Method for starting an electric motor in a hydraulically operated working machine

A technology for hydraulic excavators and hydraulic pumps, which is applied in the field of asynchronous motors and can solve problems such as voltage interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

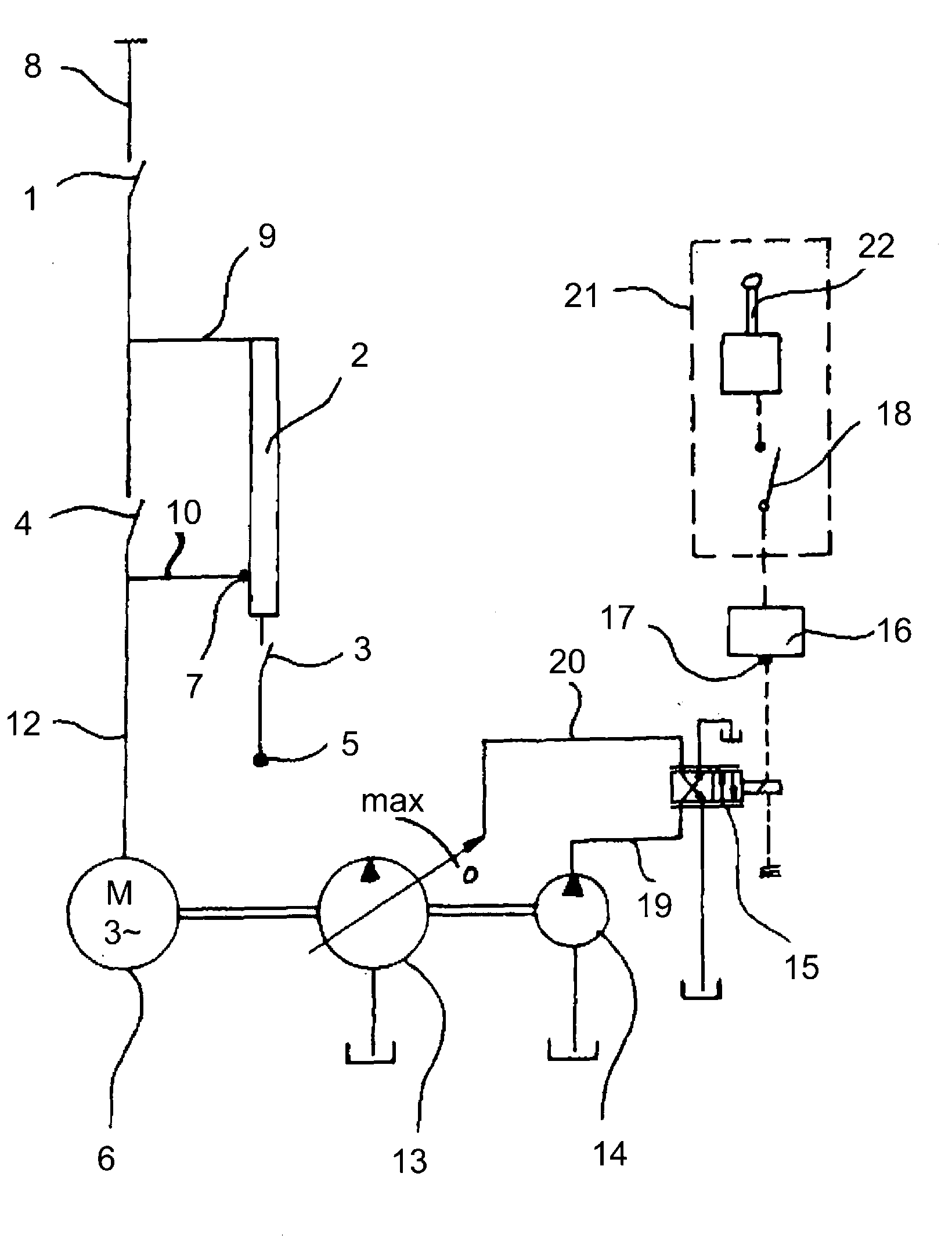

[0018] figure 1 The base state (non-operating state) is shown in which a voltage is applied to the open switch 1 via the line 8 . The delivery volume V of the hydraulic pump 13 has the value zero.

