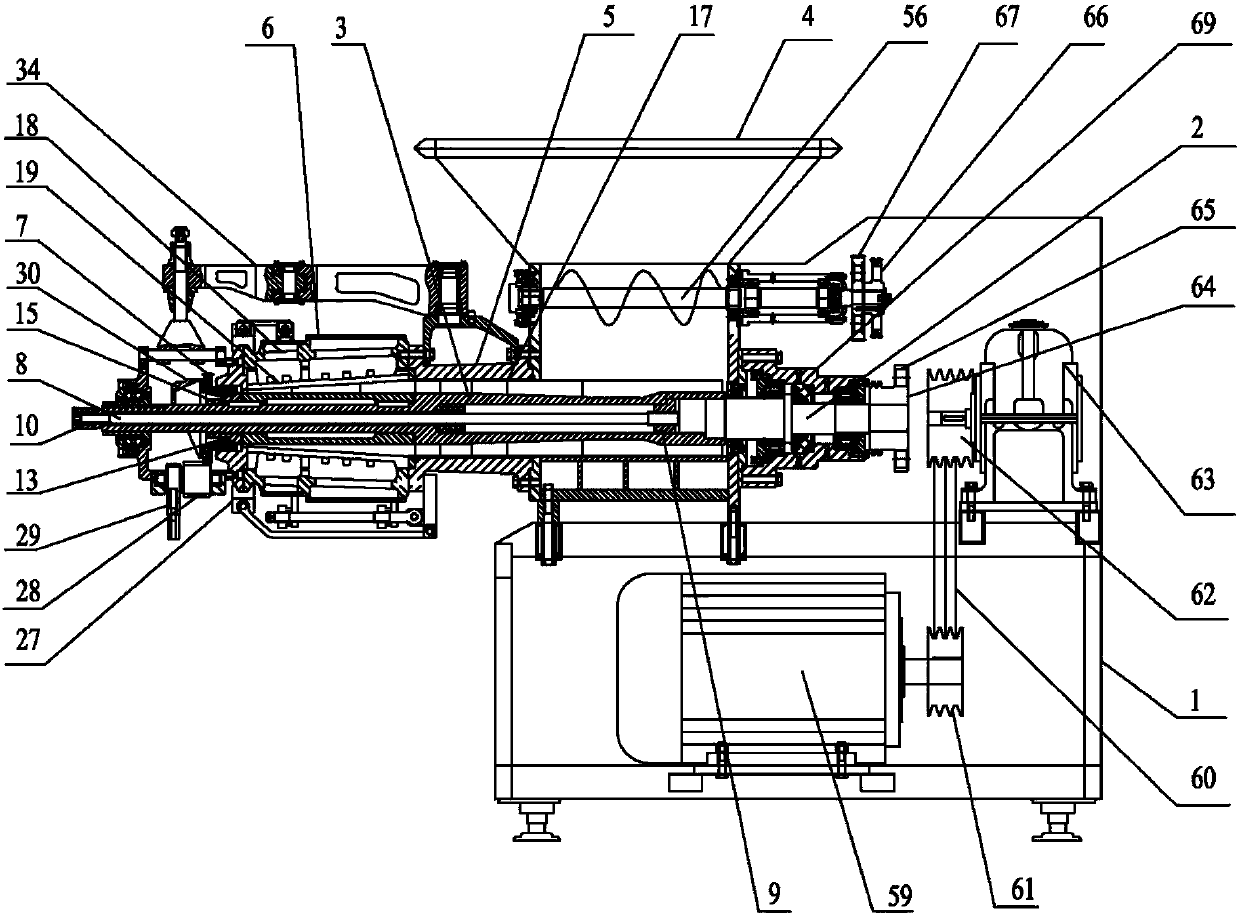

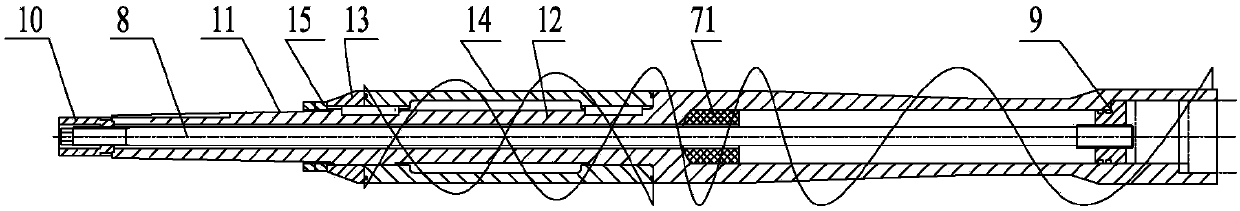

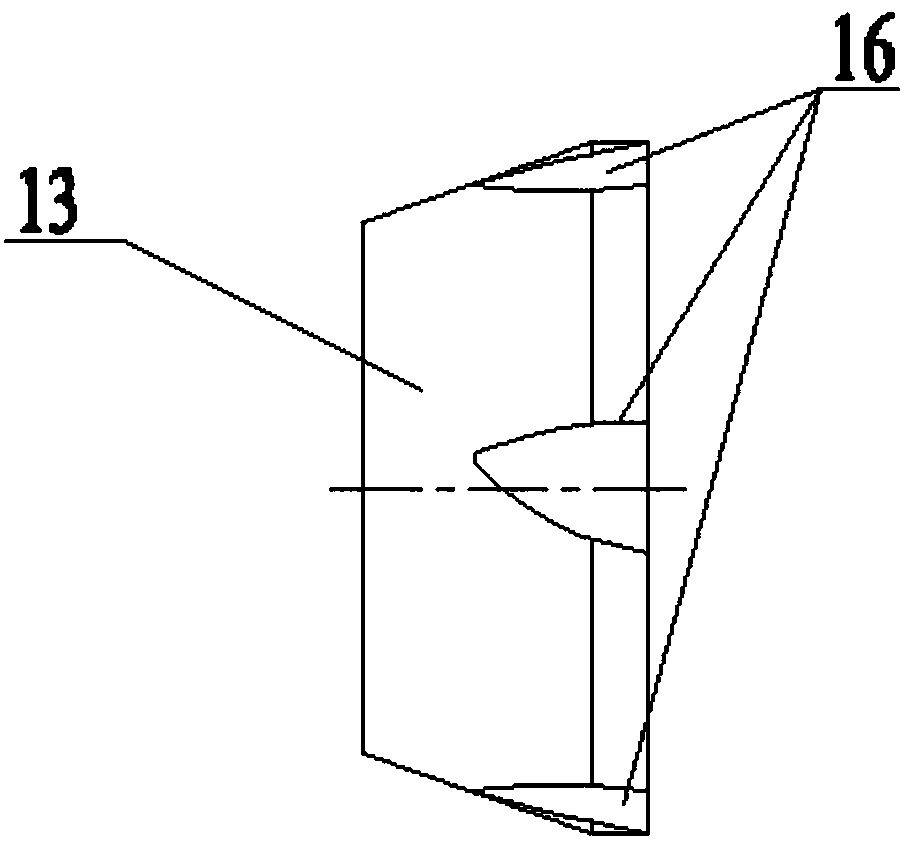

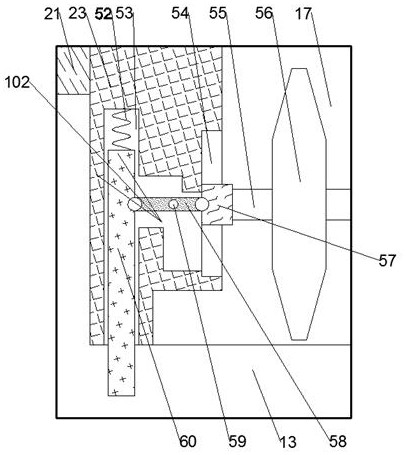

ActiveCN107690282AEasy to separateImprove separation rateBone cleaning devicesPoultry deboningDrive shaftEngineering

The invention discloses a flesh separating machine which comprises a machine frame, a driving mechanism, a transmission shaft, a screw shaft, a feeding hopper, a pressurizing part and a flesh separating part. The separating screw shaft part is a conical screw shaft, and the flesh separating part is also a conical component coaxially sleeved on the outer periphery of the separating screw shaft; theinner wall of the separation screw shaft is provided with a clearance fit with the outer wall of the separation screw shaft part; the side wall of one end of the separation part near the pressurizingpart is provided with a clearance gap; a control valve is arranged on the outer periphery of the front end of the separation screw shaft part and the front end of the separation screw shaft part; a slag discharge gap is arranged; the screw shaft is a hollow screw shaft which is internally provided with an adjusting rod; one end of the transmission shaft is fixedly provided with a connecting part.One end of the adjusting rod is screwed with the connecting part, and the other end of the adjusting rod extends out of the screw shaft and extends out of the flesh separating part. The flesh separating machine makes the inner wall of the flesh separation part and the outer wall of the spiral shaft always in a relatively stable gap fit state, which improves the service life.

Owner:SUNBY MACHINERY CO LTD

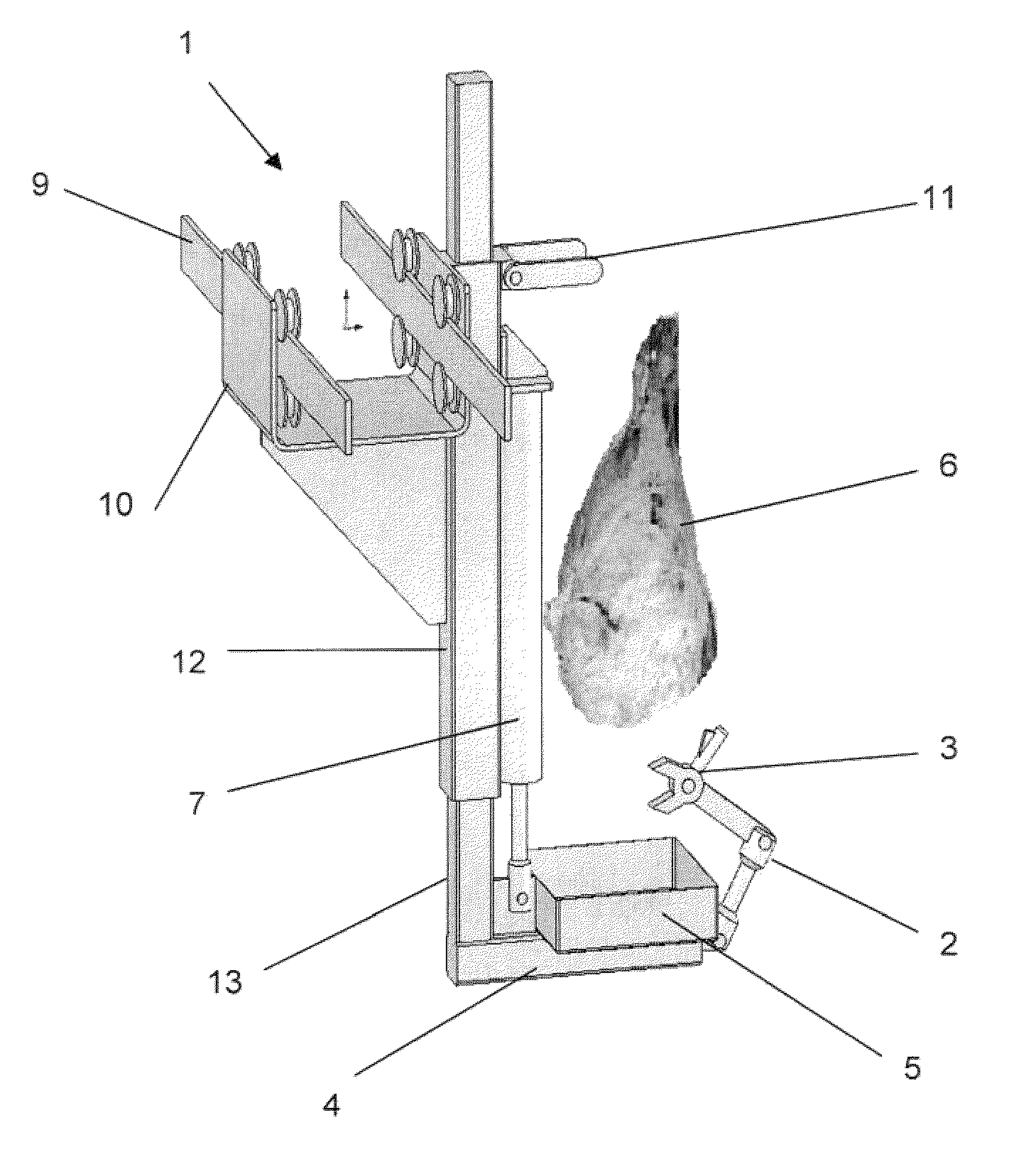

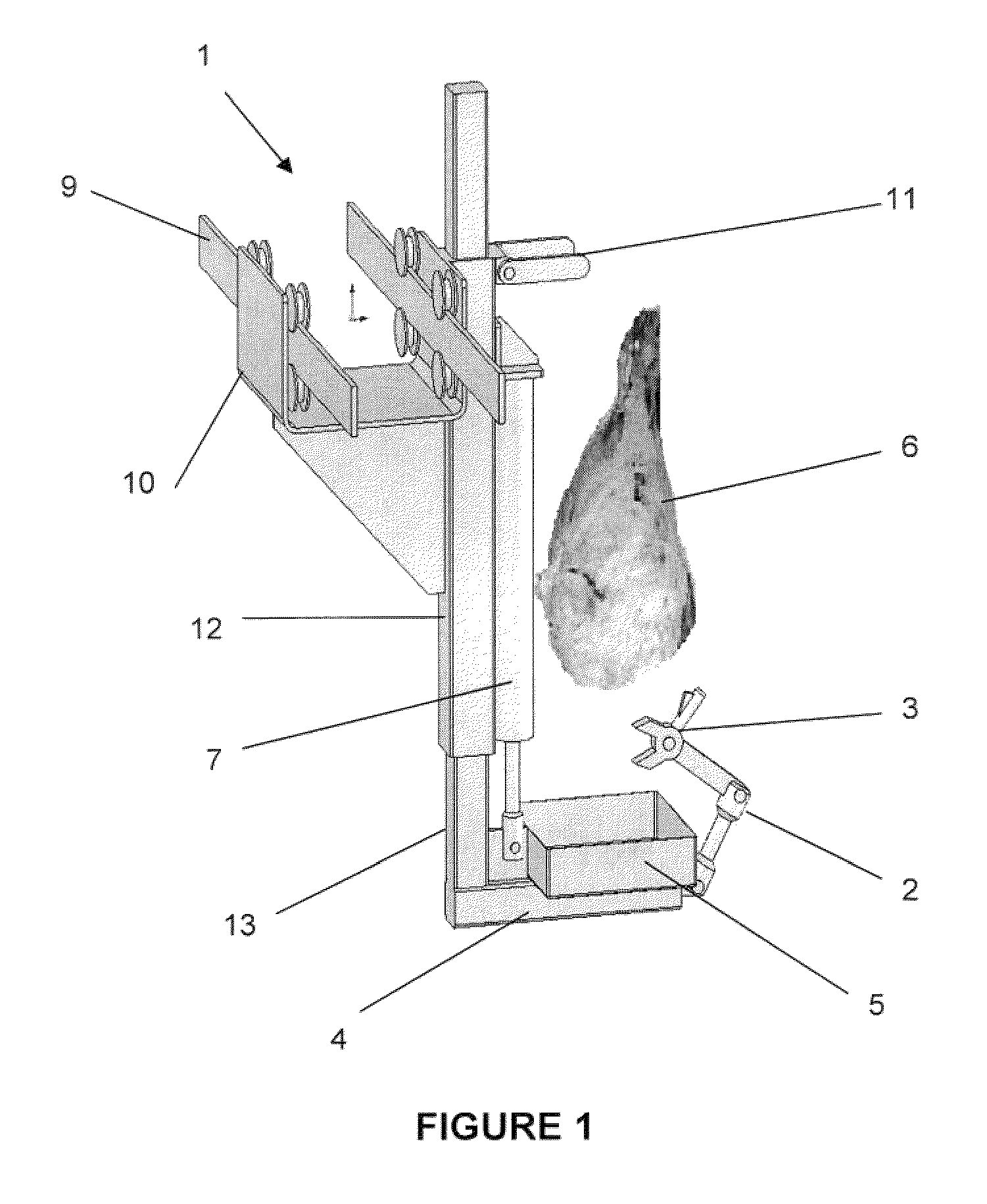

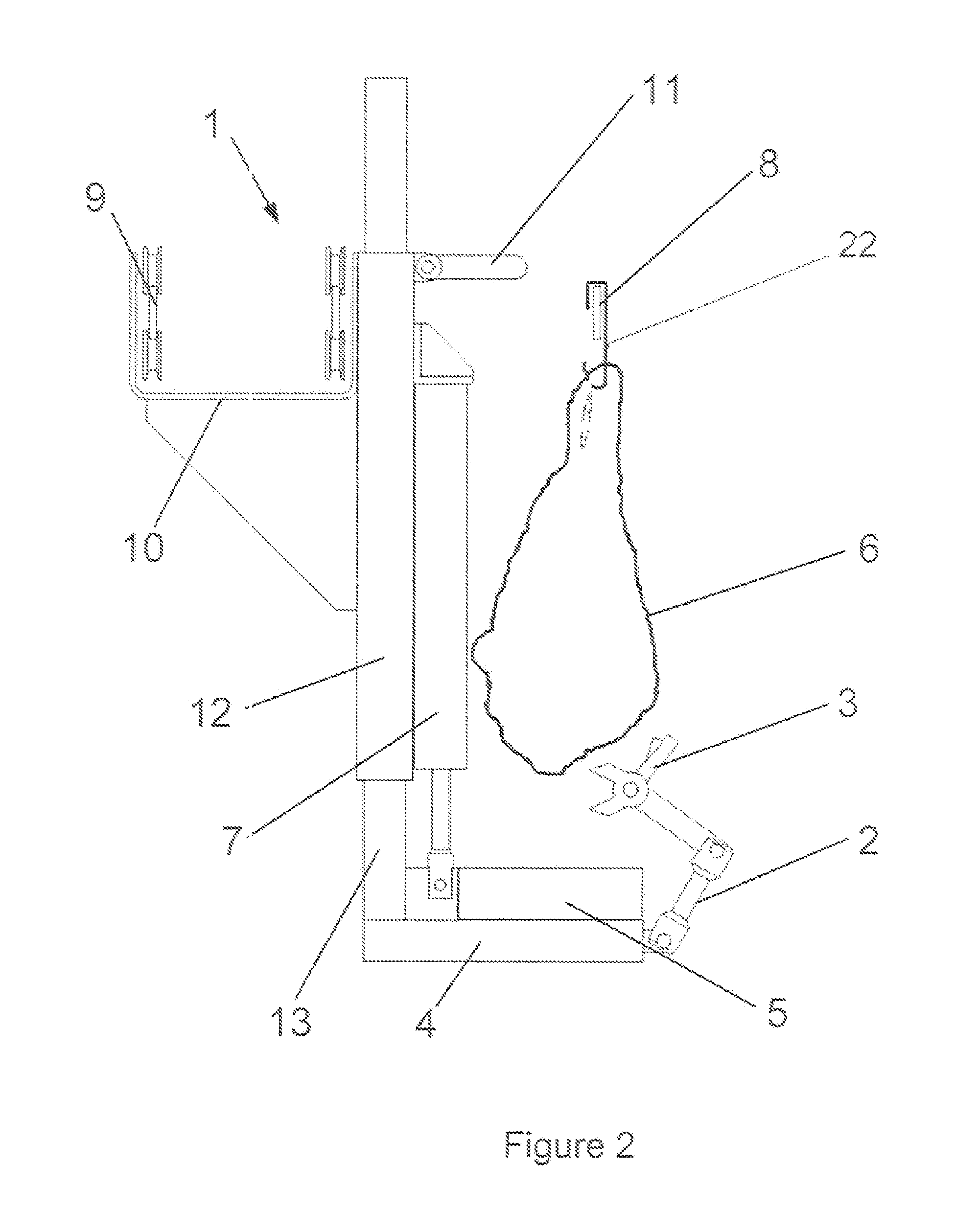

Puller for use in animal carcass boning or cutting

ActiveUS8257154B2Easy to moveLittle strengthMeat holding apparatusMeat processing plantsEngineeringGrippers

An apparatus for pulling a section of an animal carcass from the carcass wherein the carcass is held using means for holding. The apparatus includes means for anchoring to the section of the carcass, and means for forcibly separating the means for anchoring from the means for holding, preferably in a substantially vertical downwards direction, and thereby remove the section from the carcass. According to preferred embodiments, the means for anchoring may be a hook or a gripper which clamps to the section of the carcass. A system including the apparatus and a corresponding method are also provided.

