Clutch body of a synchronisation device of a variable speed transmission of a motor vehicle and method for the production thereof

A technology of gear transmission and synchronous device, which is applied in the direction of mechanically driven clutches, clutches, mechanical equipment, etc., and can solve problems such as the realization of a stable process and the technical limit of the modification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

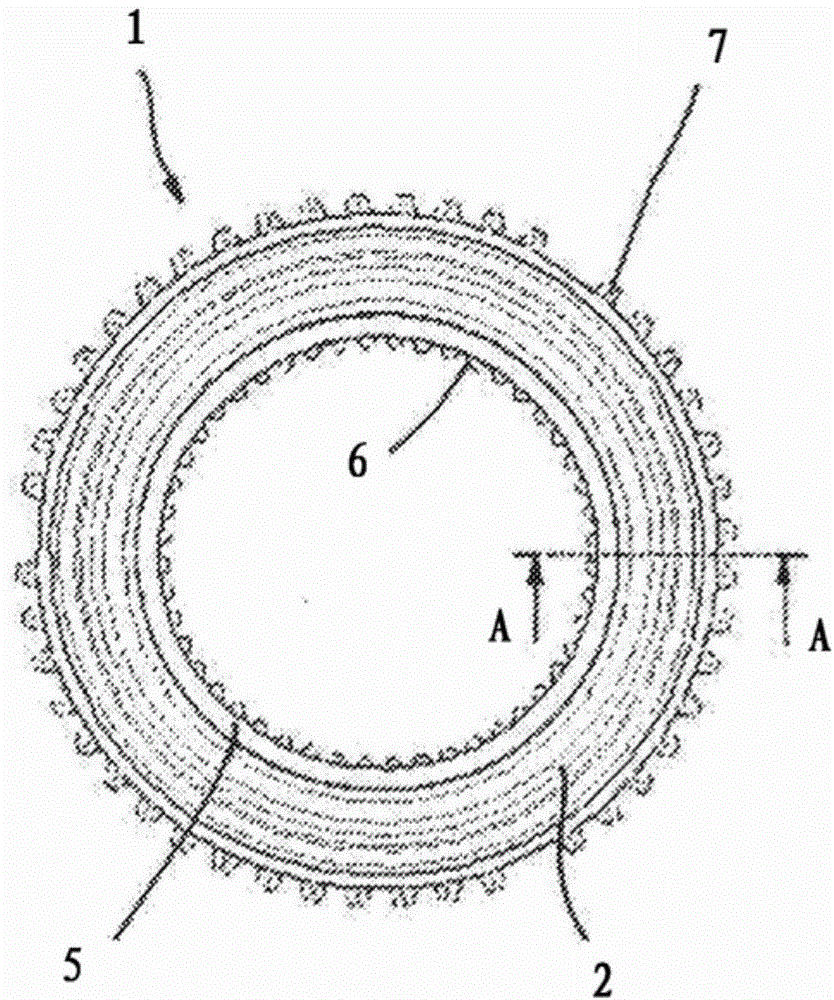

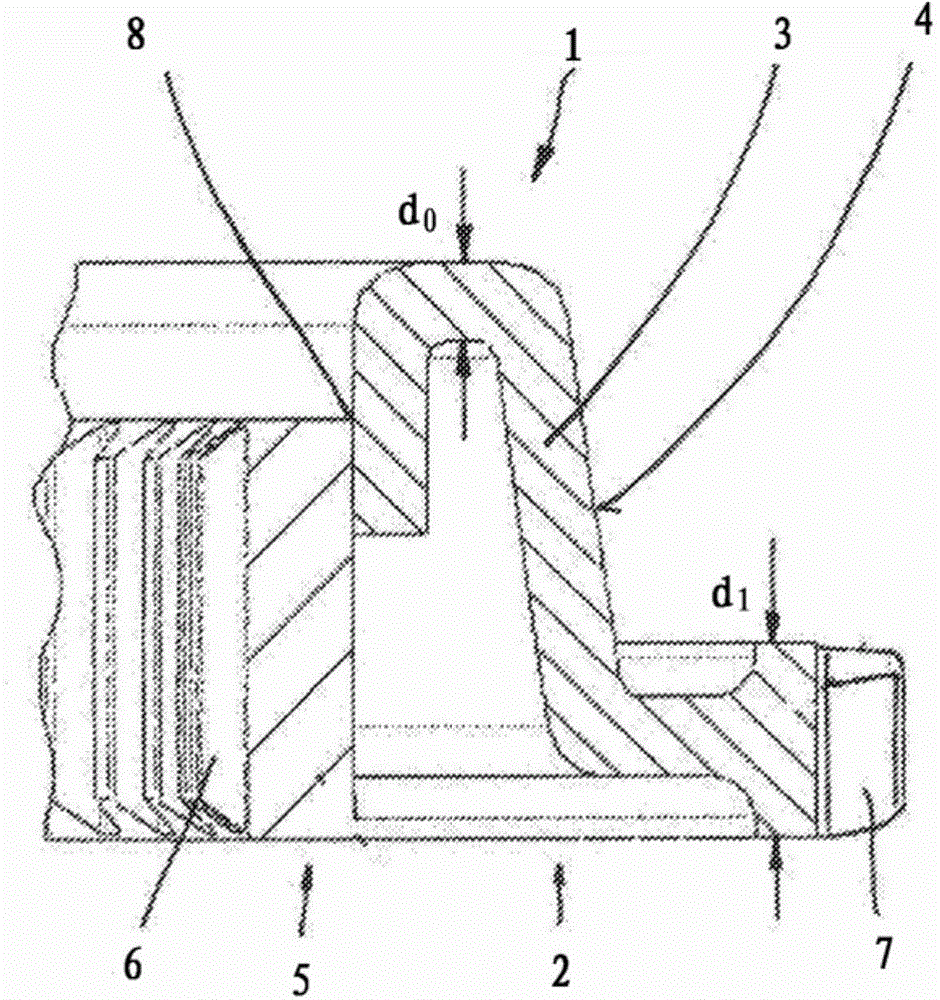

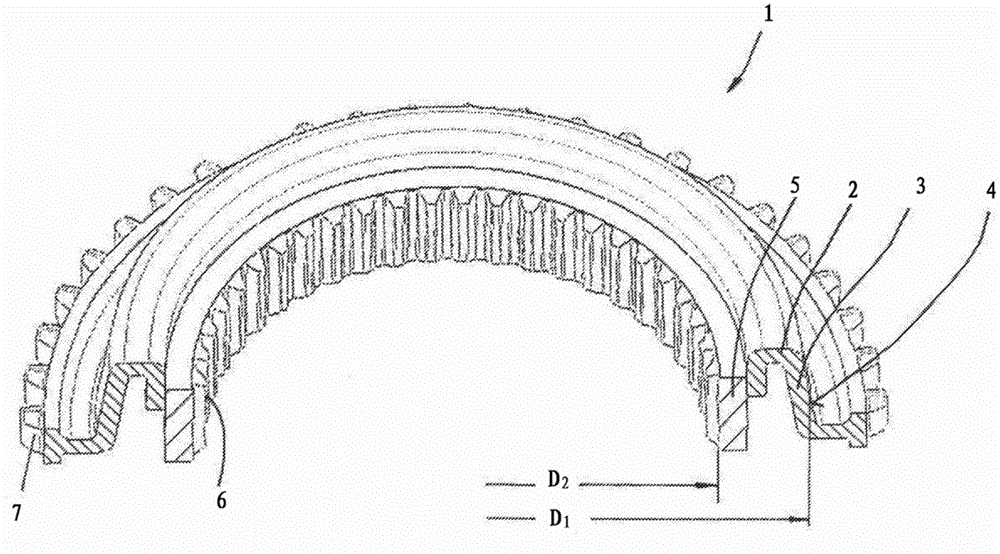

[0027] The figures show different views of a coupling body 1 which belongs to a synchronizing device of a motor vehicle gear transmission. The coupling body 1 is designed in two parts. It has a radially outer coupling disk section 2 and a radially inner carrier section (ie hub) 5 .

[0028] The coupling disc segment 2 is manufactured from a steel disc having an original thickness d 0 . Formed by stamping and bending or deep drawing as especially from figure 2 The shape obtained from . The coupling disk section 2 therefore has a friction cone 3 with a wedge-shaped friction cone surface 4 .

[0029] In the radially outer region, the plate material of the coupling disk section 2 is thickened by a rolling process, ie it is realized by extrusion of the material to have a thickness corresponding to the initial thickness d 0 Compared to greater thickness d 1 section. The toothing 7 is then inserted in the radially outer section, for which the rolling process is again applied....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com