Layered product

A technology for laminates and heating elements, applied in the direction of layered products, synthetic resin layered products, flexible coverings, etc., which can solve problems such as discomfort, broken bags, damage to the softness and texture of laminates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

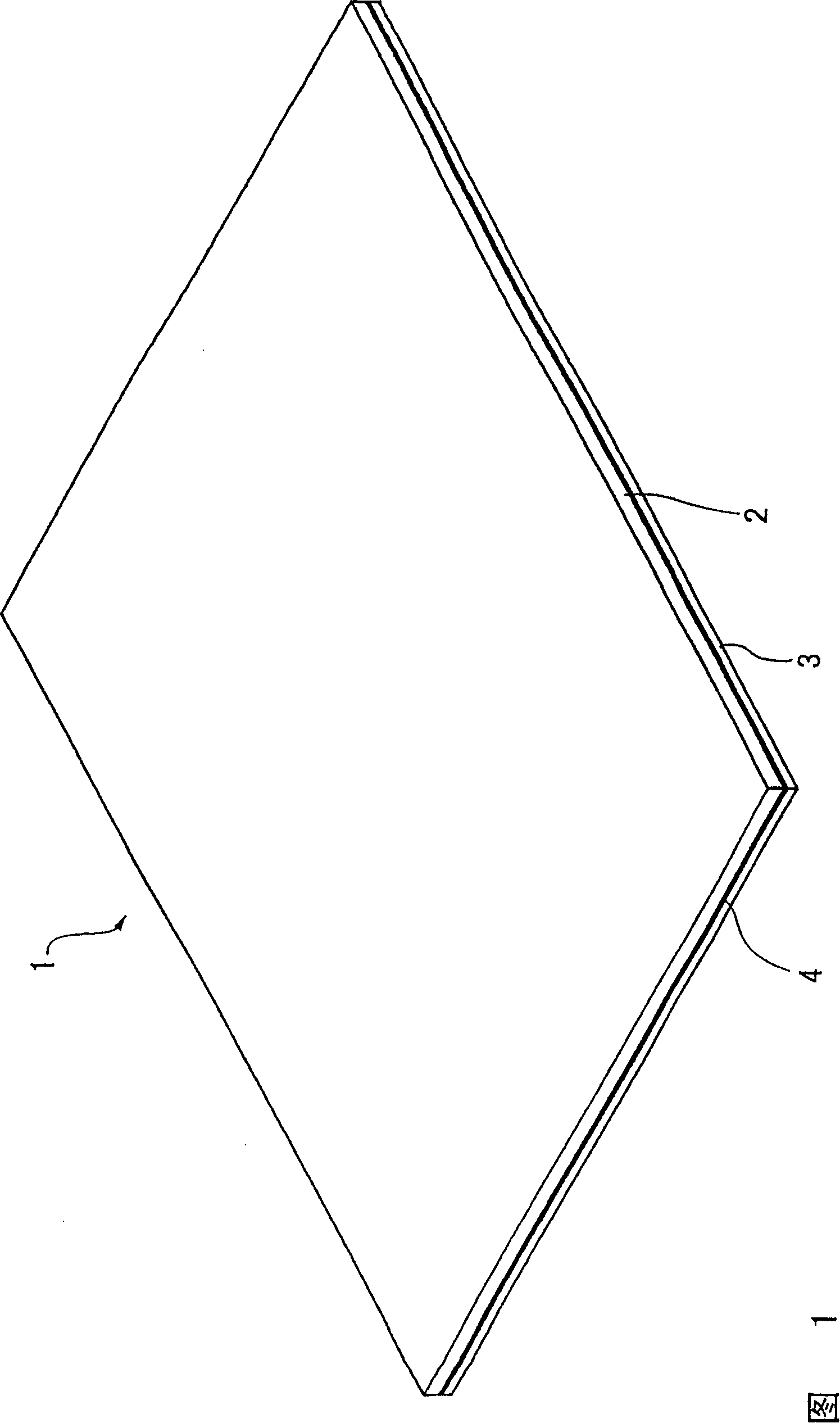

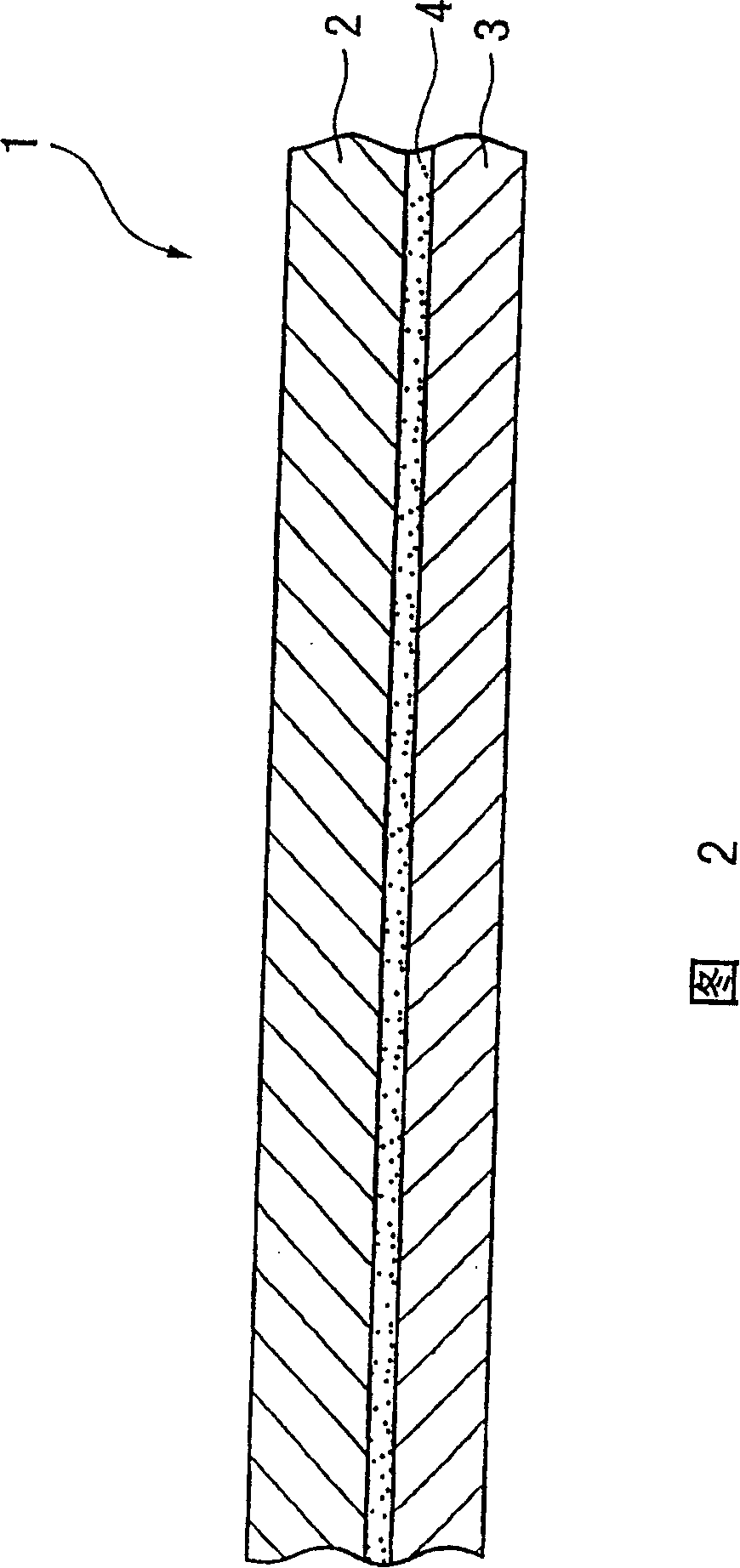

[0061] As shown in FIGS. 1 and 2 , the laminated body 1 of this embodiment adopts a structure in which a polypropylene nonwoven fabric 2 and a thermoplastic resin layer 3 are laminated, and the polypropylene nonwoven fabric 2 and the thermoplastic resin layer 3 are laminated. Interlayer resin 4 is provided therebetween.

[0062] As the polypropylene-based nonwoven fabric 2 constituting the laminate 1 of the present embodiment, a 10% modulus in the MD direction at an ambient temperature of 100° C. measured by a method based on JIS L1096 is 15 N / 50 mm or more.

[0063] Furthermore, as the polypropylene-based resin constituting the polypropylene-based nonwoven fabric 2 in the present embodiment, a polypropylene-based resin having a stereoregular NMR value (mmmm ratio) of 95% or more and an isotactic pentad ratio of 98% or more is used. Homopolypropylene with high stereoregularity, the material has a melting point of about 164°C. Furthermore, as the type of nonwoven fabric, a spu...

no. 2 Embodiment approach

[0092] This embodiment is basically the same as the above-mentioned first embodiment, and redundant description of the same configuration will be omitted. Next, differences from the aforementioned first embodiment will be described.

[0093] In the aforementioned first embodiment, the 10% modulus in the MD direction at 100° C. of the polypropylene-based nonwoven fabric 2 is 15 N / 50 mm or more. On the other hand, in the present embodiment, the 10% modulus in the MD direction as the entire nonwoven fabric laminate 1 is 65 N / 50 mm or more at normal room temperature.

[0094] In the aforementioned first embodiment, the thermoplastic resin layer 3 has a single-layer structure composed of a polypropylene-based resin composition. On the other hand, in this embodiment, the thermoplastic resin layer 3 is a multilayered film composed of a polypropylene resin composition.

[0095] In the aforementioned first embodiment, the interlayer resin 4 is a polyethylene-based resin. On the othe...