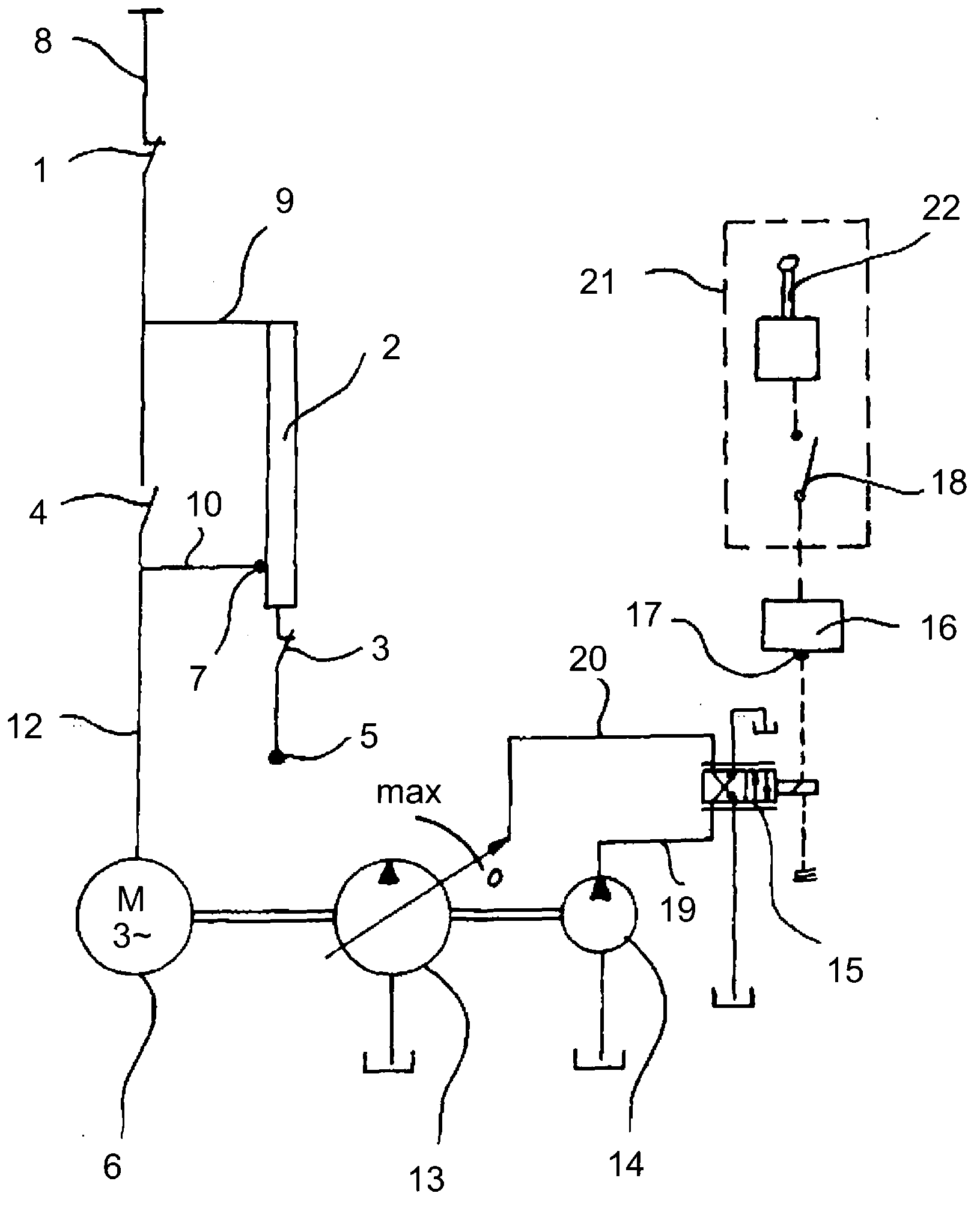

[0019] figure 2 The first control stage of the start-up process of the electric motor 6 of a hydraulic excavator (not shown in detail) with a service weight (gross weight) > 100 t is shown. Switching elements 1 and 3 are closed. The current flows through the closed switching element 1 and via the electrical lines 8 and 9 to the transformer 2 . Switching element 3 to star point 5 of transformer 2 is closed. As a result, at the branching point 7 of the transformer 2 a part of the current / electrical shunt is output via the electrical lines 10 and 12 to the electric machine 6 . In this example, the delivery volume V of the hydraulic pump 13 designed as an axial piston pump is again at the value zero.