Owner:ROBOTIC TECH

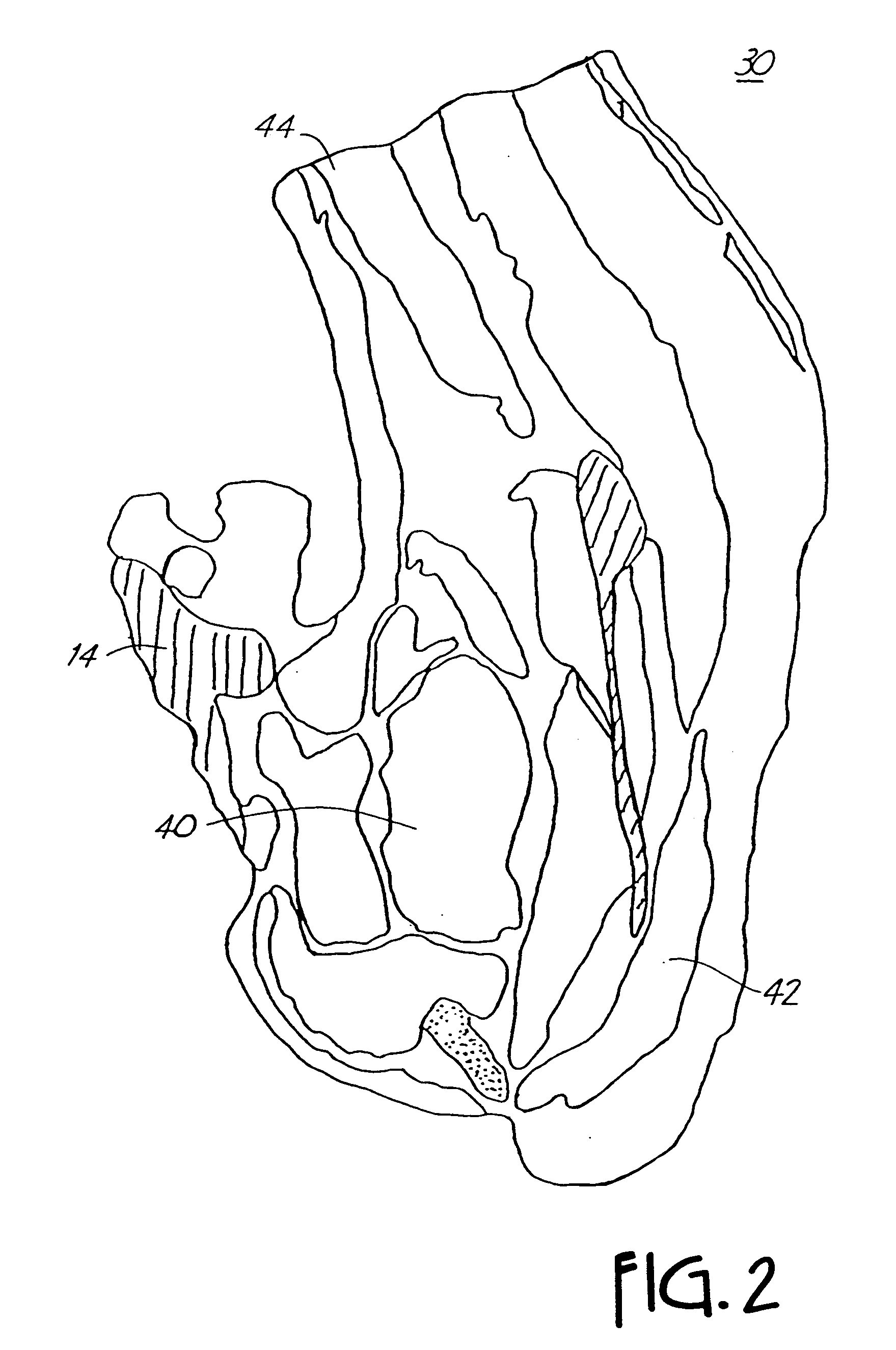

Process for making a boneless pork back rib product

Owner:GERALD J NAEHRING

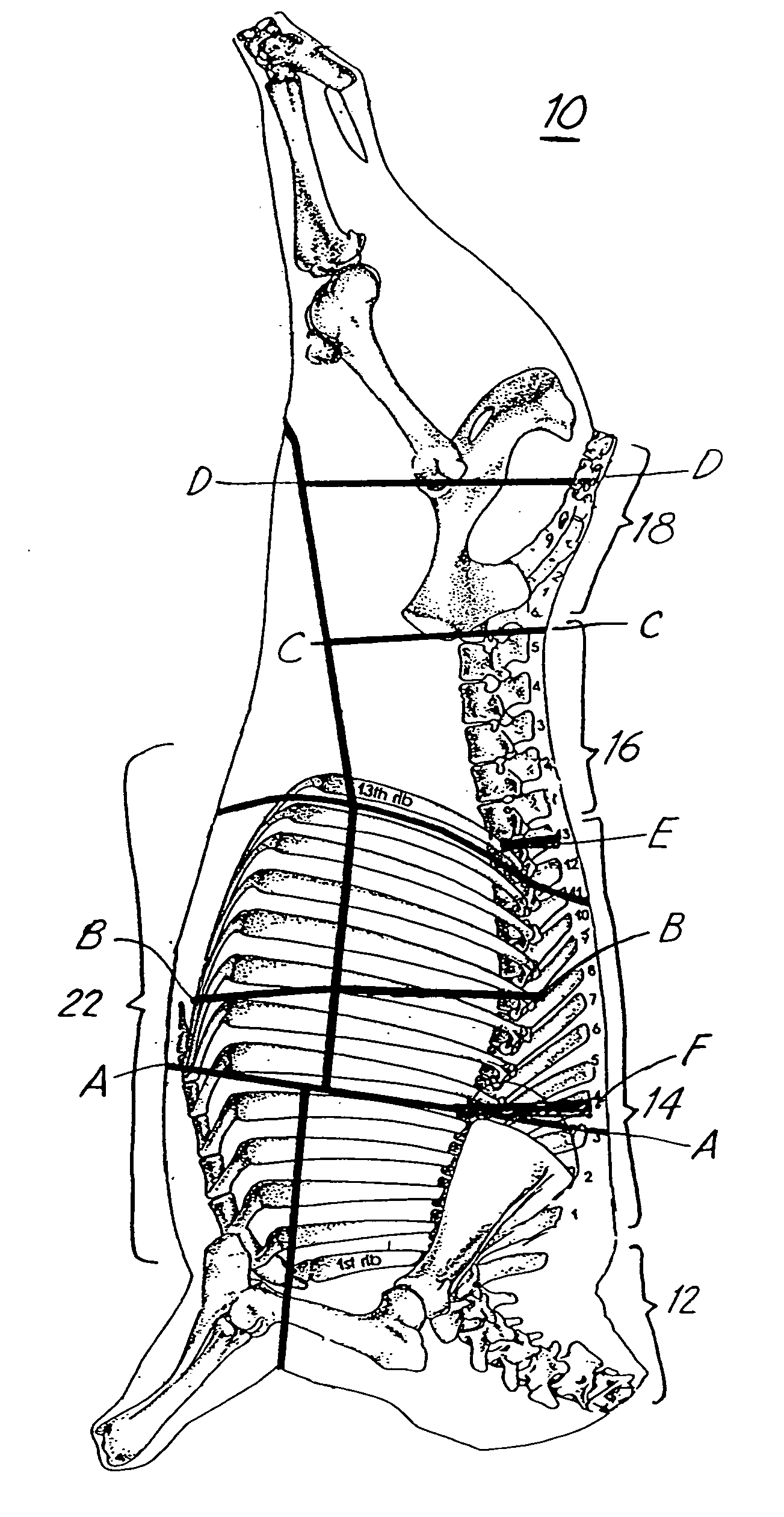

Separation of the spinal column from a carcass middle part

ActiveUS8915773B2Quantity minimizationAccurate cutting positionMeat processing plantsPoultry processingSpinal columnEngineering

Owner:HUMBOLDT

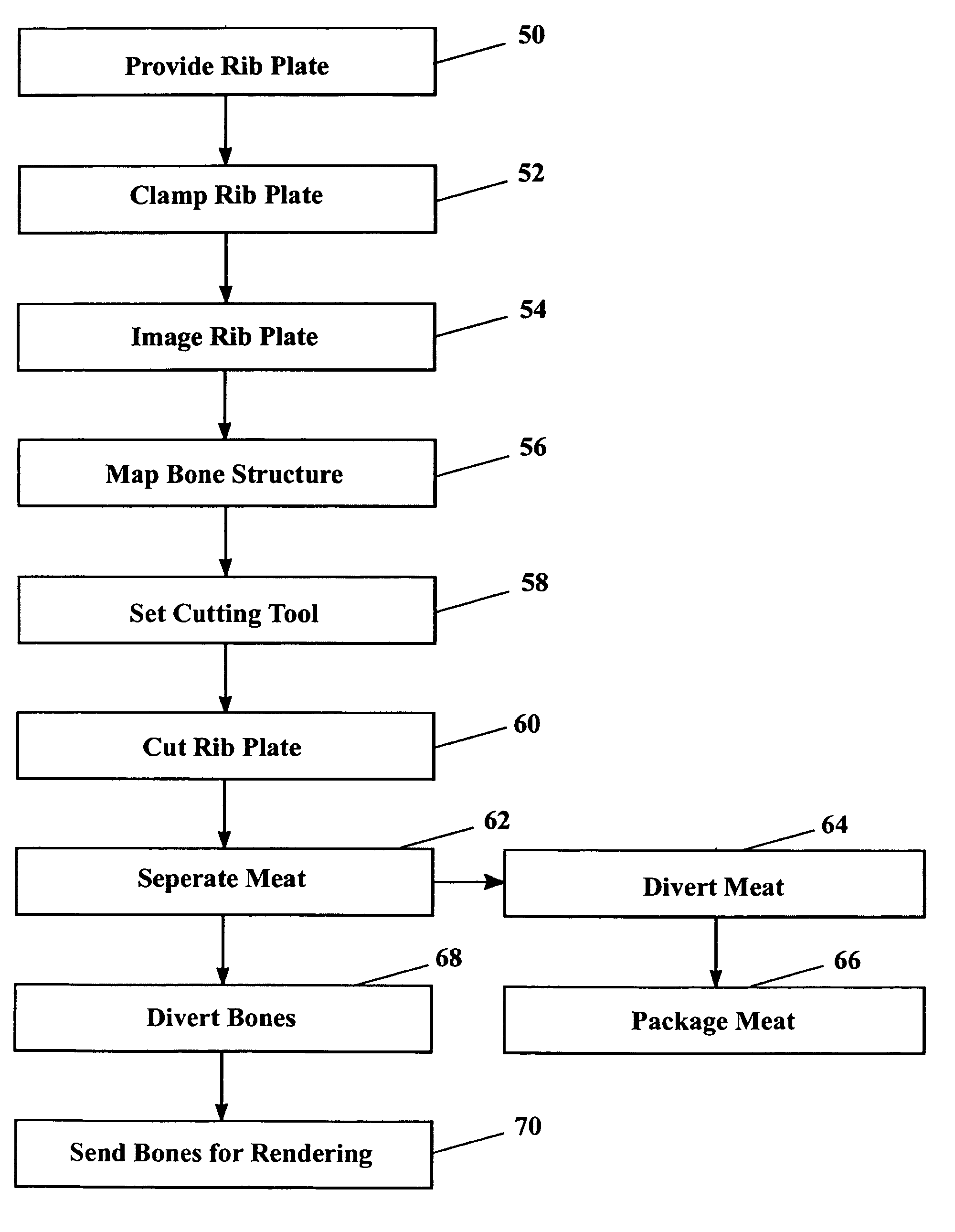

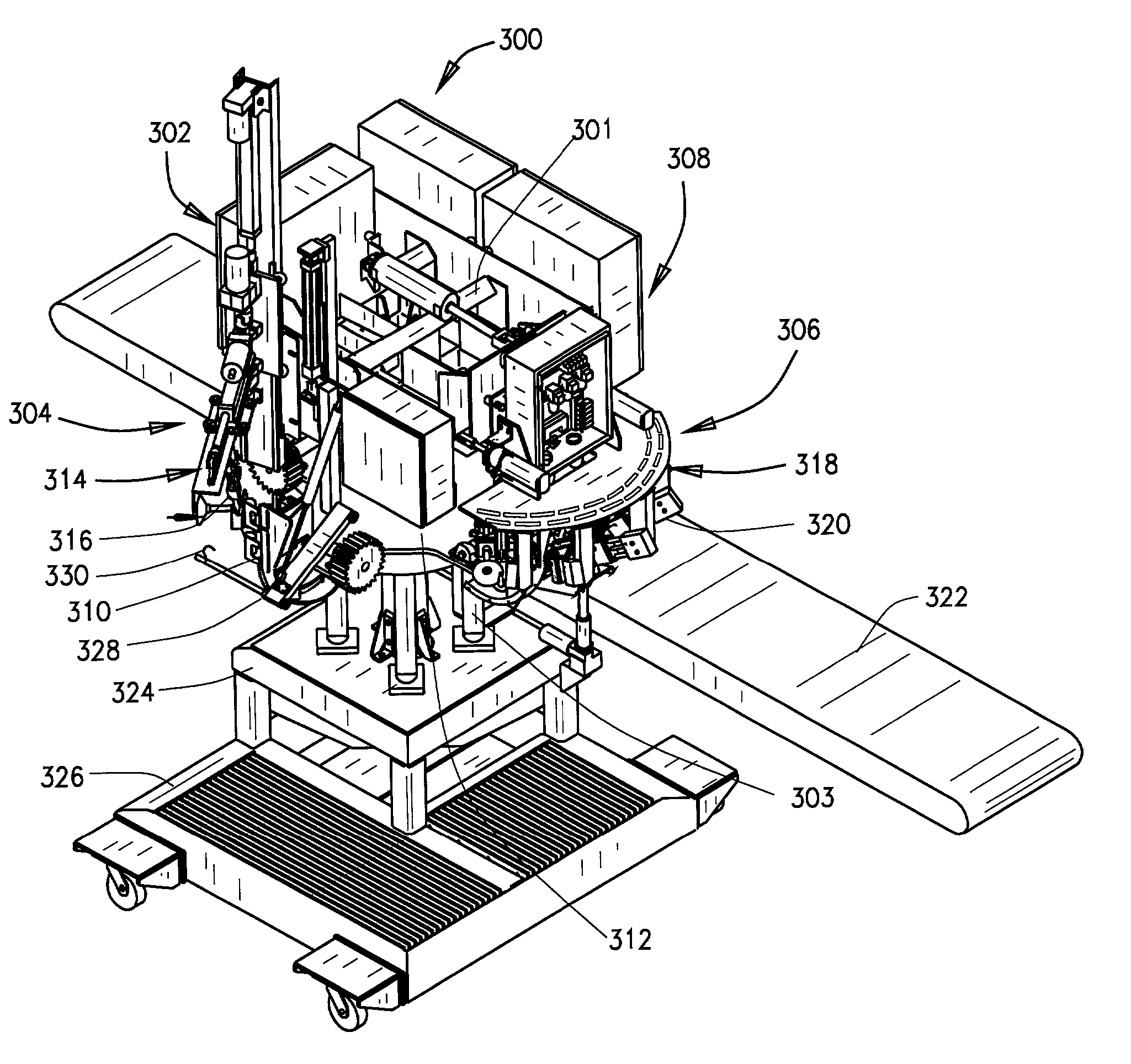

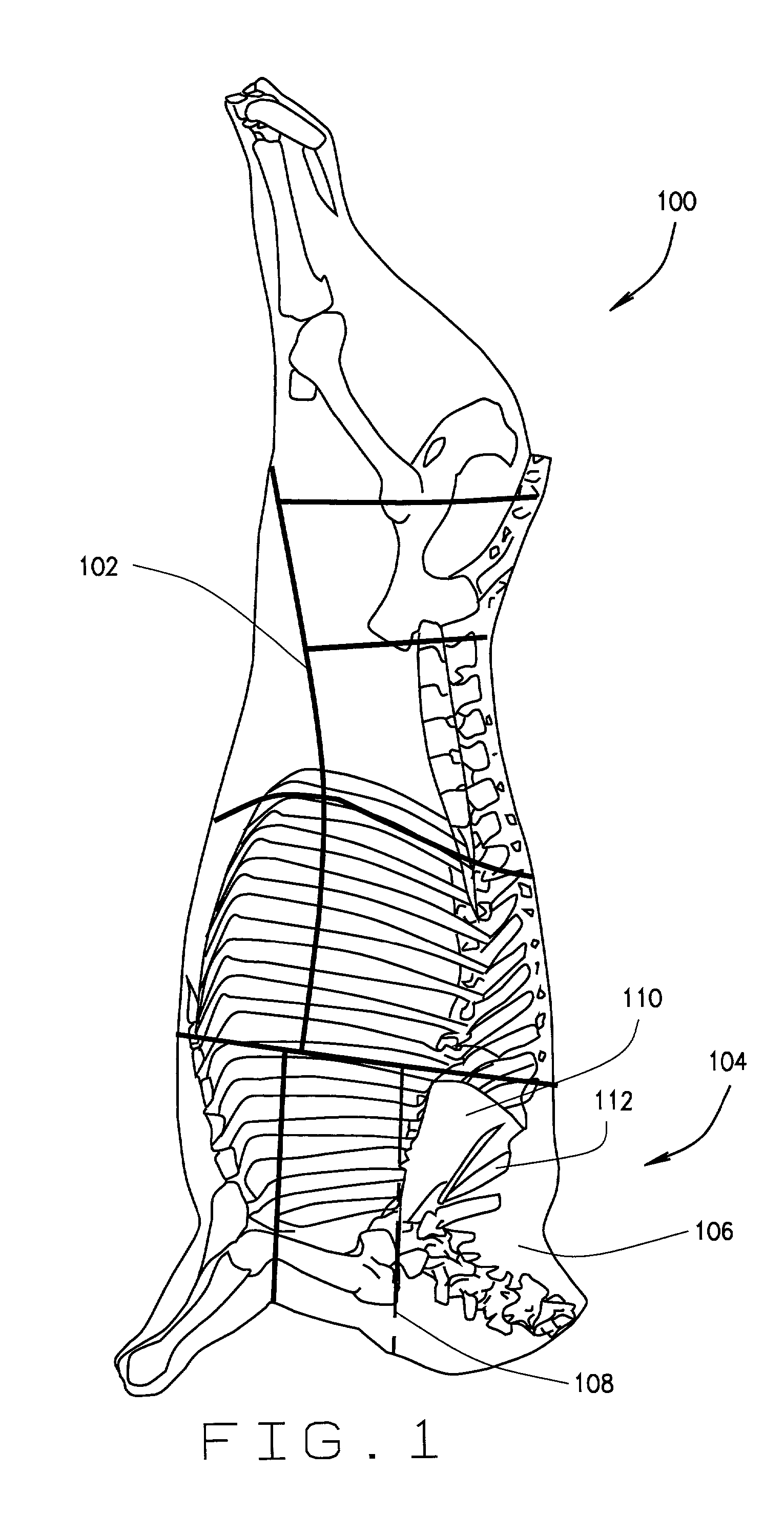

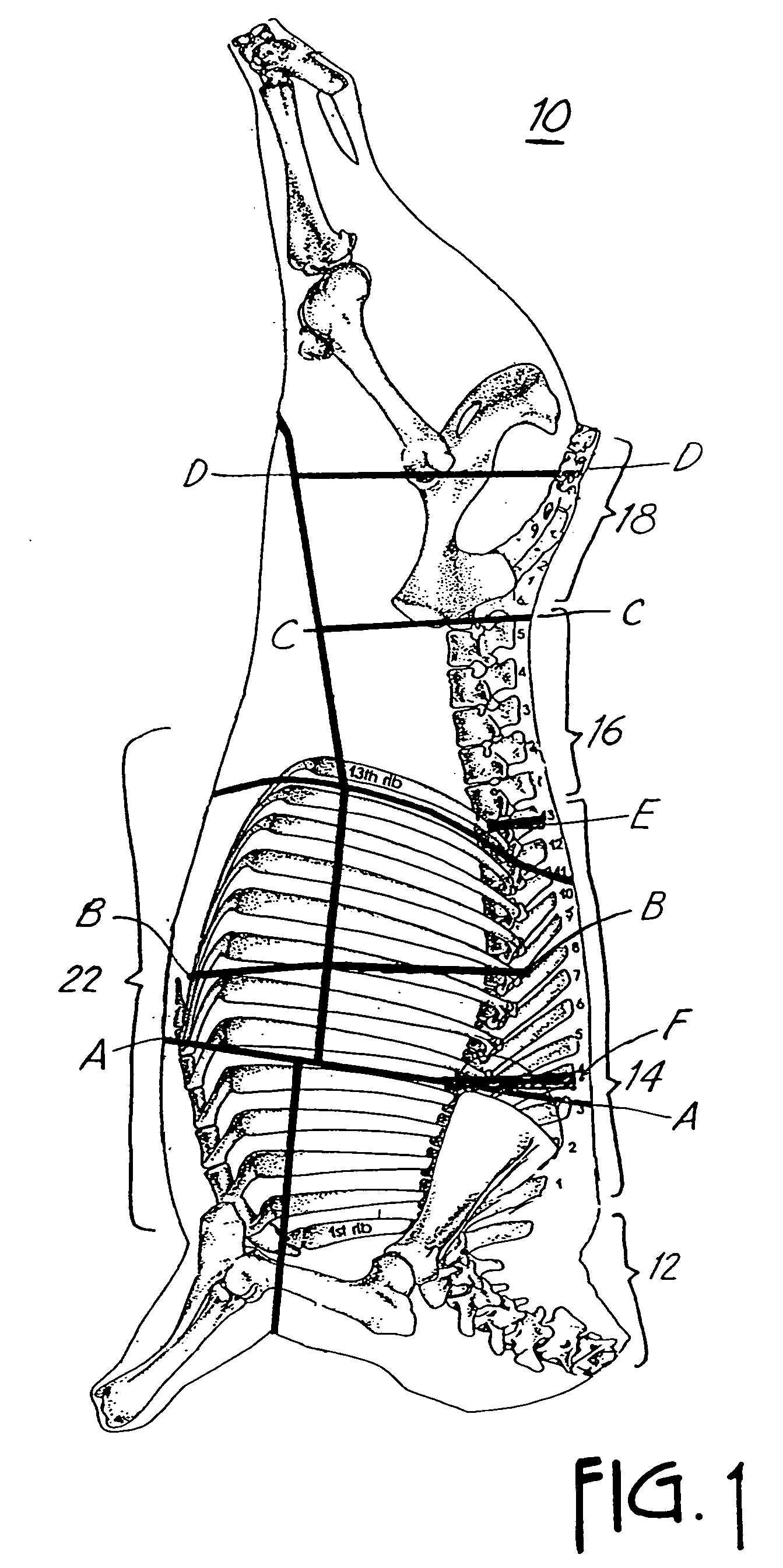

Meat fabrication system and method

ActiveUS20100130114A1Meat holding apparatusSampled-variable control systemsEngineeringMechanical engineering

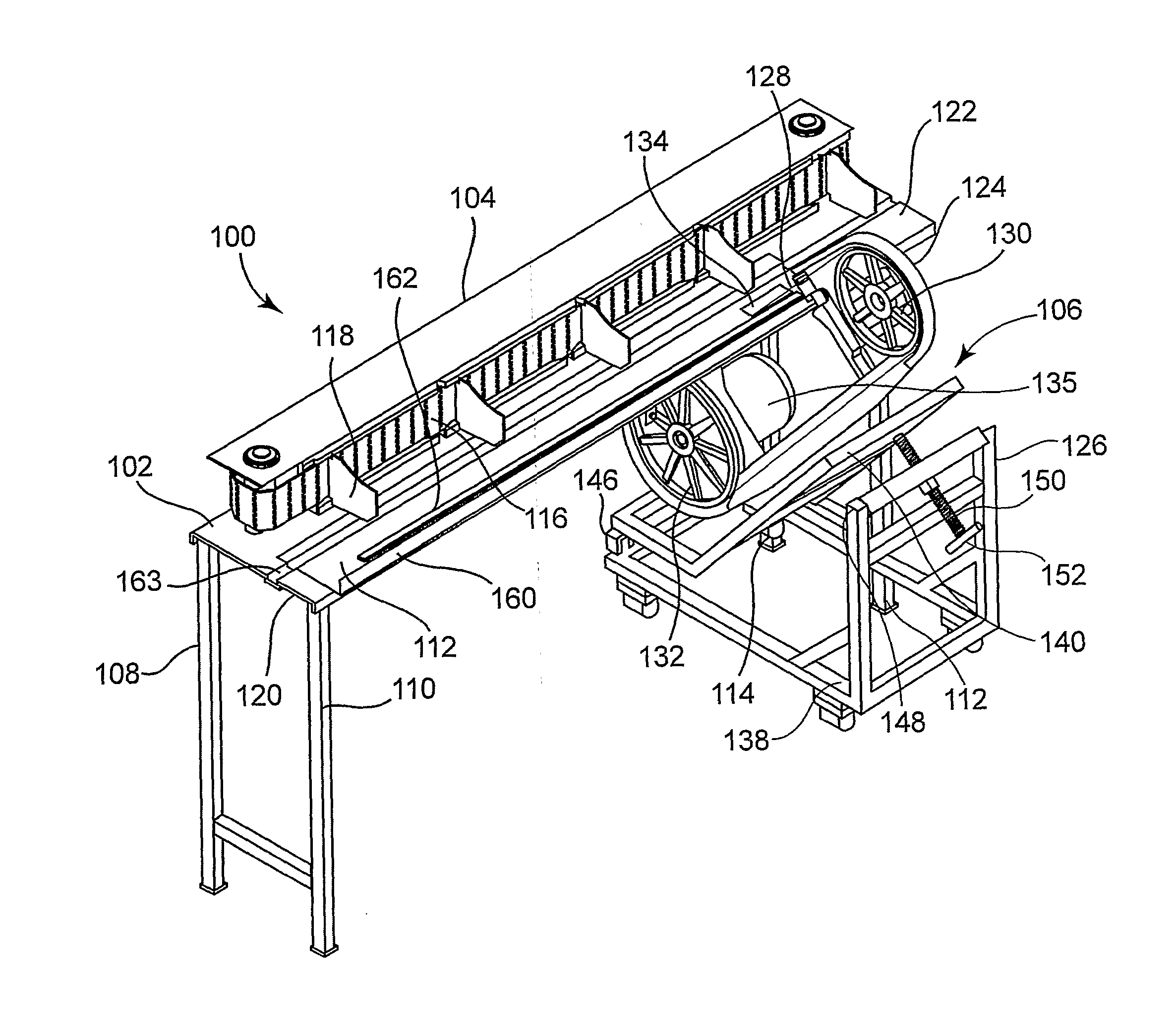

The present invention includes meat fabrication systems and methods. The system according to one embodiment includes a conveyor (104) for advancing meat cuts, a cutting assembly (106) defining a cutting path (136) that intersects the conveyor (104), and at least one guide (160, 162, 163) that orientates the meat cuts on the conveyor relative to the cutting path such that the chine bones of the meat cut are separated from the remaining portions of the meat cuts as the meat cuts are advanced through the cutting path (136) by the conveyor (104).