Embodiment 1

[0117] (Process A) Manufacture of polypropylene spunbonded nonwoven fabric:

[0118] As the polypropylene-based resin, polypropylene resin (Y-2000GV: manufactured by Idemitsu Petrochemical Co., Ltd., NMR value (mmmm ratio) of 97%, isotactic pentad ratio of 99%) was used. method, manufactured a unit area weight of 40g / m 2 Polypropylene spunbonded nonwoven fabric. The polypropylene spun-bonded nonwoven fabric has a 10% modulus in the MD direction of 23N / 50mm at an ambient temperature of 100°C.

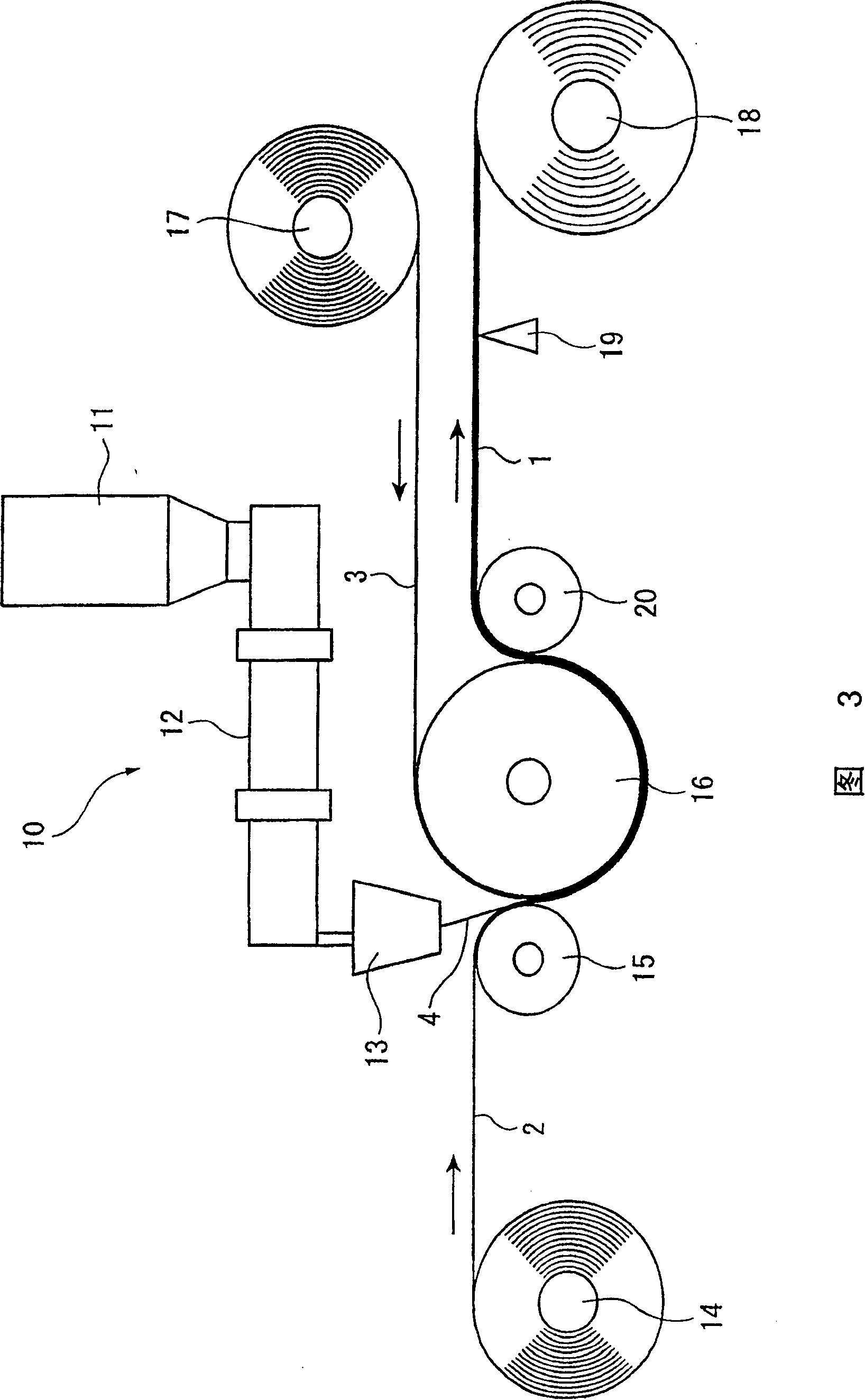

[0119] (Process B) Manufacture of laminated body:

[0120] For the polypropylene spun-bonded nonwoven fabric obtained in the aforementioned (step A), a polyethylene-vinyl acetate copolymer resin (Ultrasen 526: manufactured by Toray Co., Ltd., with a melting point of 97° C. and a vinyl acetate (VA) content of 7 %) is a thermoplastic resin layer, using the manufacturing device shown in Figure 4, extrusion lamination of polyethylene-vinyl acetate copolymer so that the thickness of the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com