Bending rotation device used for bending steel pipe

A bending and turning technology, which is applied in the field of bending devices, can solve the problems of hard corners, cracks, and affecting internal fluid circulation, etc., and achieve the effect of increasing the bending length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

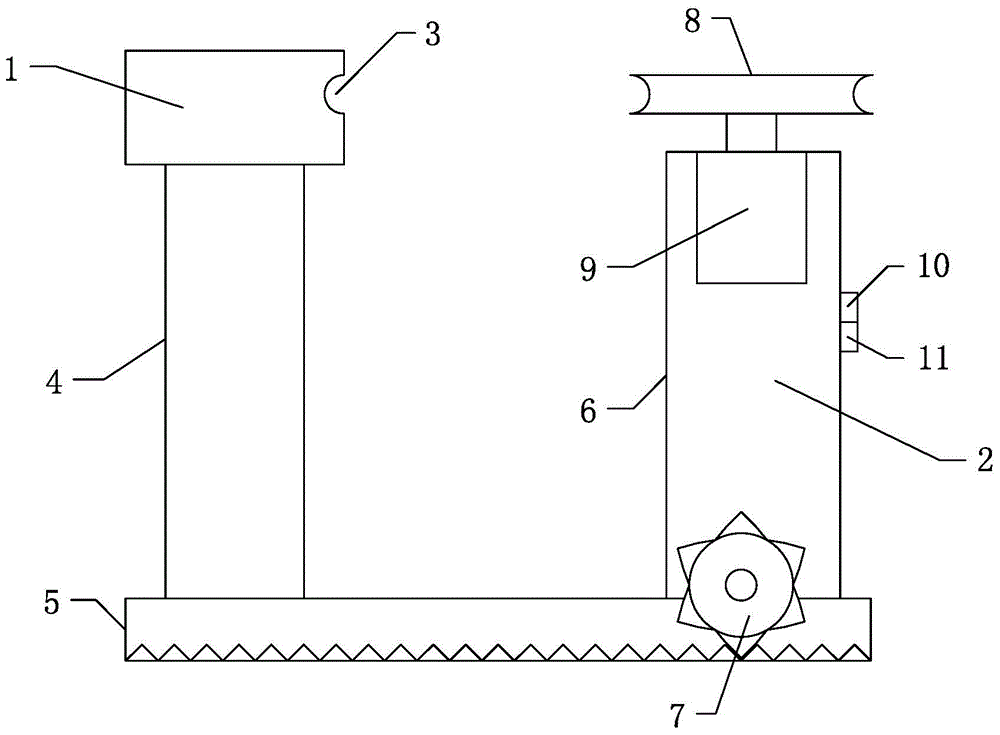

[0019] Such as figure 1 with figure 2 Shown is a bending device for bending steel pipes, a bending seat 1 and a bending wheel 2;

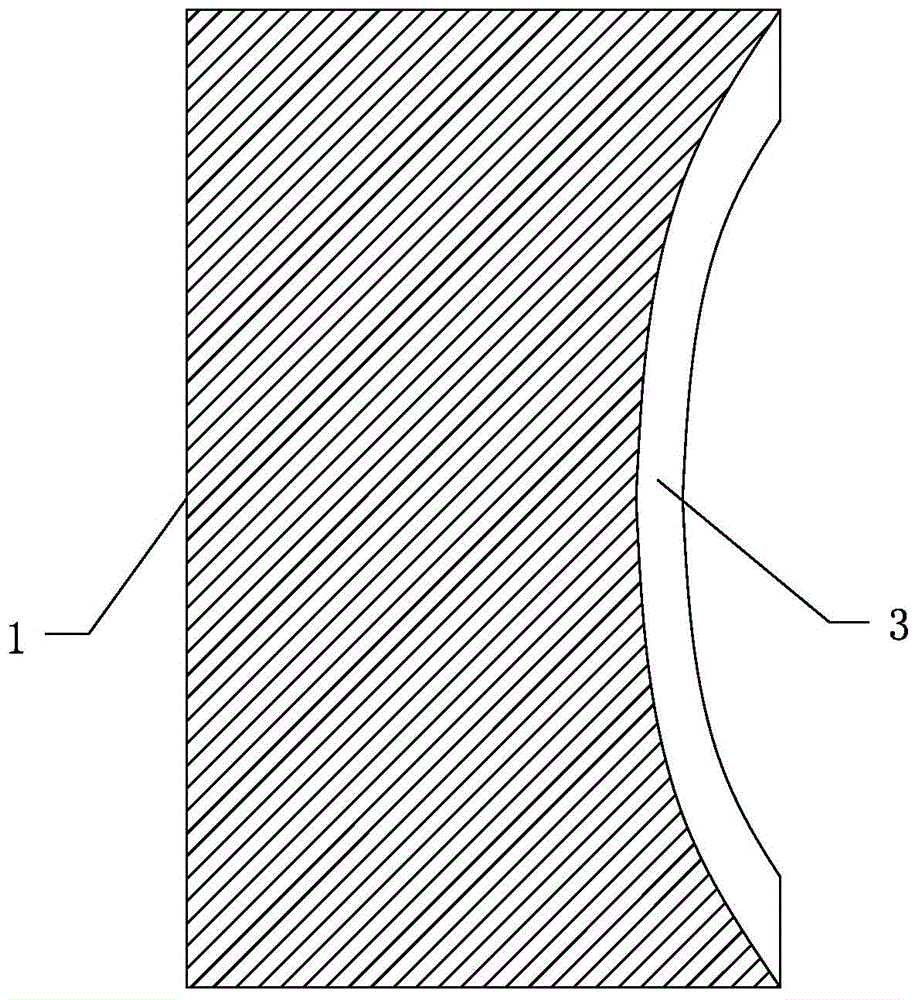

[0020] The surface of the bending seat 1 near the bending wheel 2 is processed with a bending groove 3 with a semicircular cross-section and an arc-shaped extending direction;

[0021] The bending seat 1 is fixed on the ground through the column 4;

[0022] The column 4 is laterally fixed with a guide rail 5, and the inner wall of the guide rail 5 is provided with teeth;

[0023] The bending wheel 2 includes: a supporting body frame 6, a travel gear 7 and a rotating wheel 8 fixed to the lower end of the supporting body frame 6 and meshed with the teeth on the inner wall of the guide rail 5;

[0024] The rotary wheel 8 is a disc with a semicircular cross-section processed radially on the circumferential side wall;

[0025] Adopt the present invention of above-mentioned technical scheme, at first put the straight pipe into the bending groove 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com