Owner:CARGILL INC

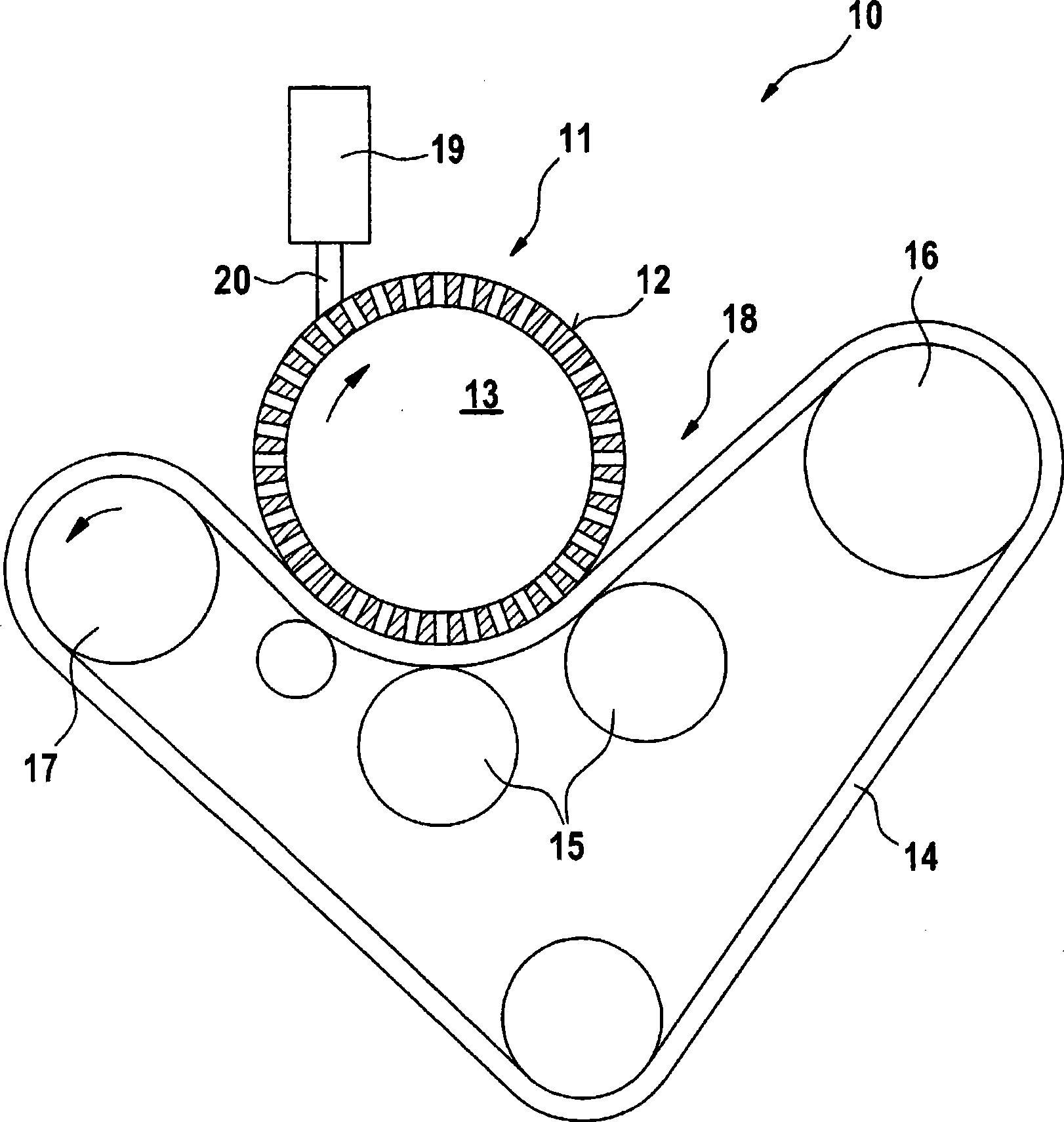

Apparatus and method for separating mixed materials of different flowability

ActiveCN101462373AQuick and easy to-and-fro movementReduce contact pressureMeat deboningPressesFunctional connectivityEngineering

The invention concerns an apparatus for separating mixed materials of different flowability. The apparatus comprises a housing having side walls, a rotationally driven hollow drum with perforated peripheral surface, an endless compression belt which can be pressed against the peripheral surface from the outside, wrapping round part of the circumference of the hollow drum, a product feed wedge, a supporting apparatus having at least one supporting element which is arranged on the side of the compression belt opposite the hollow drum, and a stripping means for stripping the compressed material from the hollow drum. The stripping means can be actively controlled such that during the separating process the stripping means is movable back and forth between a working position, for producing a functional connection with the peripheral surface of the hollow drum in the direction of the hollow drum, and a standby position for obtaining a distance between stripping means and hollow drum. The invention also concerns a corresponding method.