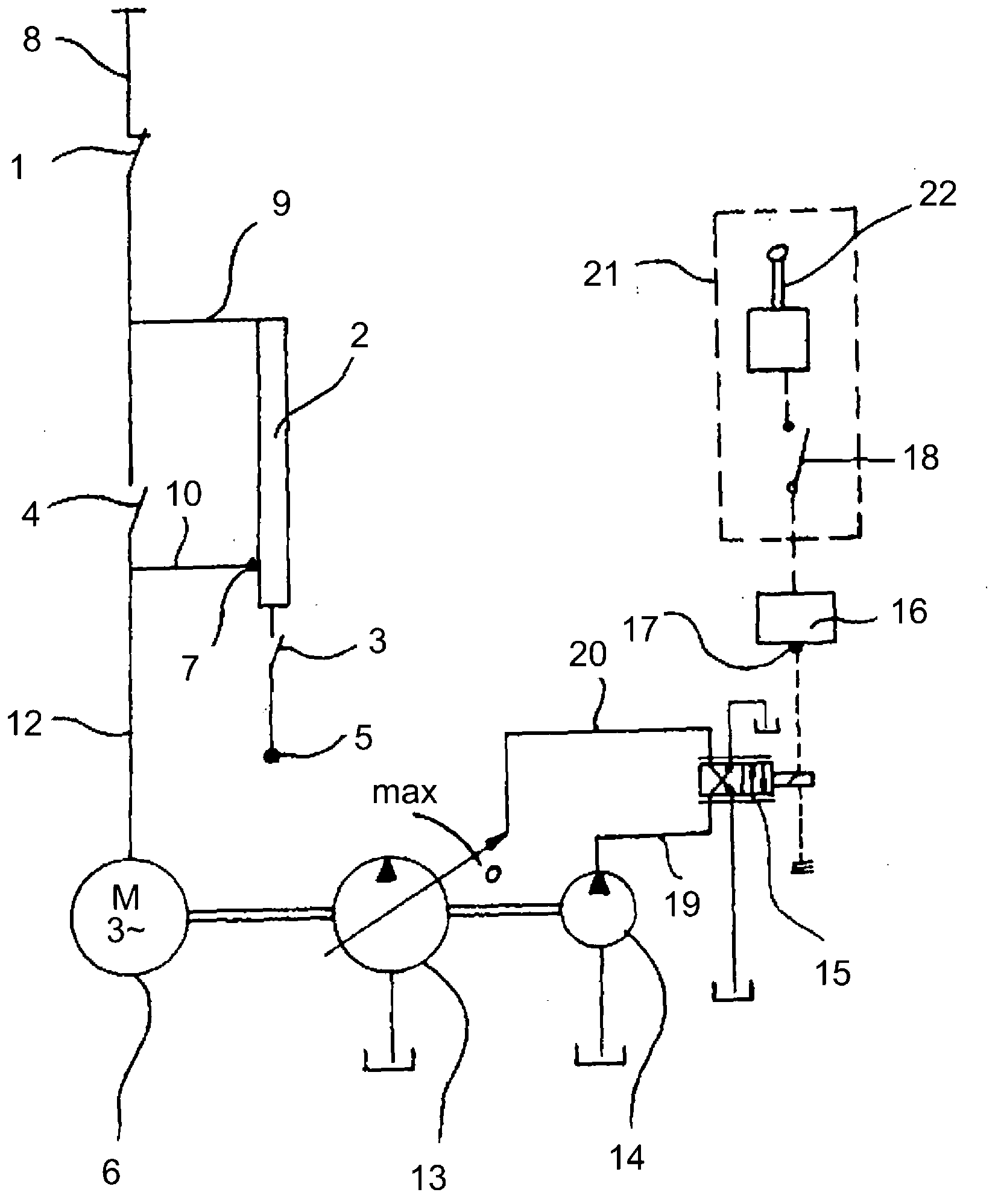

[0020] image 3 The second control level of the start-up process is shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com