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

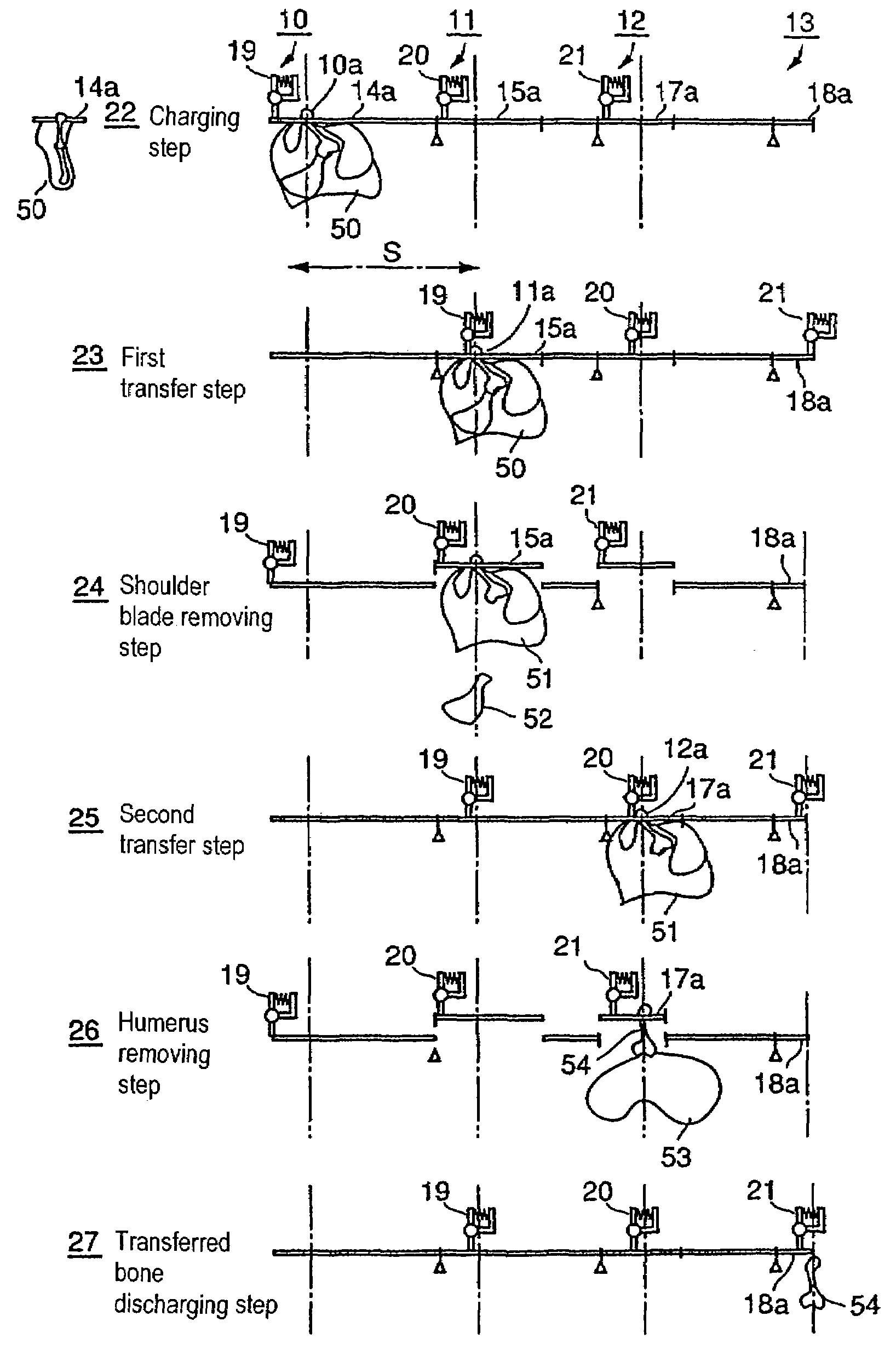

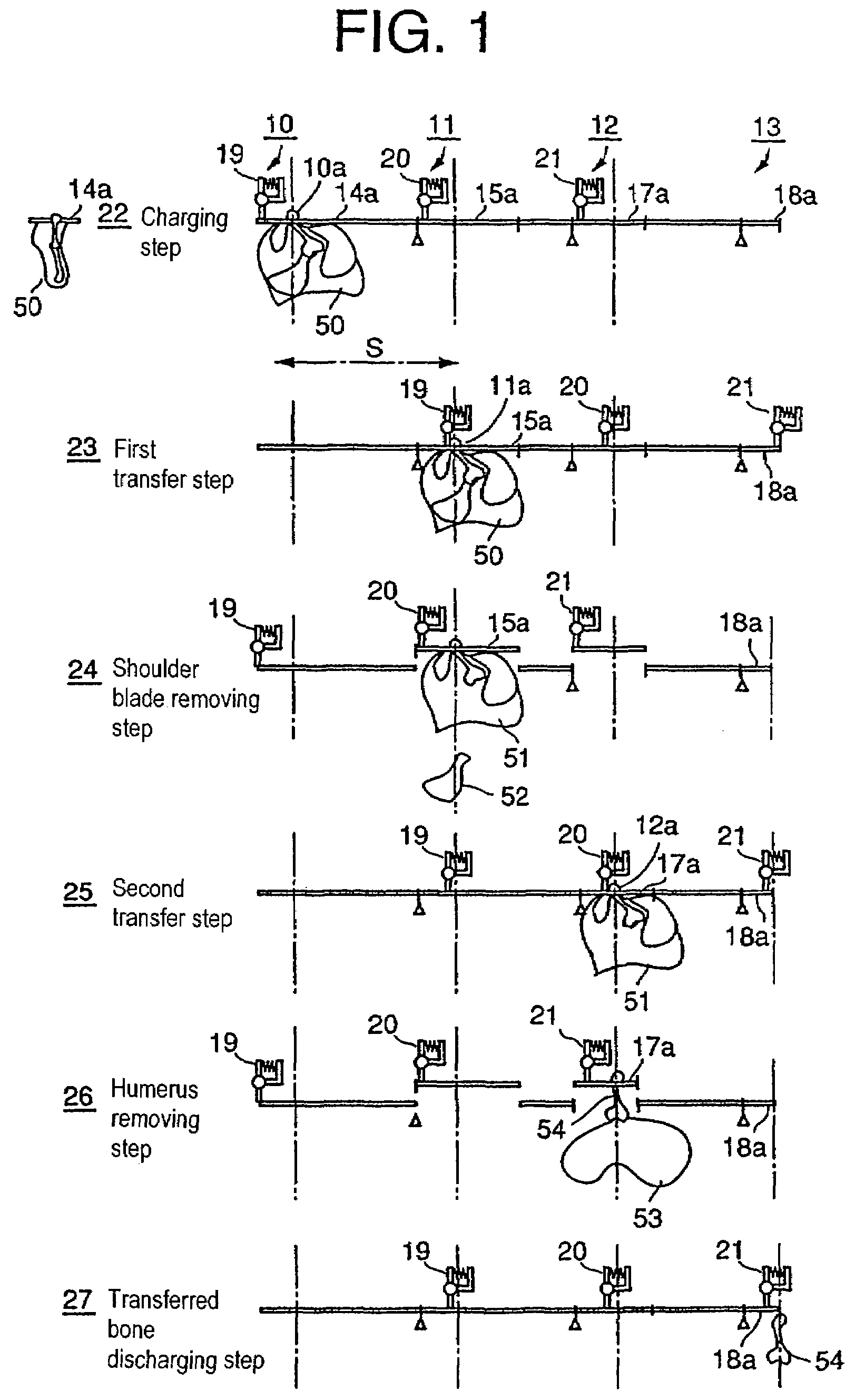

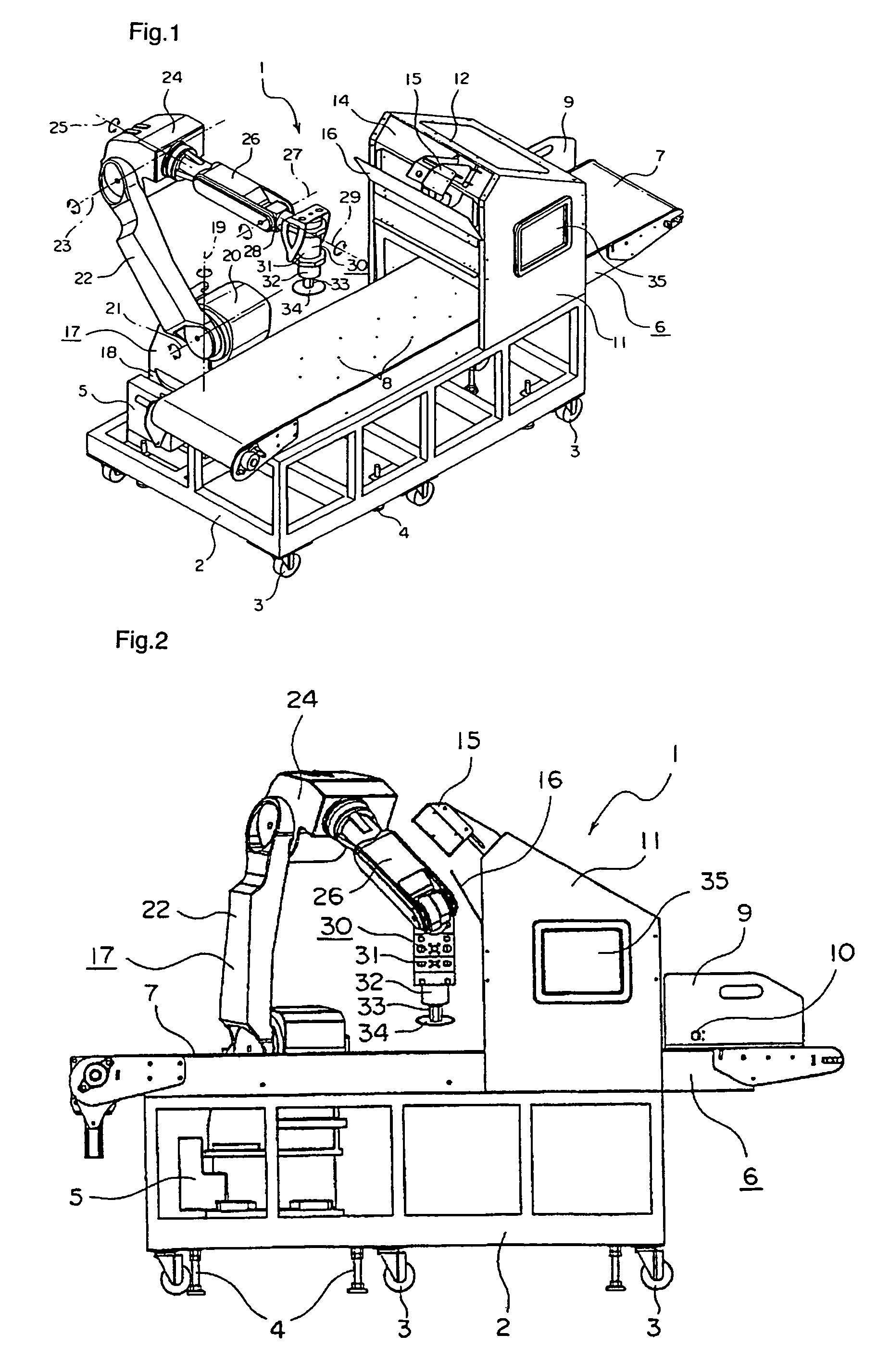

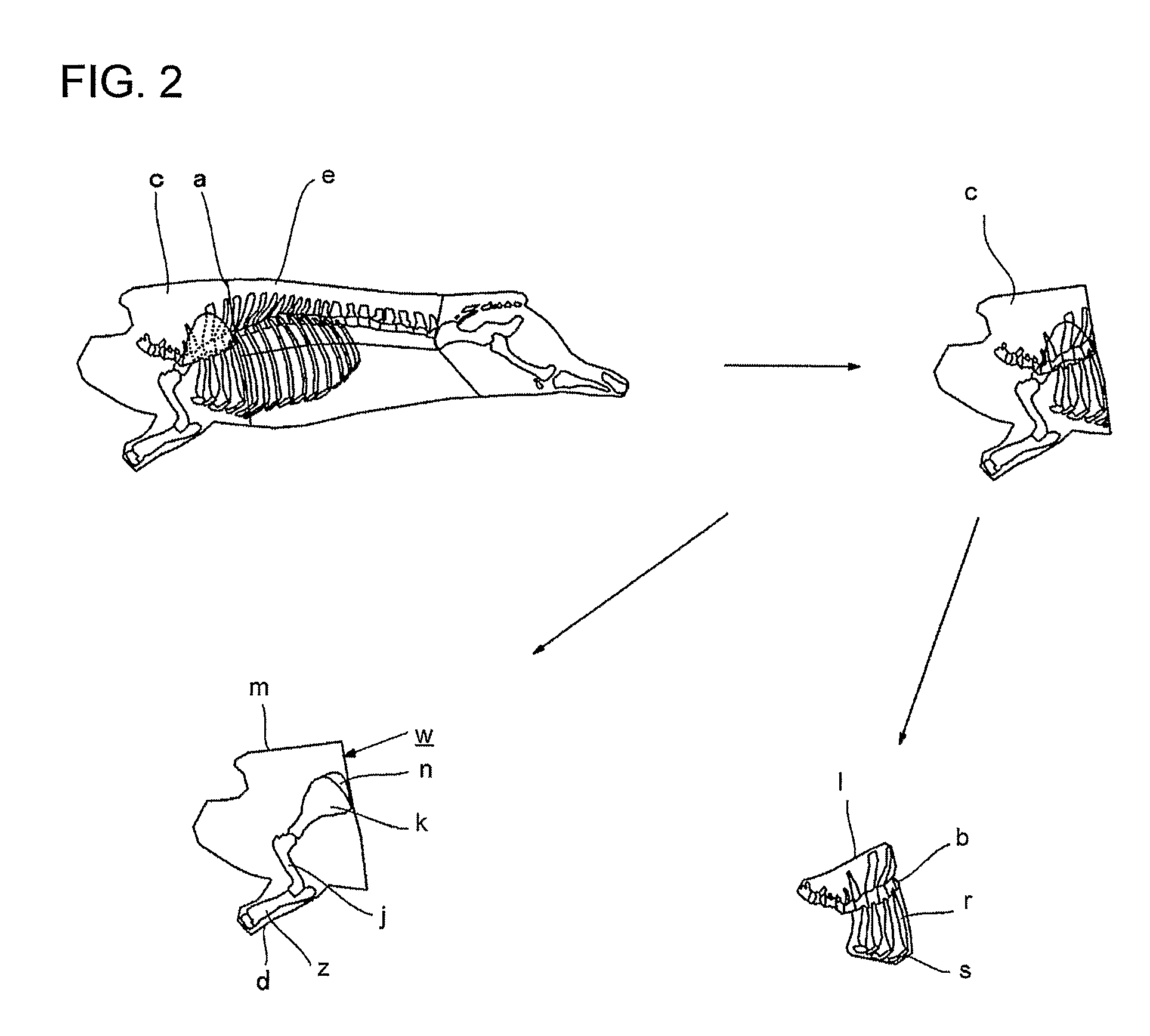

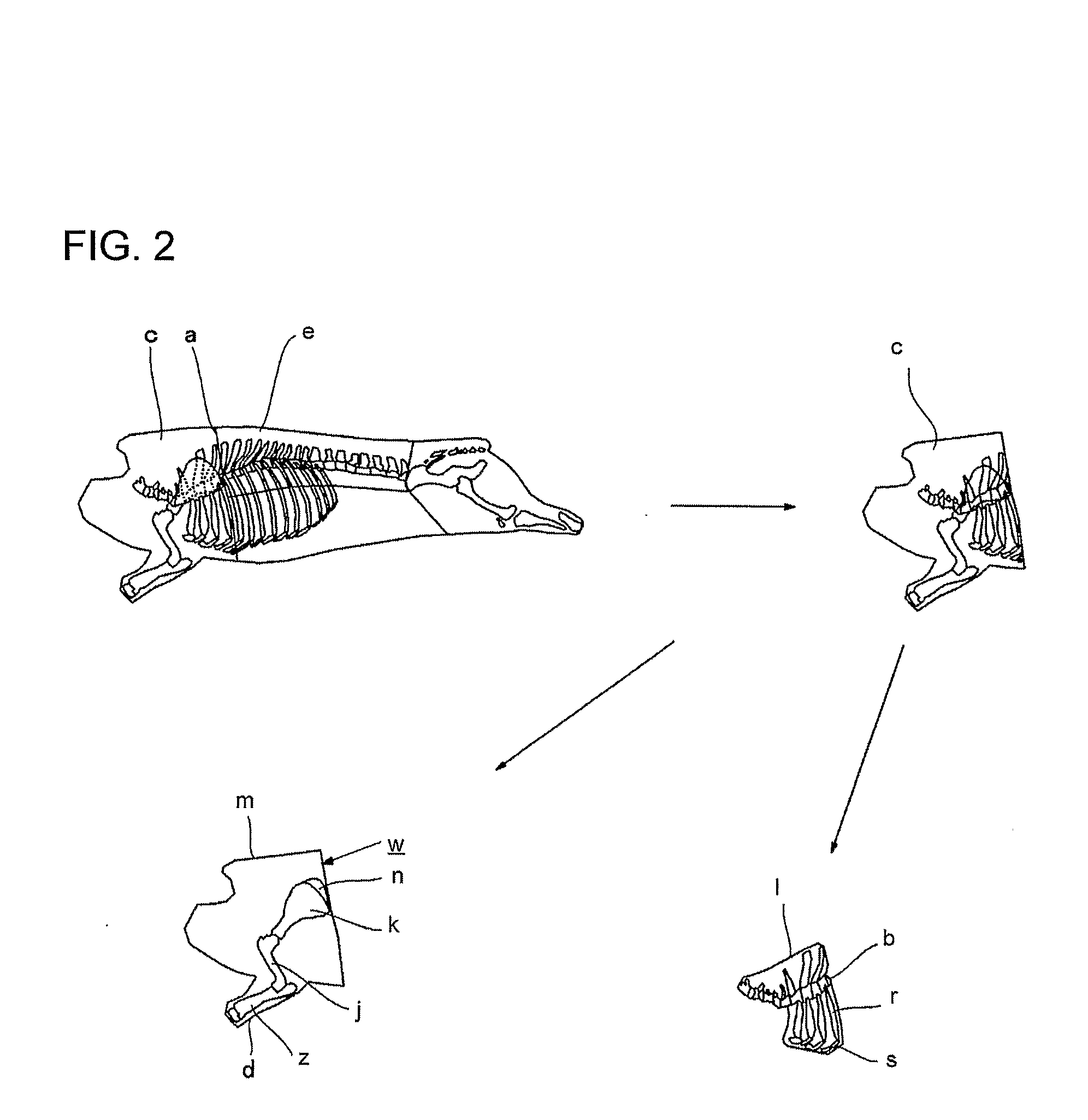

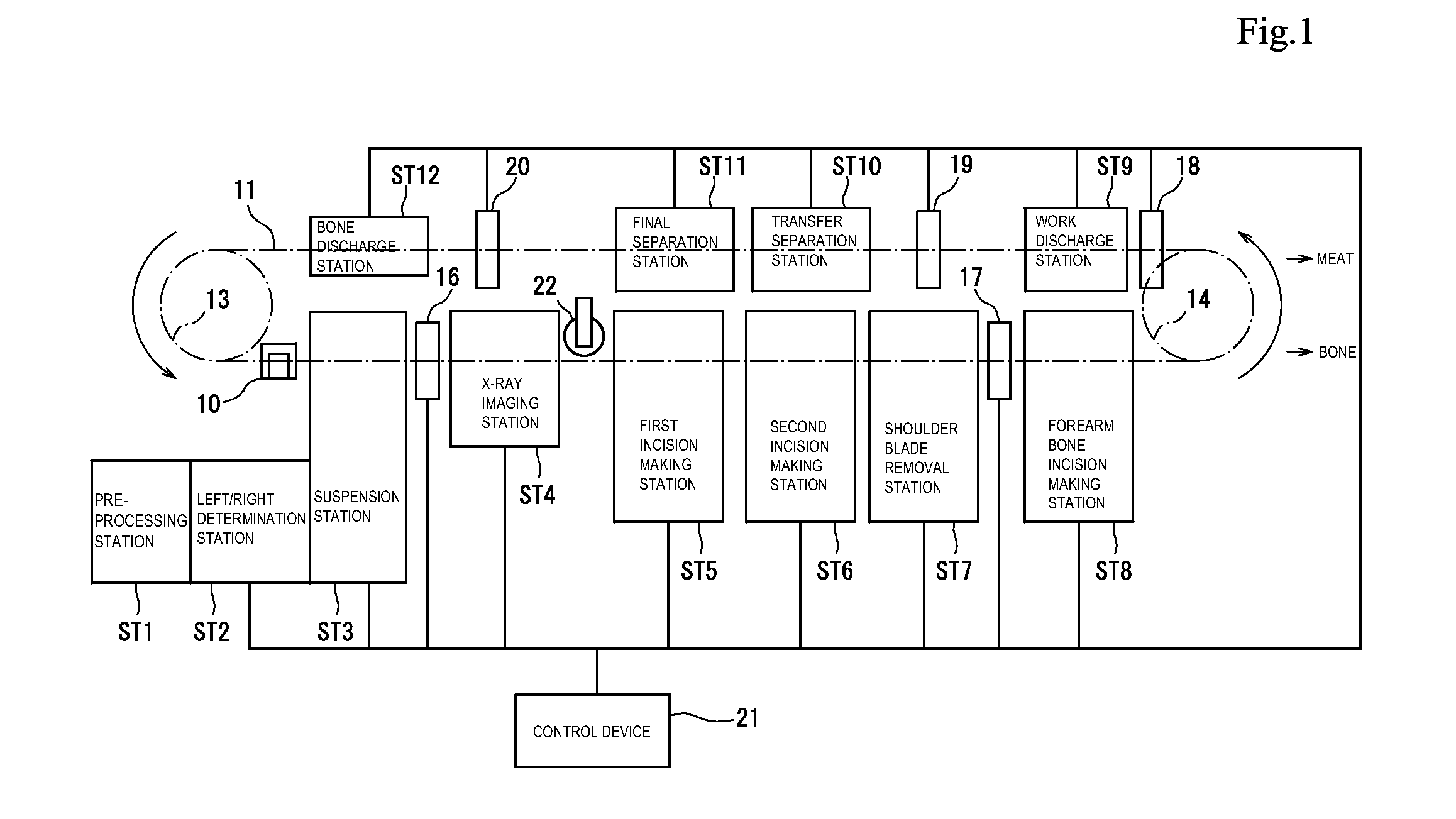

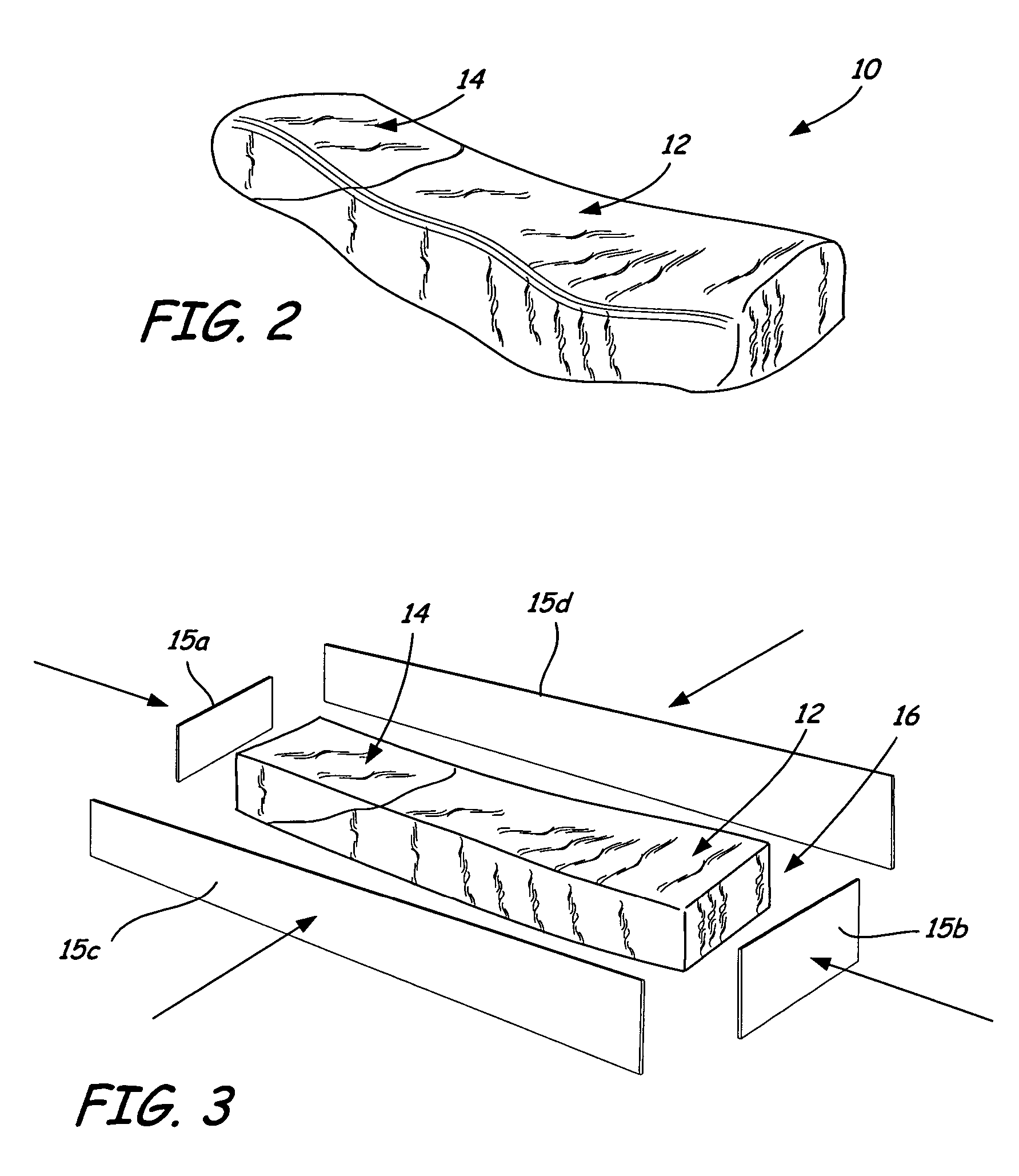

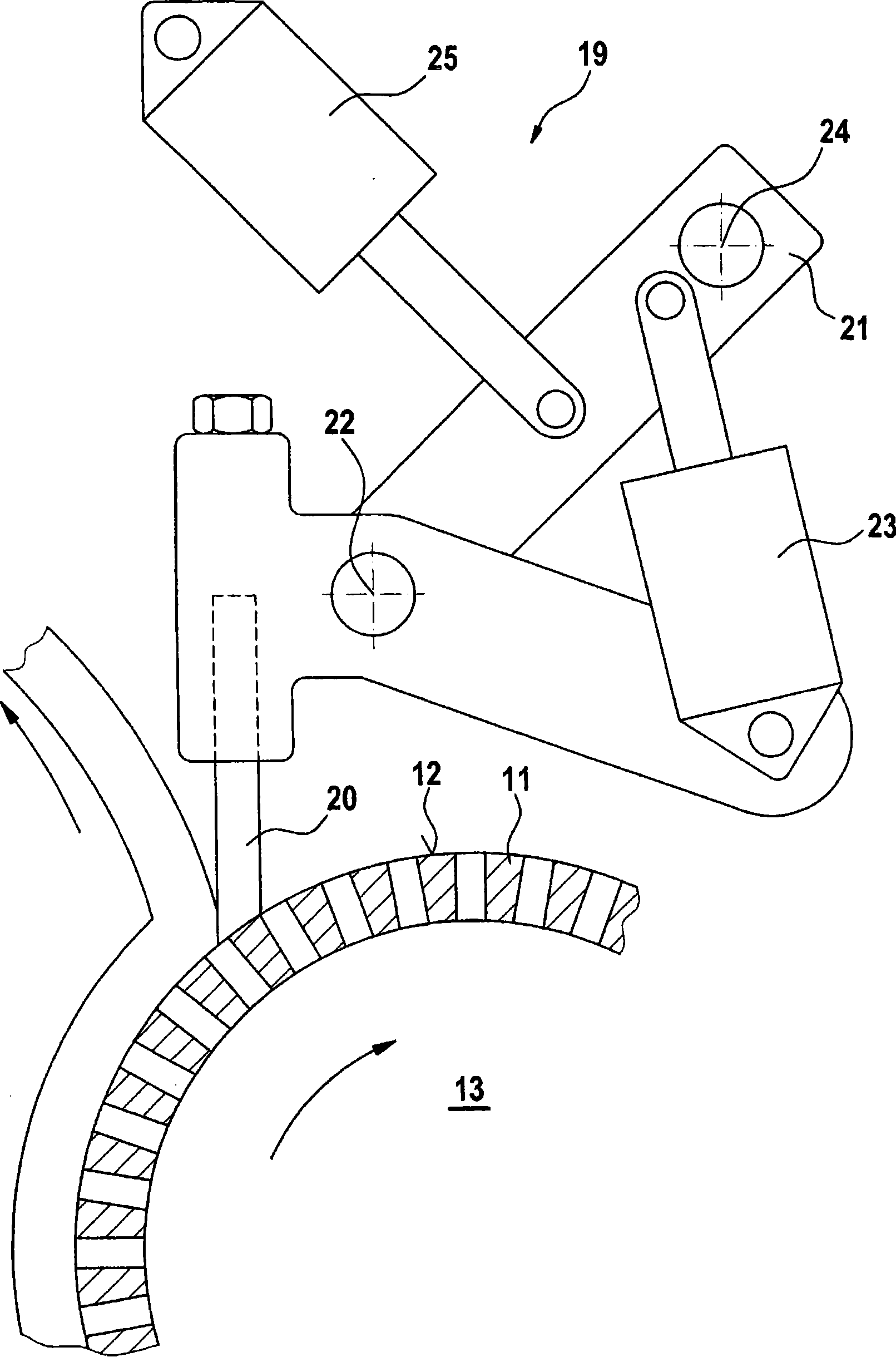

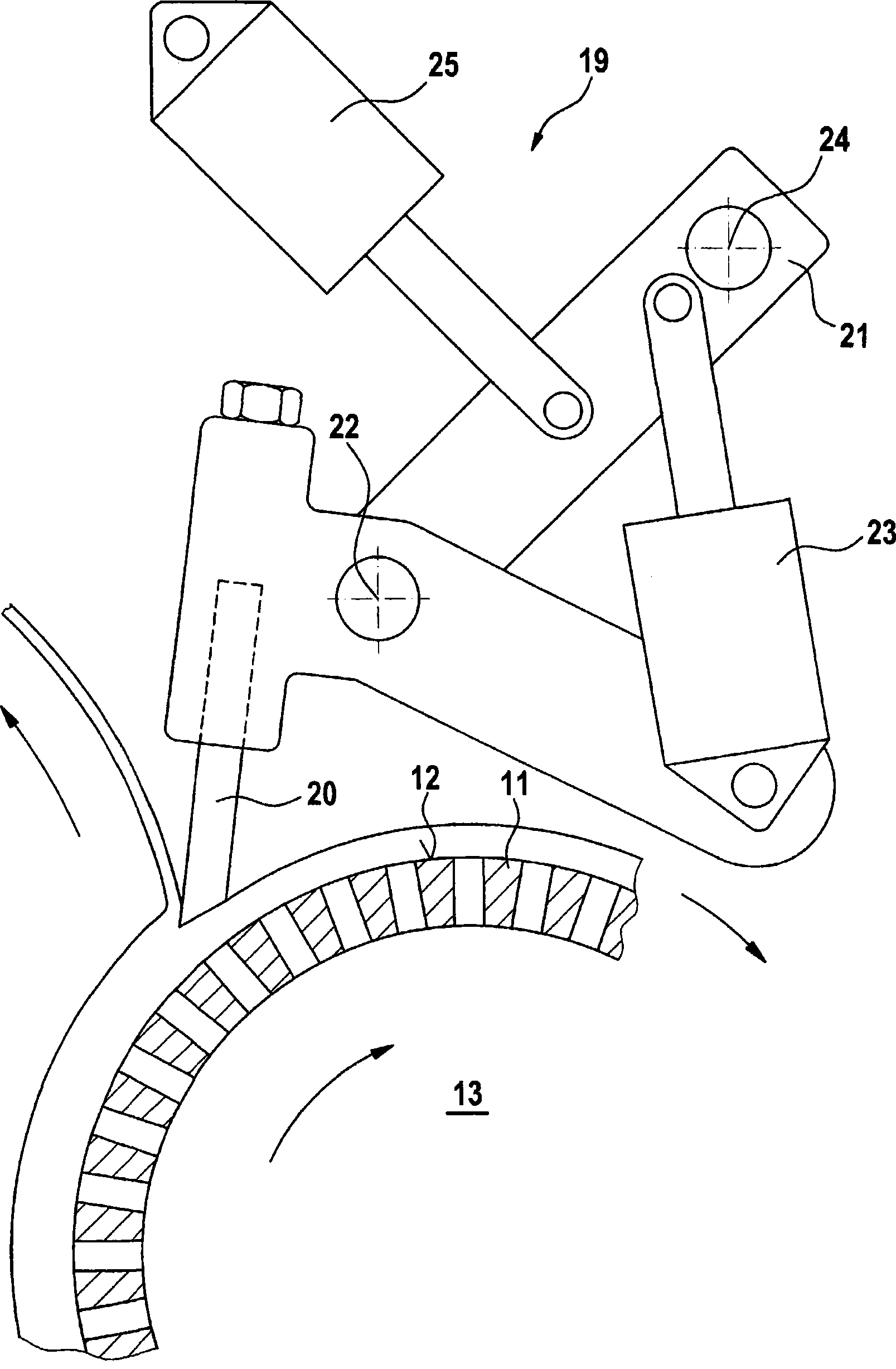

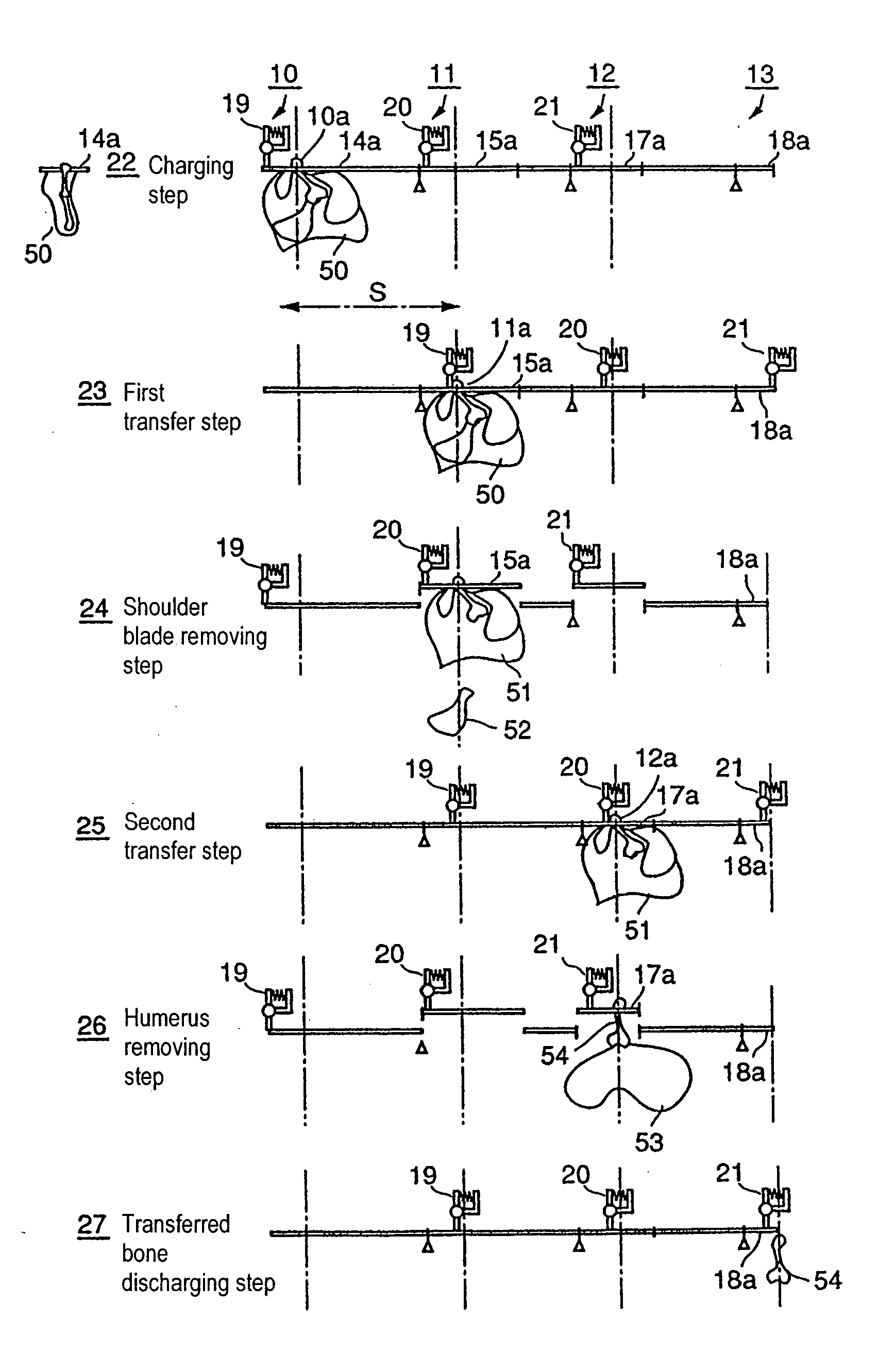

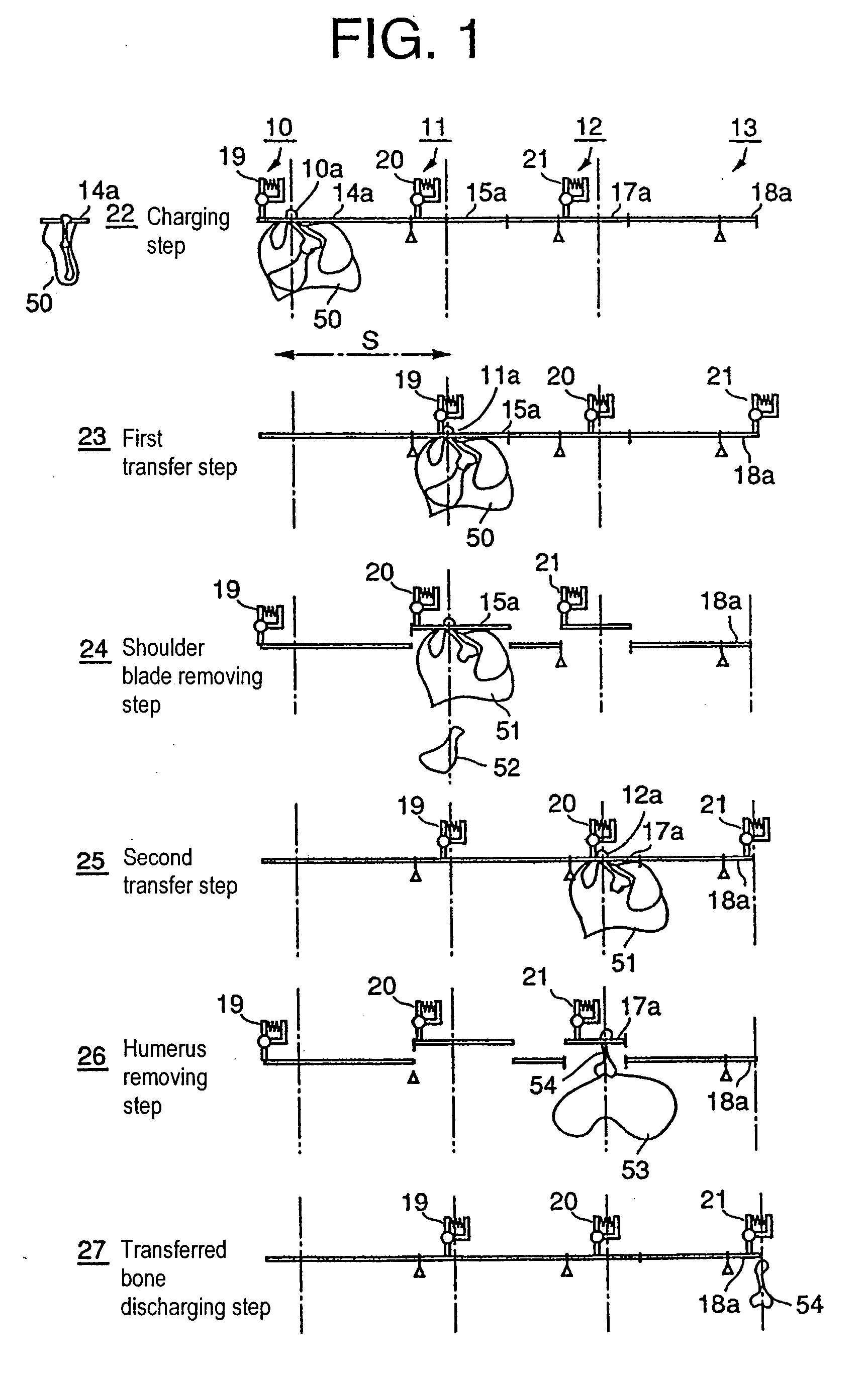

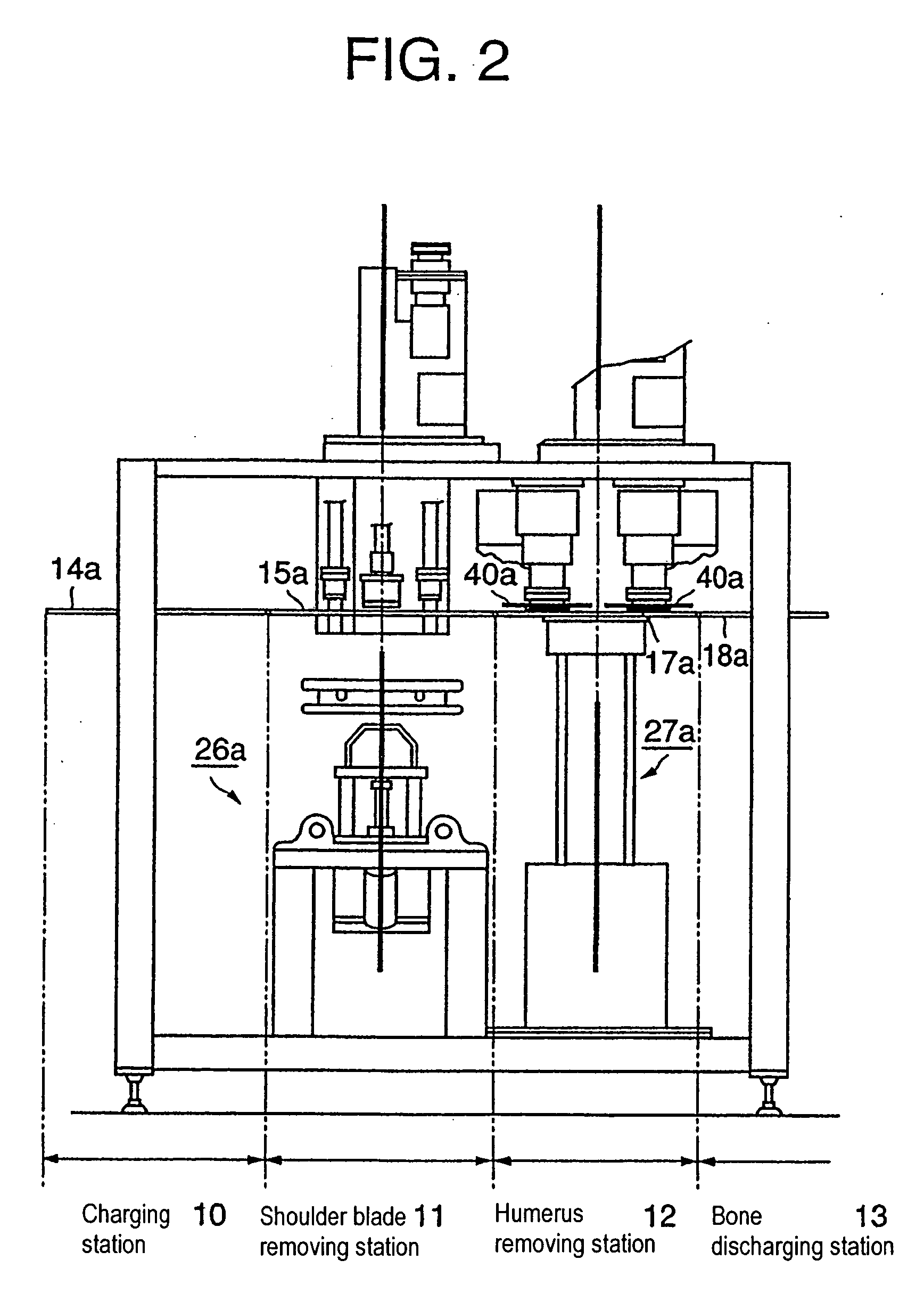

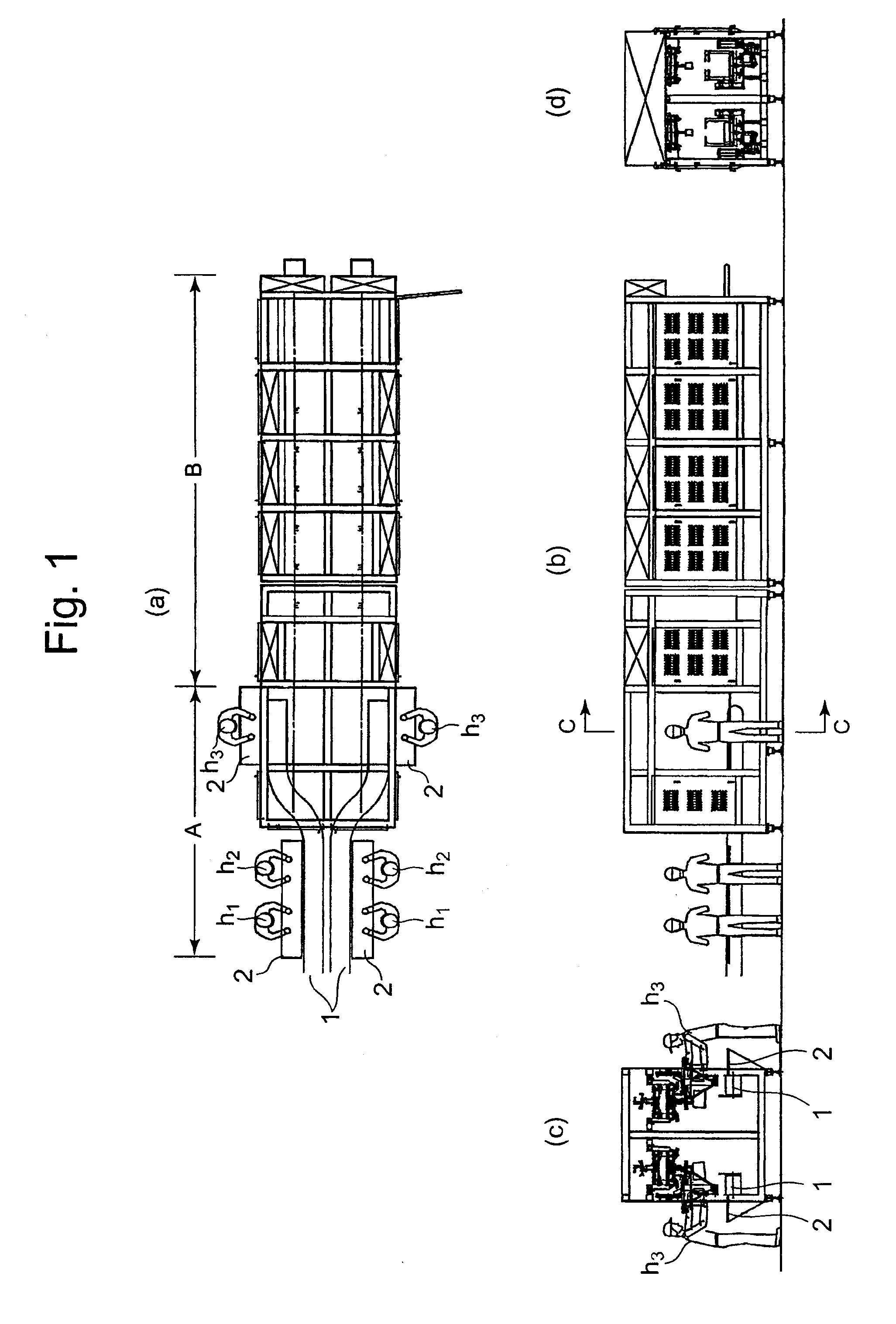

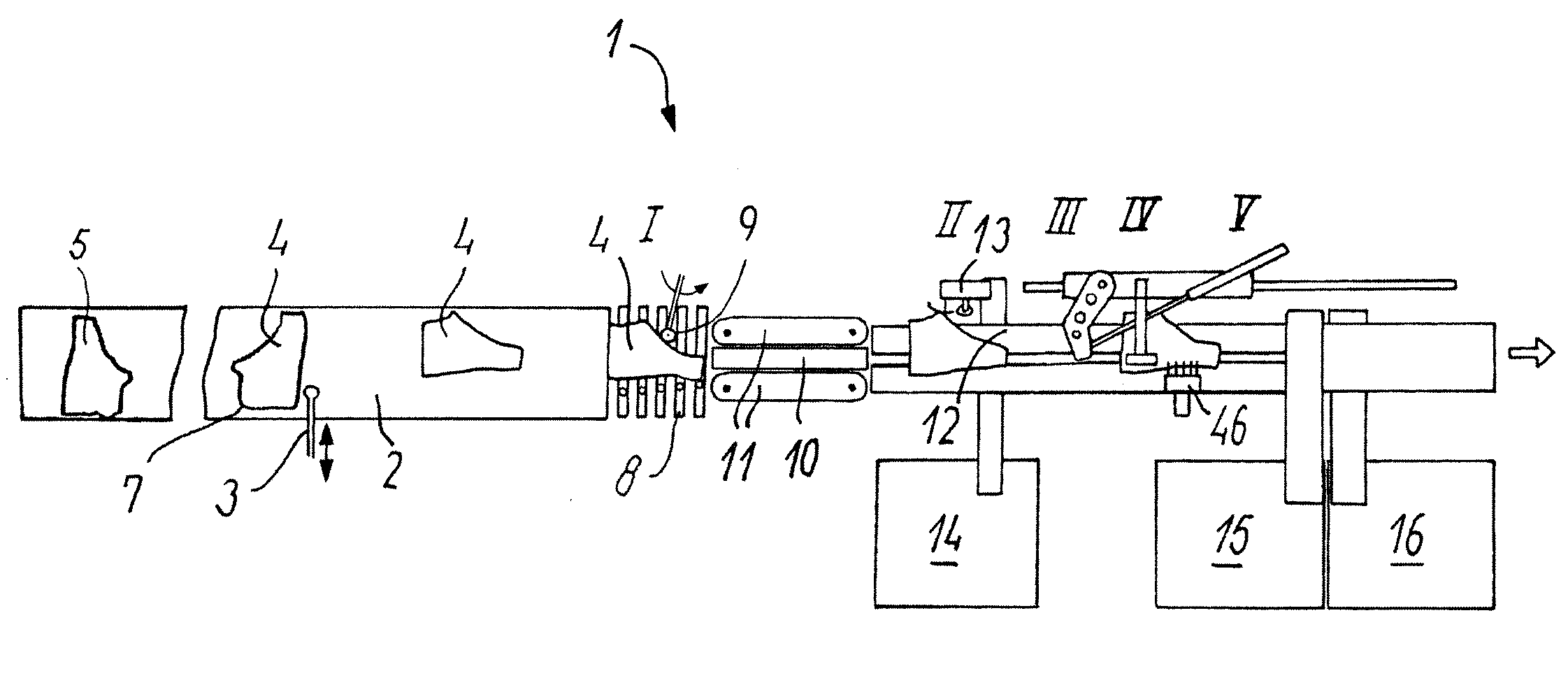

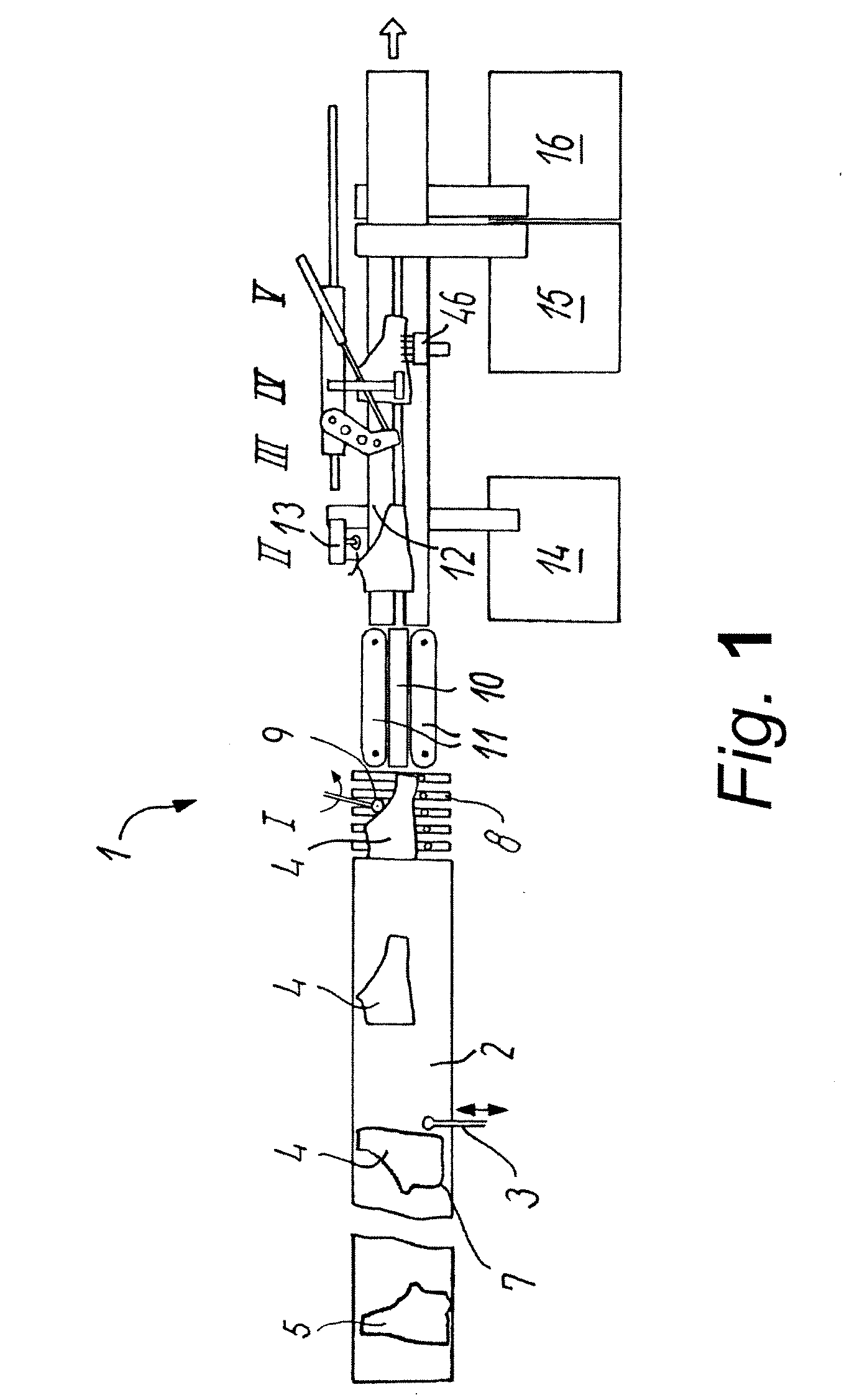

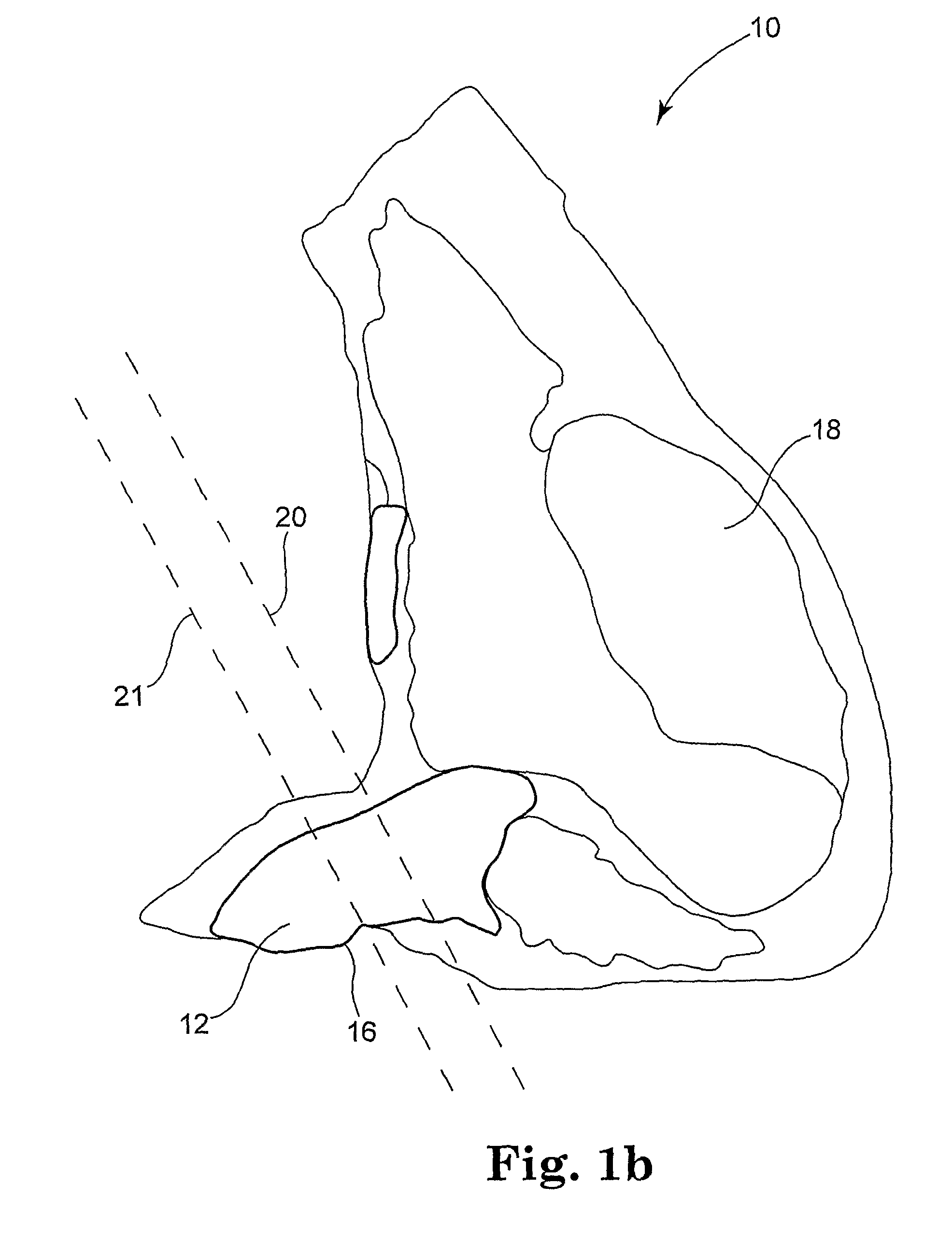

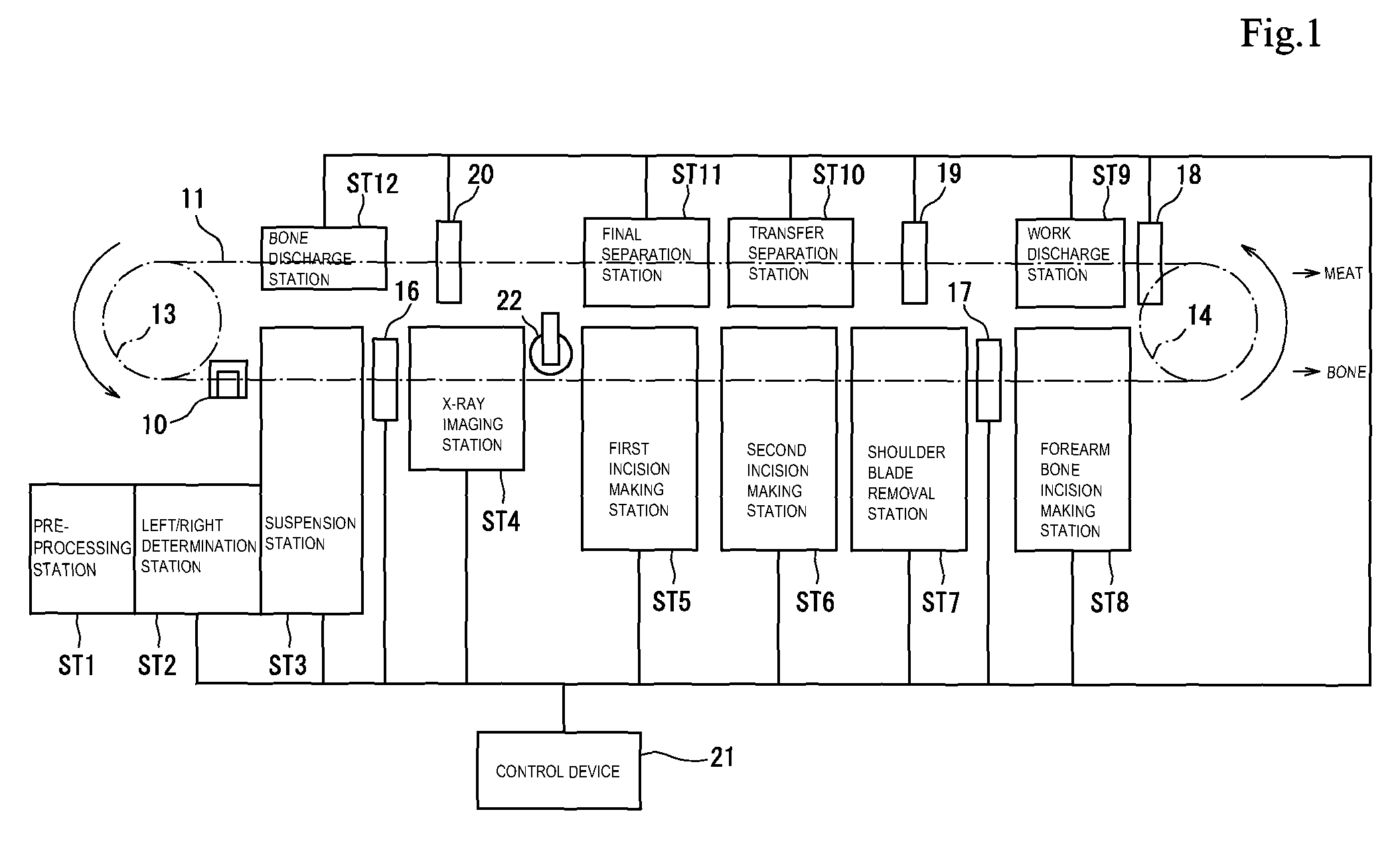

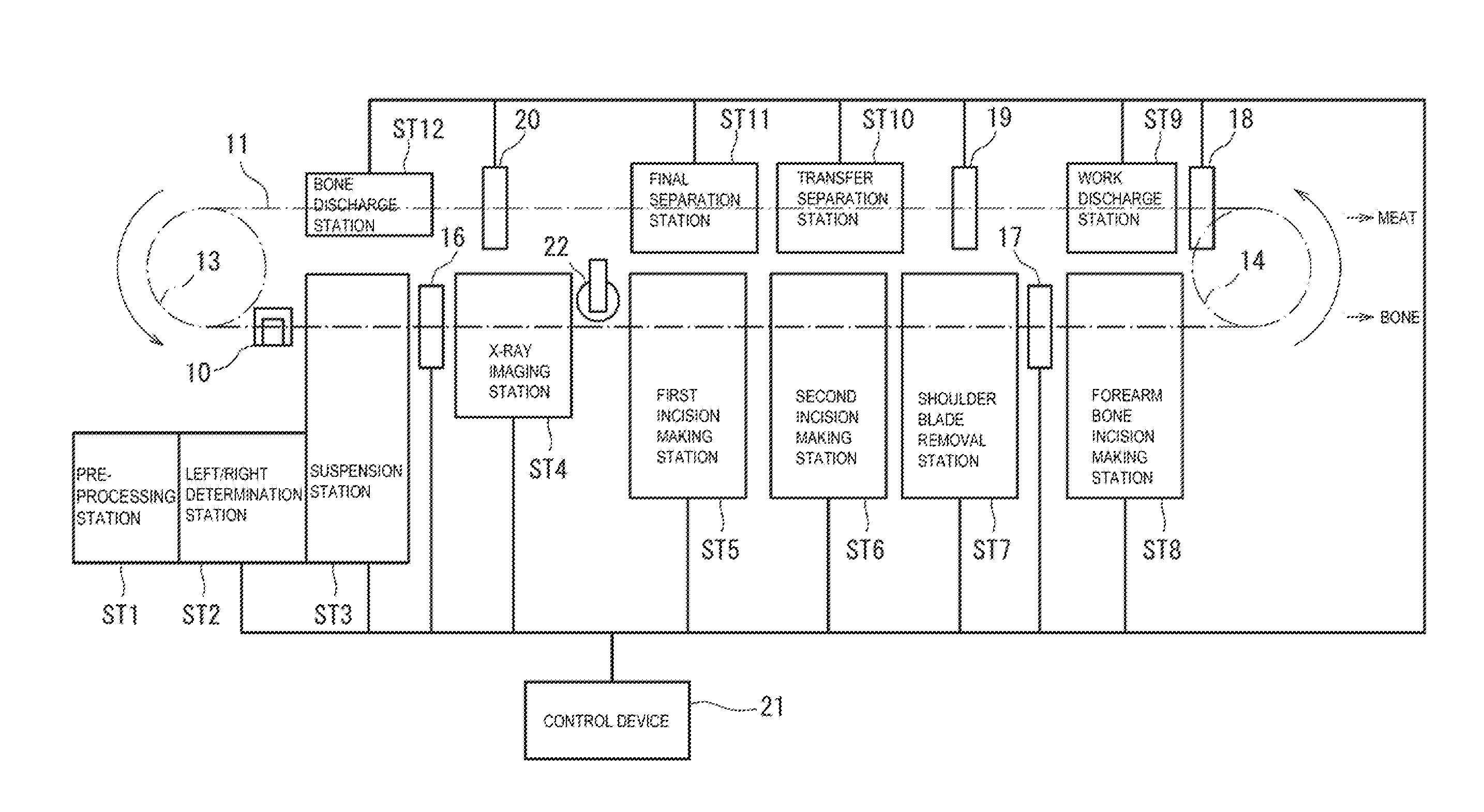

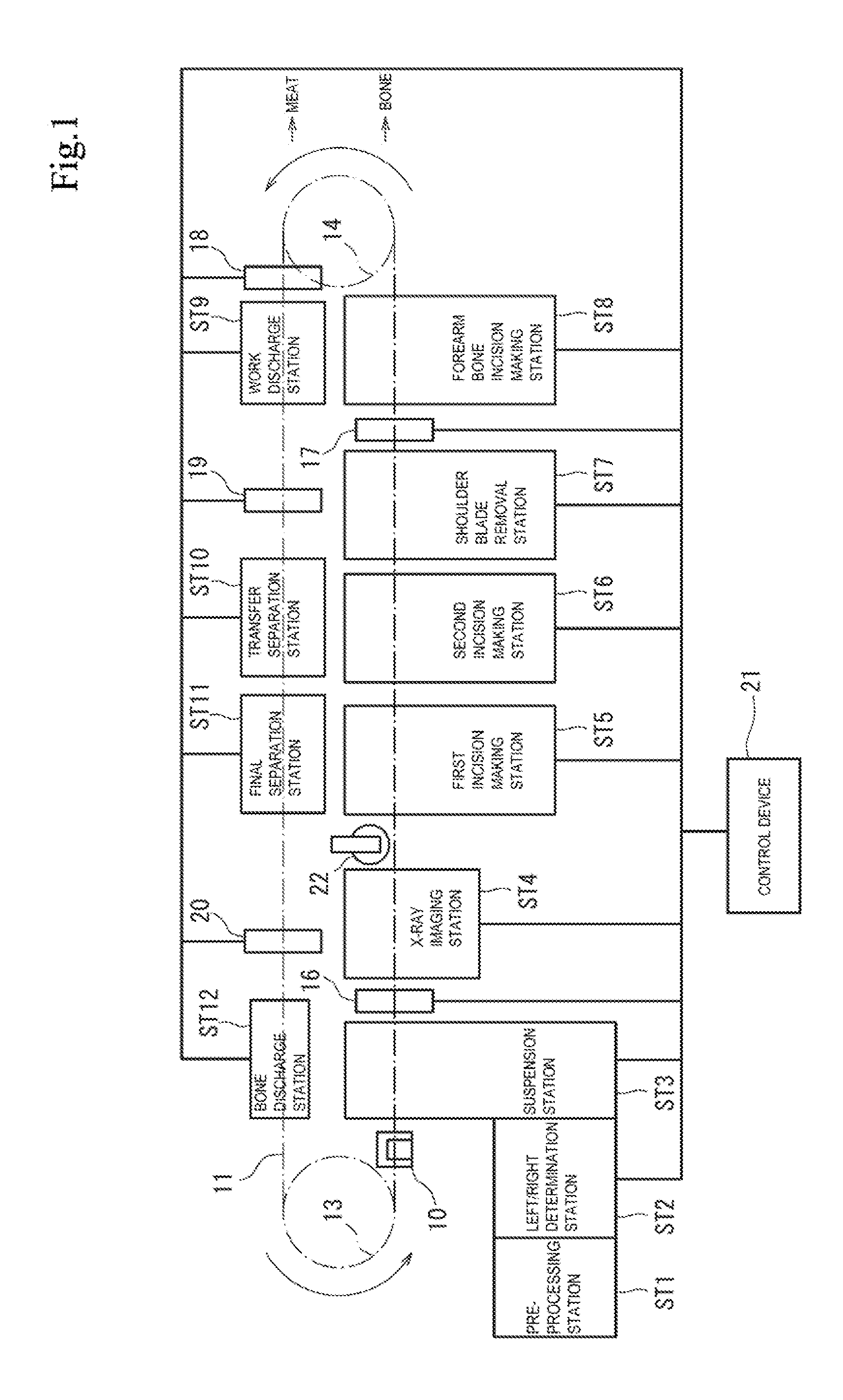

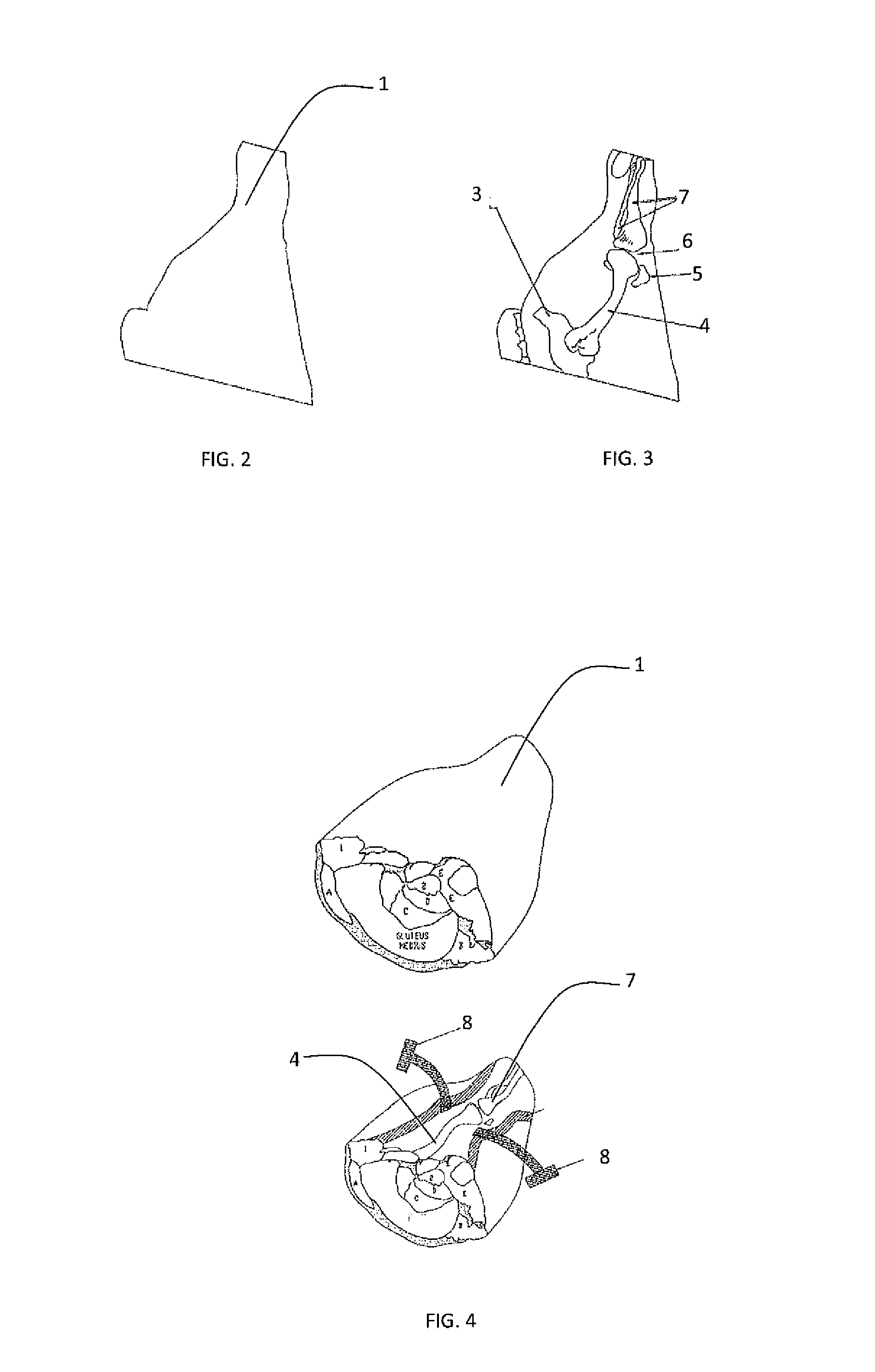

Deboning system of meat

InactiveUS20060030250A1Low costMaximum efficiencyMeat holding apparatusPoultry processingShoulder BladesEngineering

A deboning system of meat for a small or intermediate processing factory in which the space is saved while reduction the cost by limiting the processing range of a work thereby limiting the processing functions to those of high necessity. The deboning system of meat comprises a shoulder blade boning station (11) having a specified interval from a charging station (10) and a humerus deboning station (12) having the same interval disposed sequentially and linearly at a constant interval on the downstream side of the charging station (10). A station (13) for discharging the humerus is disposed on the downstream side of the humerus deboning station (12) and a work is tact-carried while being hanged through fixed and movable carrying passages. The work is deboned during the carrying process, and deboned humerus is discharged from a final station (discharging station) (13).

Owner:MAYEKAWA MFG CO LTD

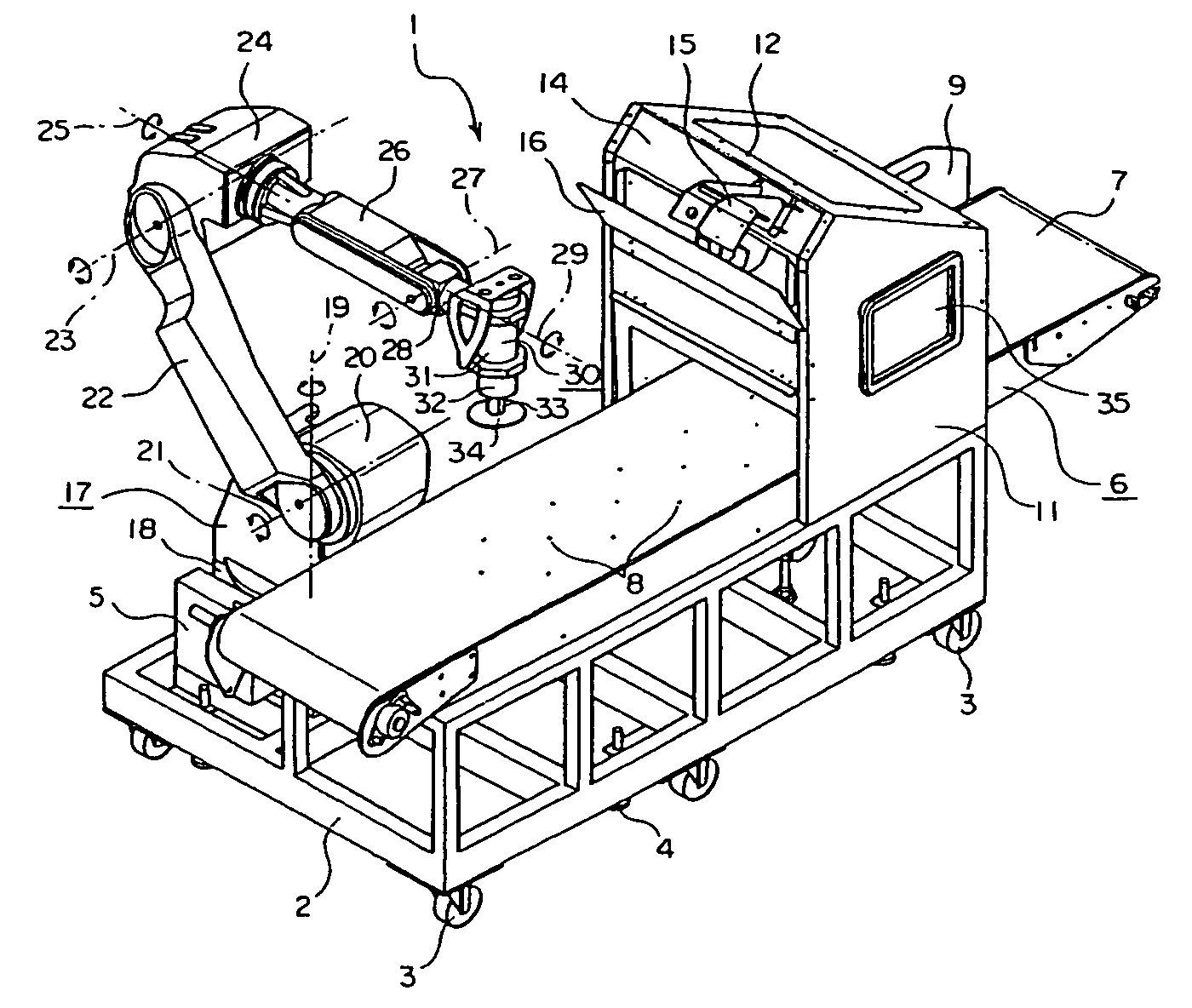

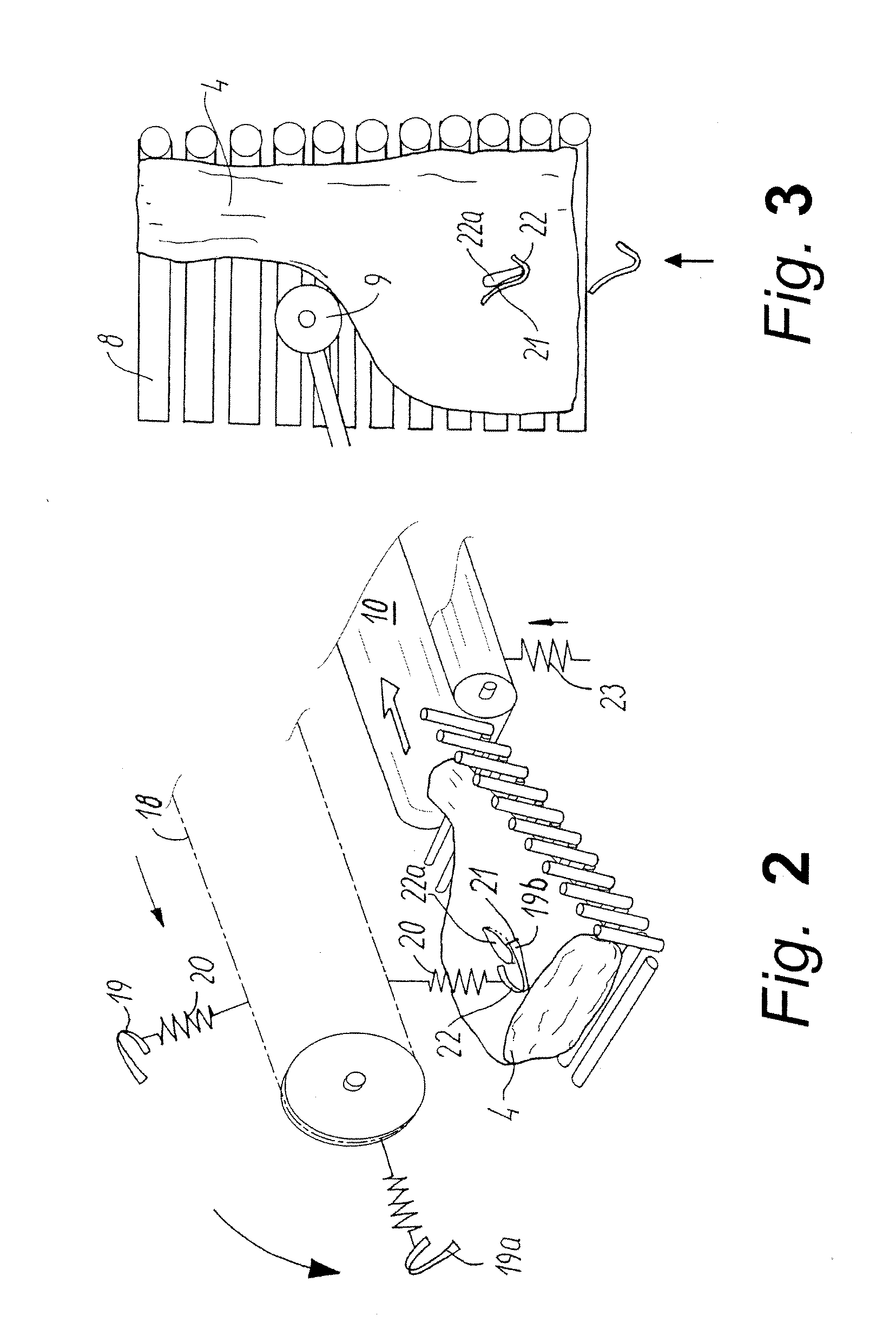

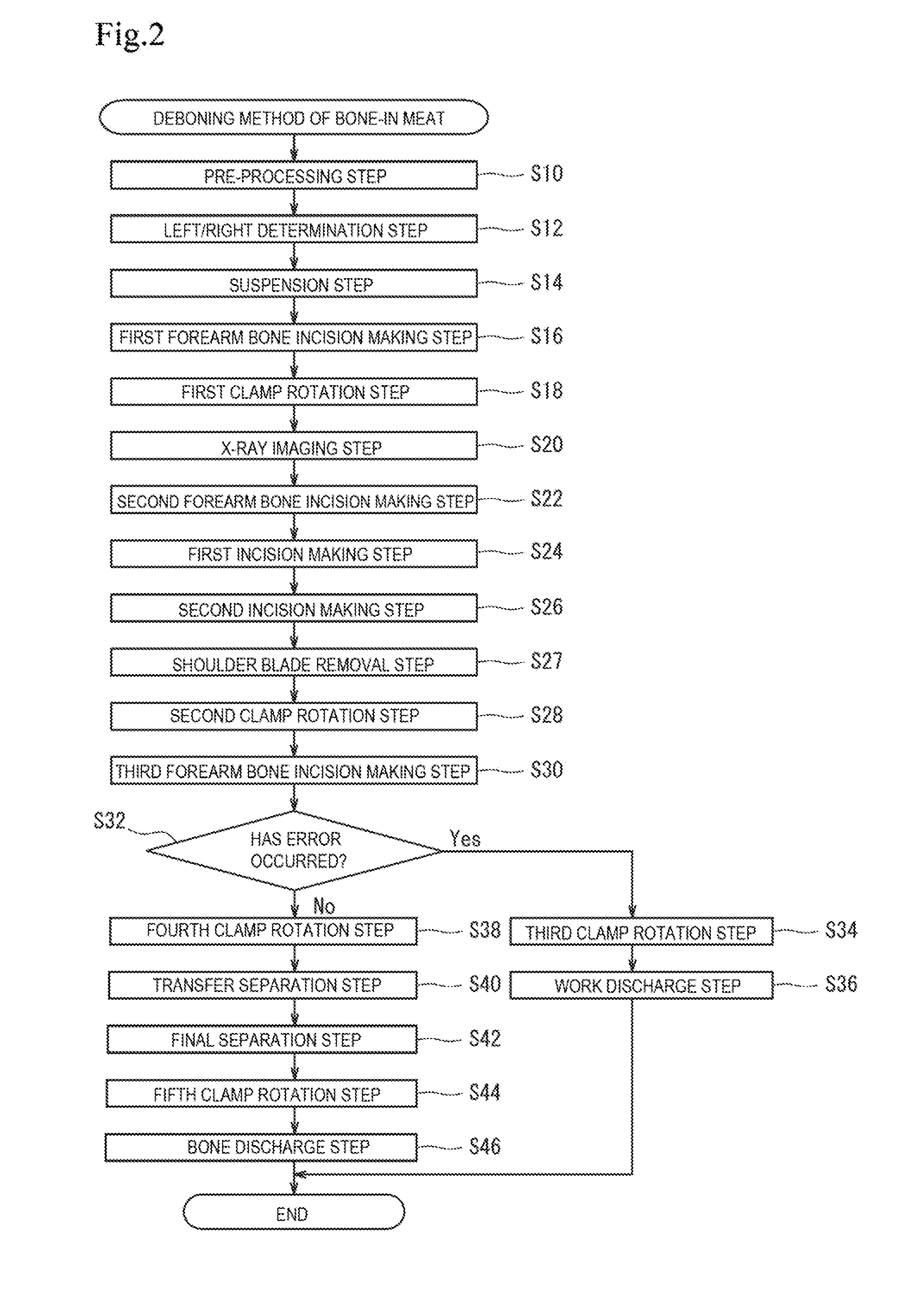

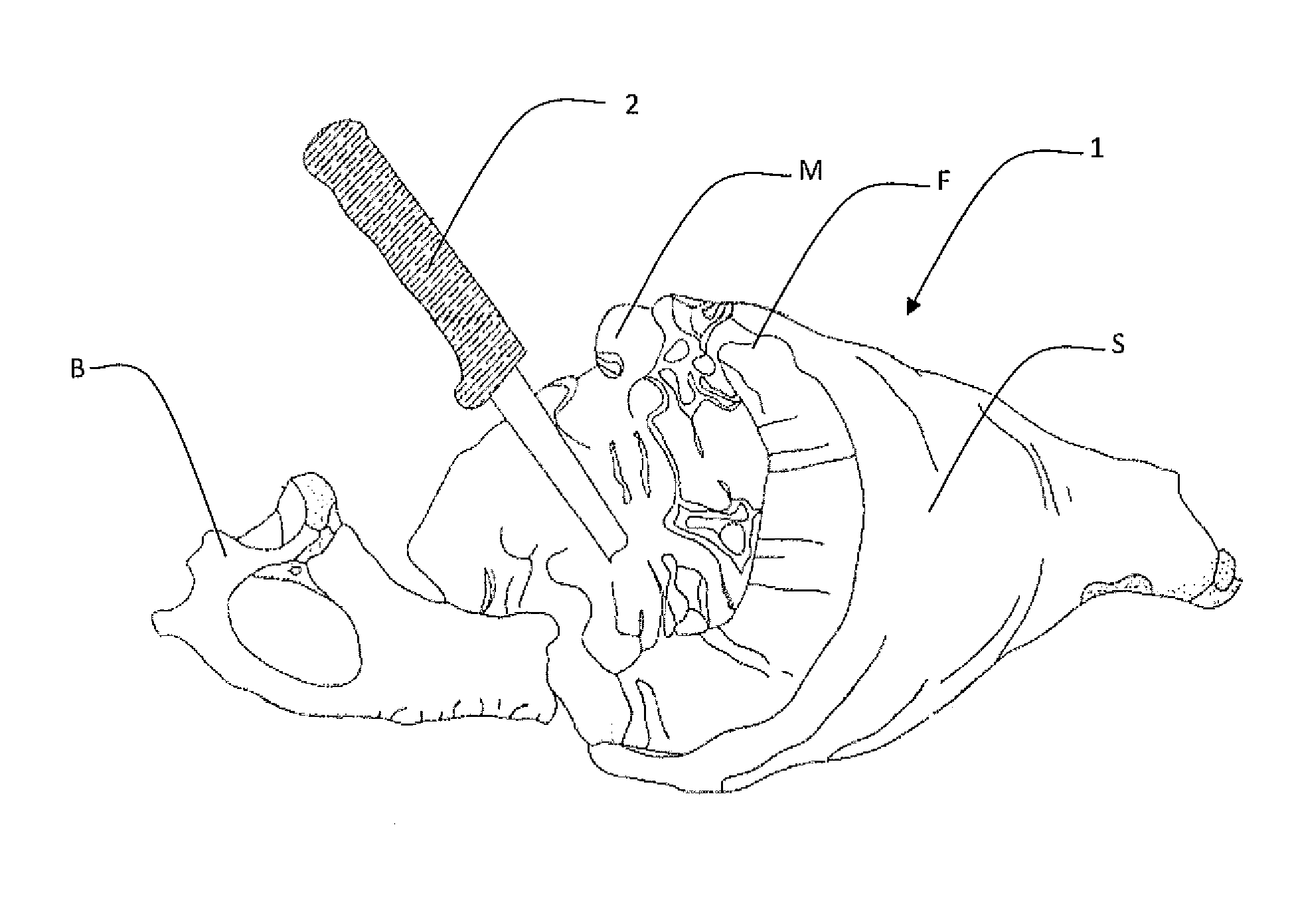

Method of deboning animal meat block and deboning apparatus

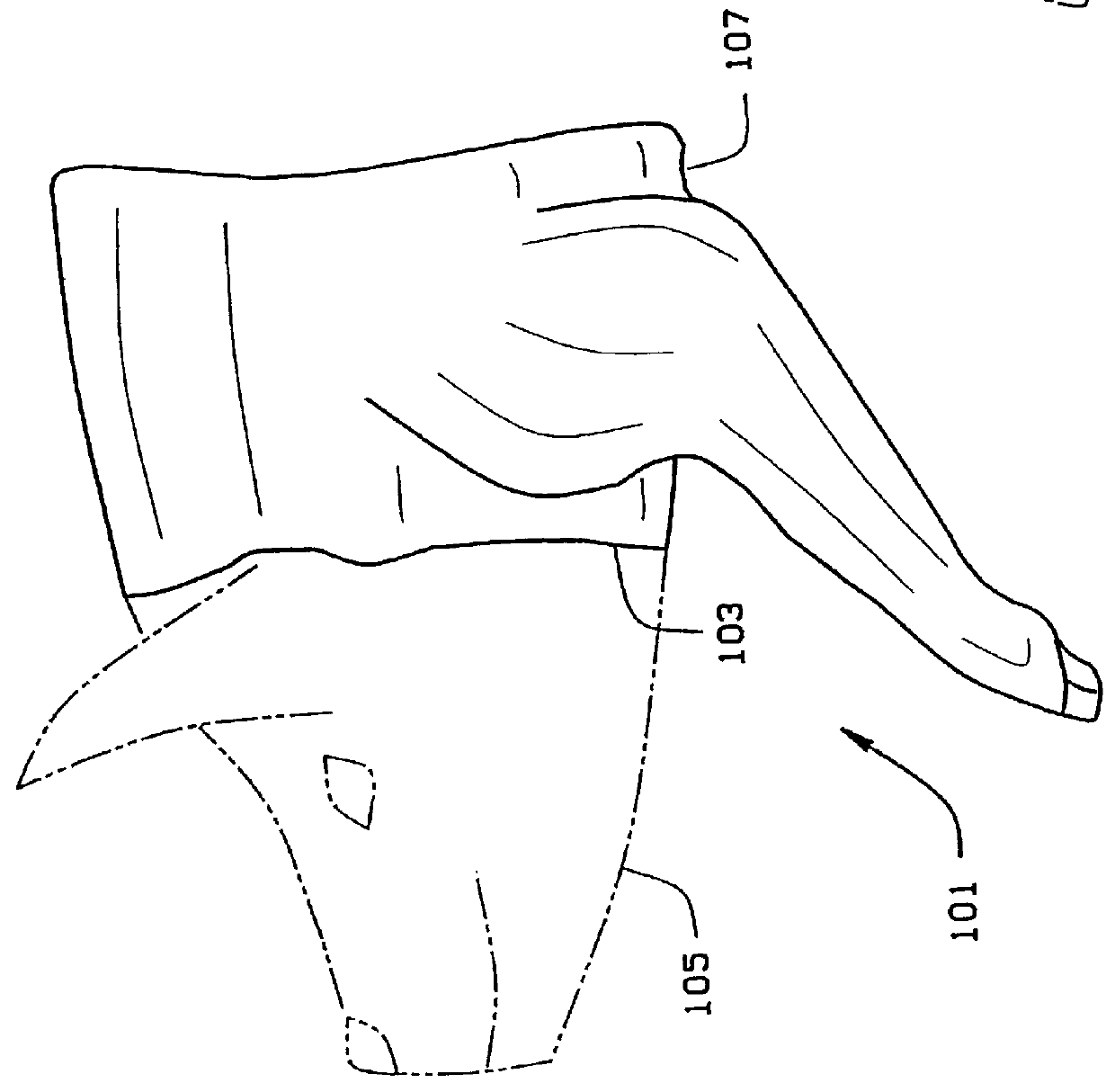

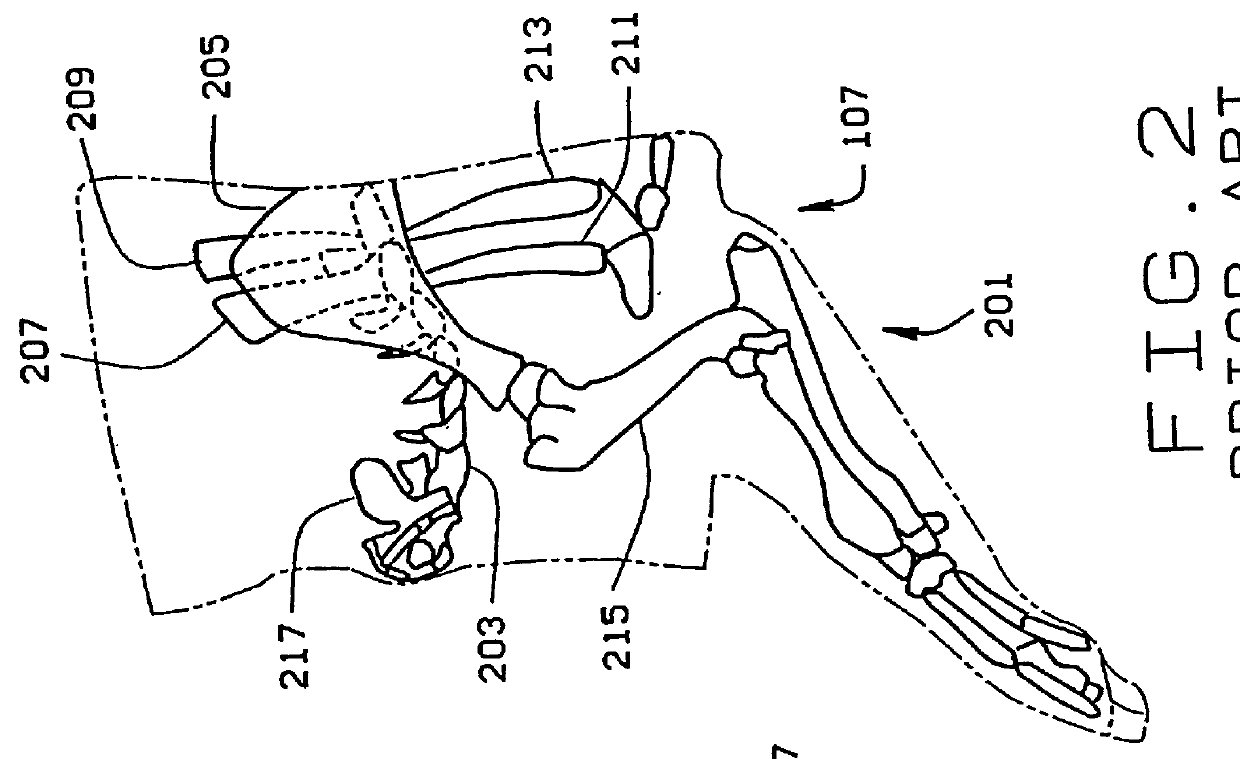

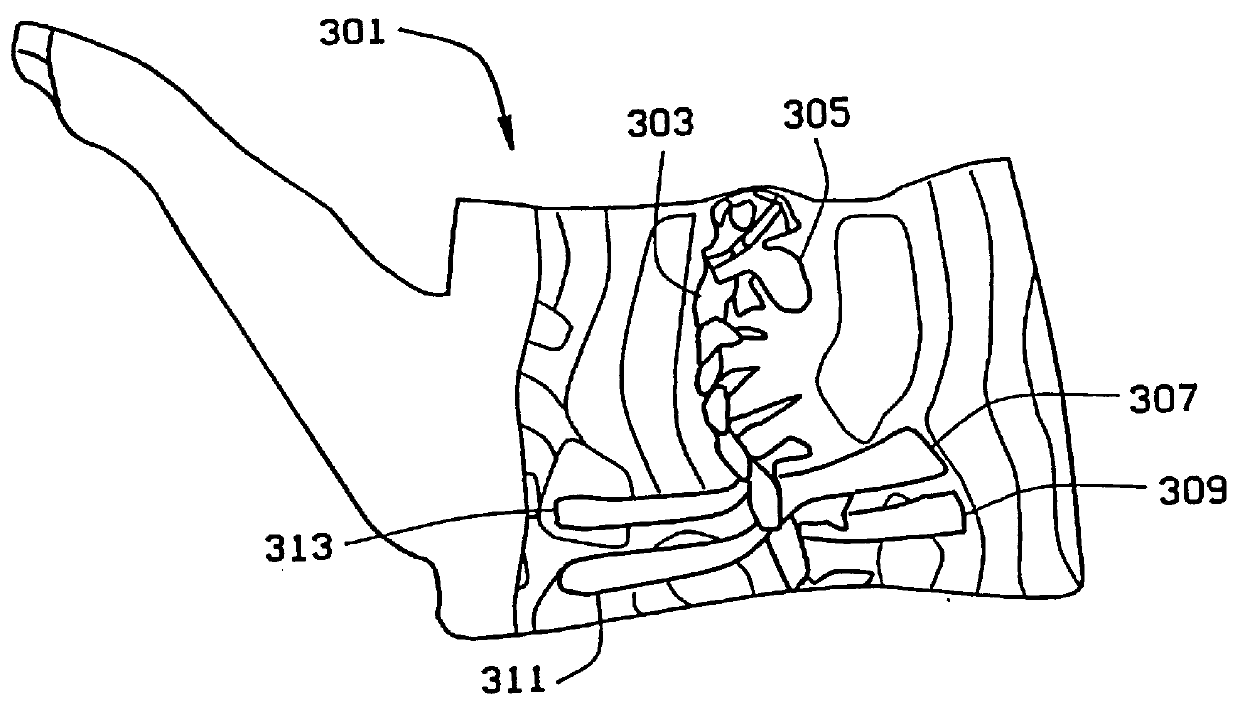

InactiveUS20080020693A1Simple structureSatisfactory separation performanceMeat holding apparatusPoultry deboningEngineeringPre treatment

A deboning method and a deboning apparatus is provided whereby a meat block at the humerus part having a part of the scapula remaining therein, which corresponds to the shoulder part of a back split block of an animal meat (for example, beef, pork, horse meat, goat meat or poultry meat), can be completely automatically deboned after a simple pretreatment by human hand.

Owner:MAYEKAWA MFG CO LTD

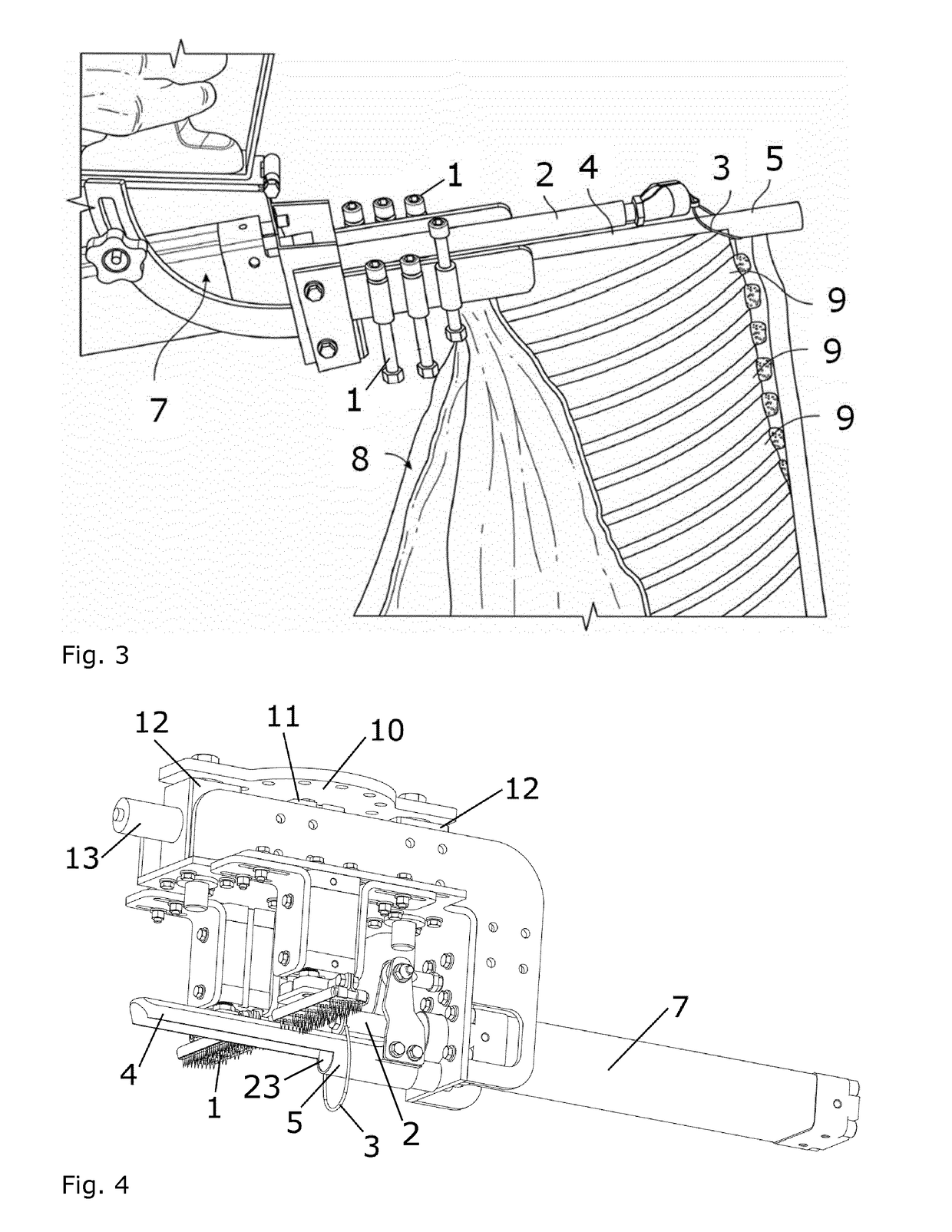

Device for loosening bones from a meat piece such as ribs from a belly piece of slaughtered animal

ActiveUS20190008172A1Programme-controlled manipulatorScattering properties measurementsHand heldEngineering

Disclosed is a device for loosening bones such as ribs from a meat piece from slaughtered animals such as pigs. The bone puller such as rib puller can be hand-held and e.g. pneumatic activated or connected to a robot, and is much easier to use than prior art pneumatic rib pullers and also impose less working stress upon the user. The bone puller may comprise a counter hold for supporting the device towards a belly piece from a slaughtered animal, a string for loosening a bone, a movable pull bar for pulling the string, and a holding-down bar for holding down a bone while loosening this bone. The device may further comprise loading means located at the end of the holding-down bar such that the string can surround the loading means and where this loading means secure feeding of the string around an exposed bone end before loosening this bone.

Owner:TEKNOLOGISK INST

Method for automatic cutting of hams, and an apparatus for automatic cutting of hams

InactiveUS20100009614A1Convenience to workPrecise positioningMeat processing plantsPoultry processingSpring forceSide lying

A method and an apparatus for automatic cutting of hams, with the hams conveyed on a first conveyor inwards below and to engagement with a carrier for the pubic bone of the ham, which is held by the carrier. The ham is conveyed further on by a second conveyor and an overhead conveyor for the carrier with the rind side lying on the second conveyor, where the pubic bone is pressed by a spring force against and is held by the carrier in a predetermined, vertical position. Cutting devices for the cutting of the hams are arranged at these conveyors. This apparatus and method makes it possible to position the hams precisely relative to the cutting tools which are to process tailbone, groin meat, groin fat and fat edge, irrespective of the sizes of the hams, owing to the engagement of the pubic bone with the carrier.

Owner:SLAGTERIERNES FORSKNINGSINSTITUT

Meat fabrication system and method

The present invention includes meat fabrication systems and methods. The system according to one embodiment includes a conveyor (104) for advancing meat cuts, a cutting assembly (106) defining a cutting path (136) that intersects the conveyor (104), and at least one guide (160, 162, 163) that orientates the meat cuts on the conveyor relative to the cutting path such that the chine bones of the meat cut are separated from the remaining portions of the meat cuts as the meat cuts are advanced through the cutting path (136) by the conveyor (104).

Owner:CARGILL INC

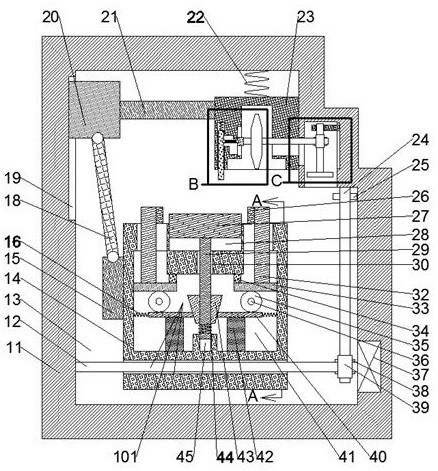

Processing machine body capable of cutting and boning meat

The invention discloses a processing machine body capable of cutting and boning meat. The processing machine body capable of cutting and boning meat comprises a processing machine body, wherein a processing cavity with a forward opening is formed in the processing machine body. The processing machine body is mainly applied to the daily boning processing of meat, in the processing process, a clamping mechanism is triggered through the movement of a pressed block, then the clamping fit of a part to be processed is achieved, in the moving process of a movable base, through the cooperation of a lifting sliding block and a cutting base, a cutting tool is driven to move downwards to cut the part to be processed, the cutting tool can be rotated through meshing of a driven gear and a driving gearin the cutting process by means of a rotating mechanism, and meanwhile, the final boning treatment can be performed on the part to be processed after cutting through a boning base and a through cavityto obtain complete boneless meat.

Owner:宁波奉化困光啤酒酿造技术有限公司

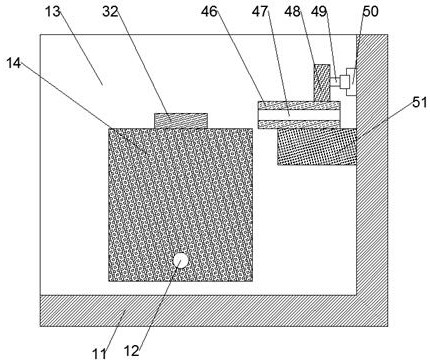

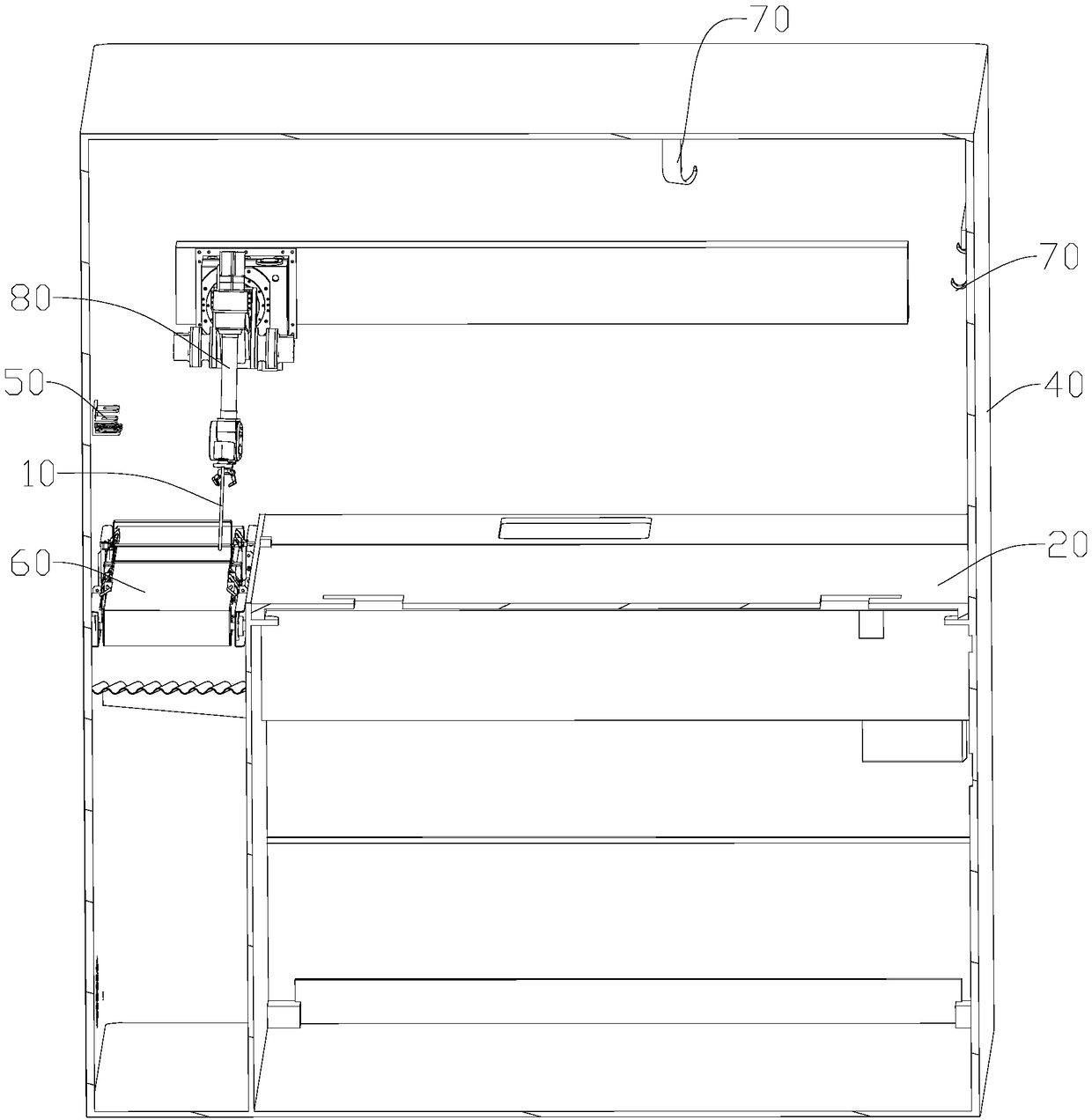

Livestock processing device

PendingCN108142533ARealize cutting and separating operationReduce operating proceduresSlaughtering accessoriesMeat deboningLean meatEngineering

The invention discloses a livestock processing device. The livestock processing device comprises a working table, a manipulator, a cutting and layering device and a machine frame with hooks, wherein the working table is mounted on the machine frame, and is used for supporting livestock; a cutter is mounted on the manipulator; the manipulator is used for driving the cutter to cut the livestock on the working table into a plurality of parts, and is also used for hanging parts with bones and meat of the livestock to the hooks, and driving the cutter to reject the meat of the parts; and the cutting and layering device is used for separating the fat meat from lean meat of the livestock. According to the livestock processing device disclosed by the invention, through the cooperation of the manipulator, the hooks, the cutter and the cutting and layering device, various processing operations on the livestock are realized, and the operation procedures of sellers are greatly reduced, so that thelabor intensity is reduced.

Owner:傅峰峰

Device and method for conveying bone-in meat and deboning system of bone-in meat including the device

ActiveUS9033774B2Increase automation rateMeat/sausage hanging-upMeat packaging/handling/transportingBand shapeActuator

Two hooking members of a hooking unit used in a device for conveying bone-in meat respectively have belt-like main body parts, blade-like pointed ends provided at ends on one side of the main body parts, and barbs provided on first sides of the main body parts to be continuous with the points. The hooking members are supported so as to be in parallel with each other with an elastically changeable interval therebetween and to be rotatable about rotation axes along longitudinal axes of the main body parts. Further, the hooking unit has an actuator which rotates the hooking members about the rotation axes.

Owner:MAYEKAWA MFG CO LTD

Method and apparatus for separating meat from bone

A separator apparatus that separates meat from bone in two distinct separation stages includes a rotary cam pump in series with a deboning screw assembly. In the first separation stage, substantially bone-free meat is separated from bone as the meat-bone mixture passes through the rotary cam pump, and expelled from the separator apparatus. The rotary cam pump then drives the remaining meat bone mixture into the deboning screw assembly, where a second separation stage occurs in which additional substantially bone-free meat is separated from bone as the meat-bone mixture passes through the deboning screw assembly, and is also expelled from the separator apparatus. The remaining bone residue is expelled from a bone residue outlet on the separator apparatus. The meat separated during the first stage can have a different coarseness than that separated during the second stage, and each can be expelled and collected at a different location.

Owner:POSS DESIGN LIMITED

Cutting device; separator; method for separating food components by means of a separator

ActiveUS20200298245A1Vary width of gapLow costGrain treatmentsMeat deboningProcess engineeringIngested food

A cutting device, a separator and a method for separating food components using a separator compensates the effects which an increasing wear on a cutting tool arranged on a rotating body have on comminuting a foodstuff by movably arranging the cutting tool on the rotating body.

Owner:MASCHFAB SEYDELMANN

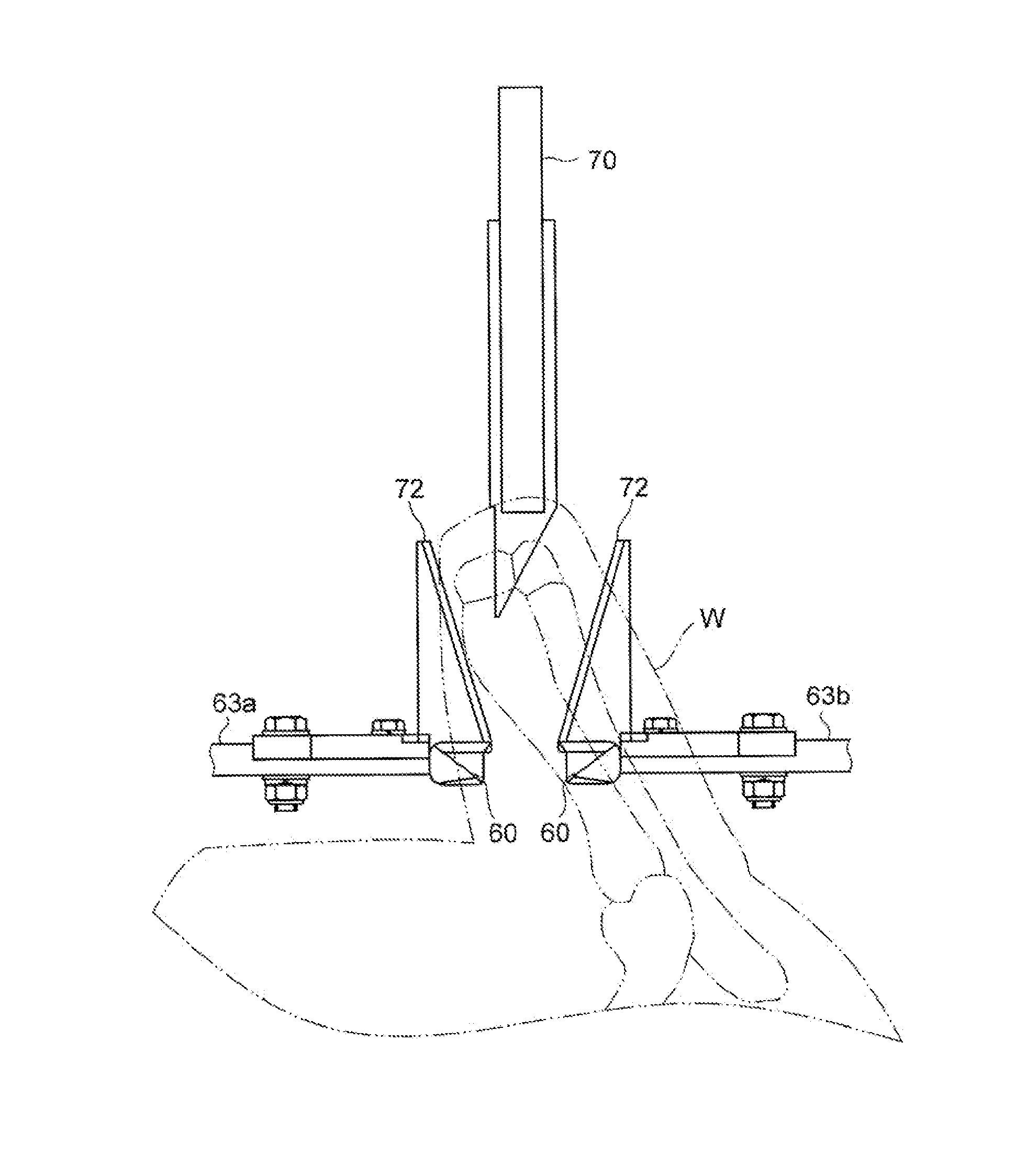

Device and method for capturing X-ray image of bone-in meat and deboning system of bone-in meat including the device

ActiveUS9513234B2Decrease of loadDecrease of yieldRadiation/particle handlingMeat packaging/handling/transportingSoft x rayX-ray

An X-ray image capturing device of bone-in meat for capturing an X-ray image of the bone-in meat that is from an arm part or a thigh part of a livestock carcass in a state where the bone-in meat is suspended, comprises: an X-ray source for irradiating the bone-in meat with an X-ray; a shielding box for covering the bone-in meat while the X-ray image is captured; a sensor which is disposed in the shielding box and which detects the X-ray which passes through the bone-in meat; and a filter which is disposed between the bone-in meat and the X-ray source and which adjusts an intensity distribution of the X-ray with which the bone-in meat is irradiated.

Owner:MAYEKAWA MFG CO LTD

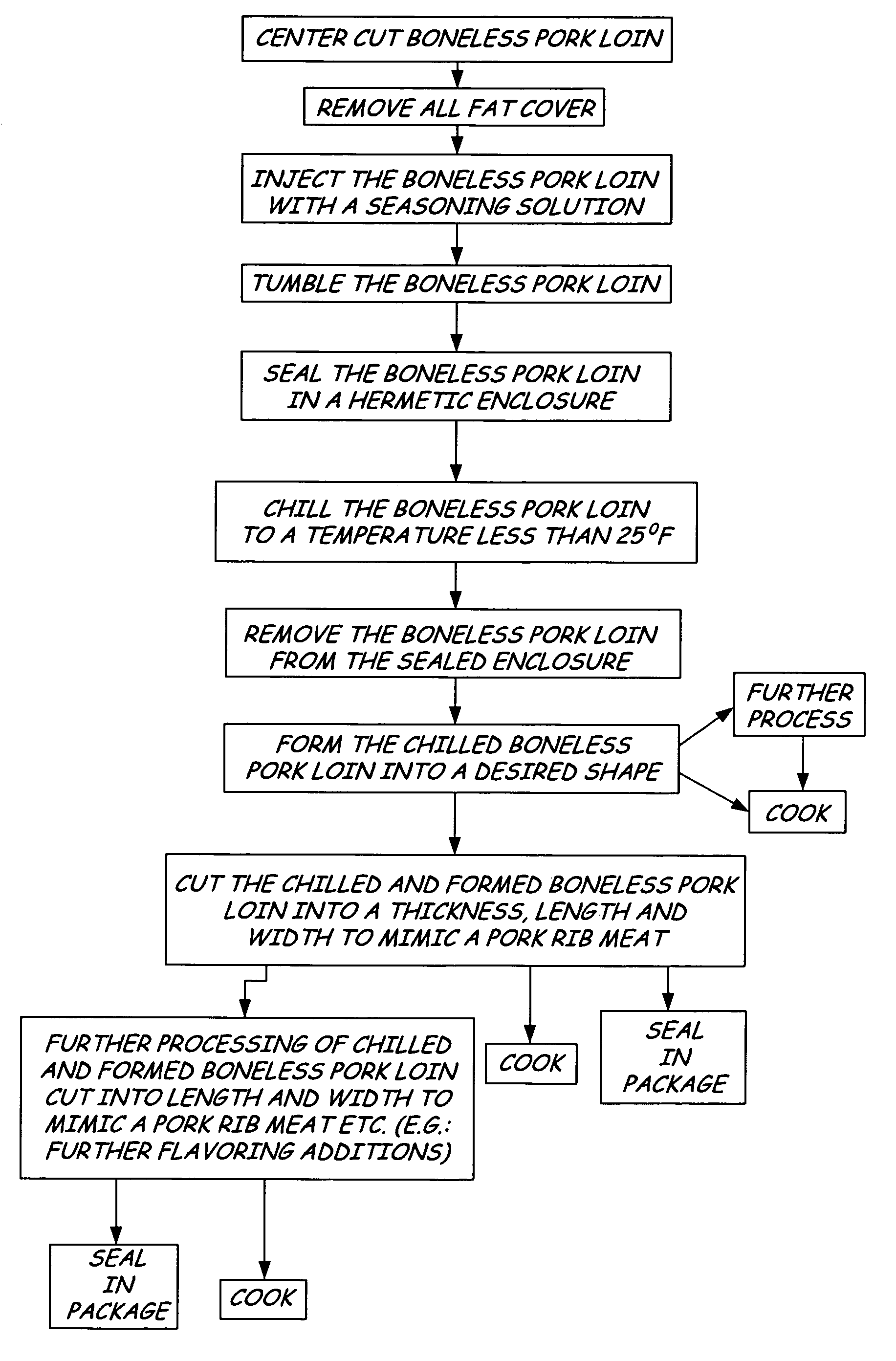

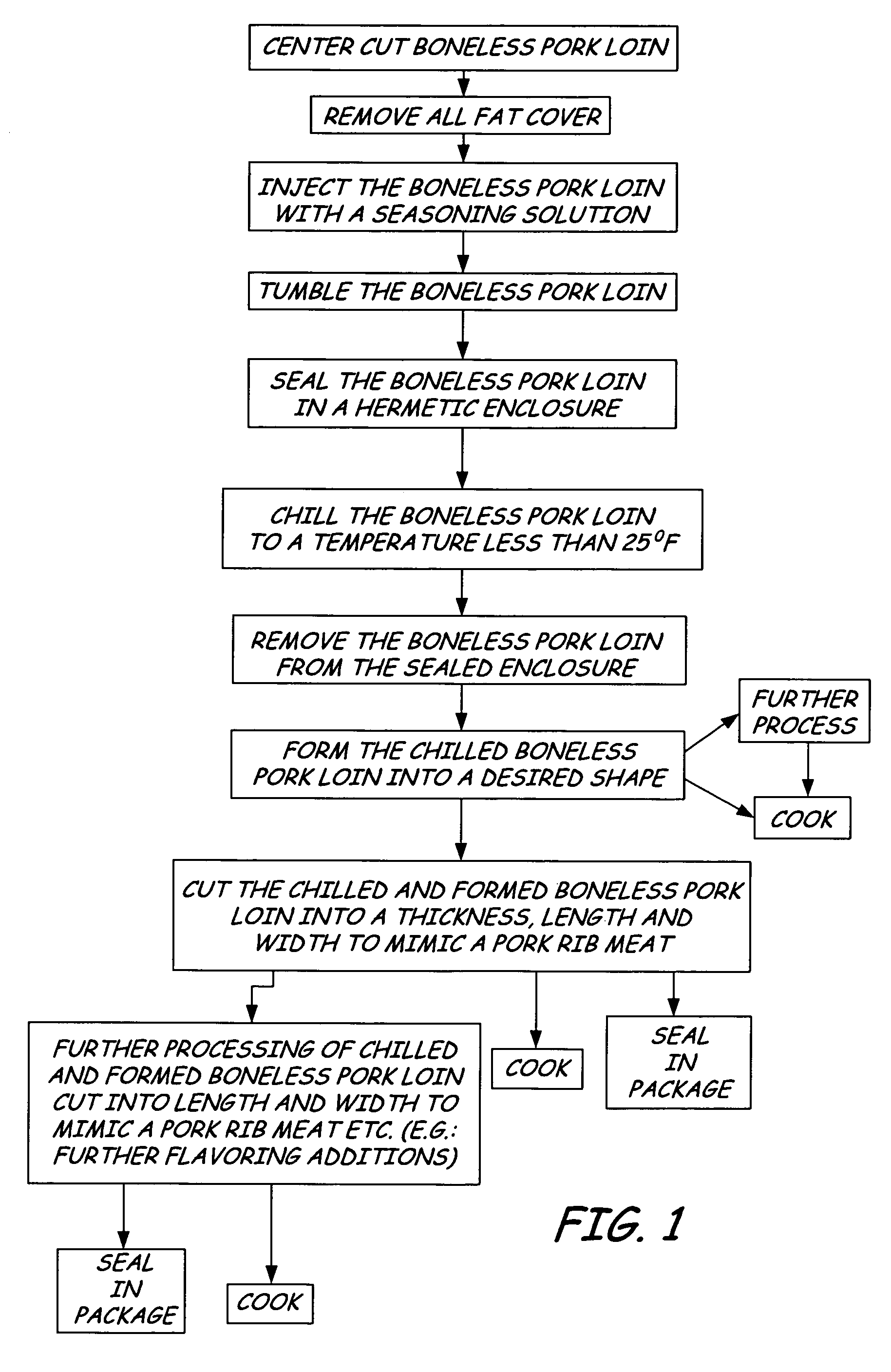

Process for making pork chops

The present invention is a method for cutting pork to create a meat cut that mimics a pork chop meat. The method involves removing the bone and meat from the pork leg. The method then includes sealing the pork chop within a hermetic enclosure and chilling the enclosed pork chop to a temperature in the range of 35 to 38 degrees Fahrenheit. The resulting meat cut includes, bones or no bones pork chops.

Owner:TORRENS FIGUEROA EDGARDO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com