A deep cavity welding chopper for welding gold strips and its production process

A technology of gold strips and choppers, which is applied in the field of microelectronics, can solve problems such as unfavorable automatic high-speed welding operations, strong wire swing, and unstable welding wire direction, so as to avoid inaccurate welding, reduce the scrap rate, and avoid easy welding of gold strips. broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

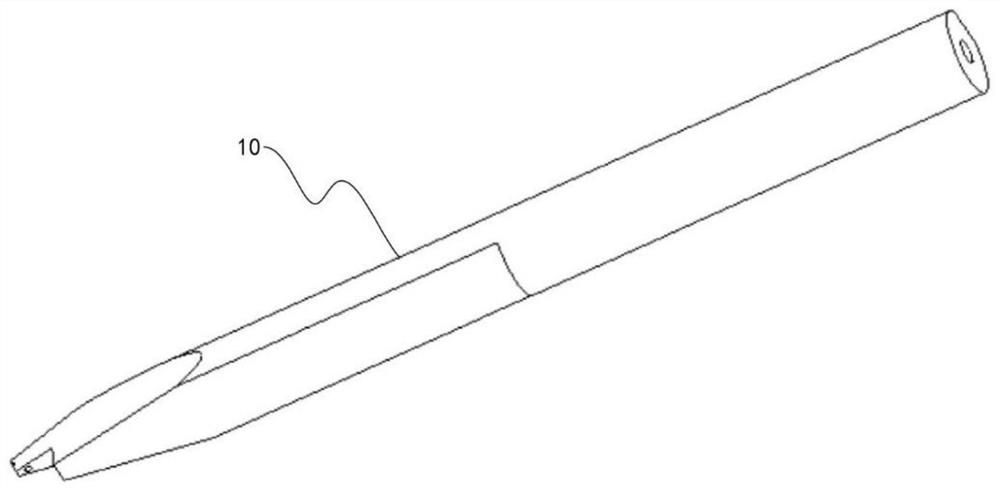

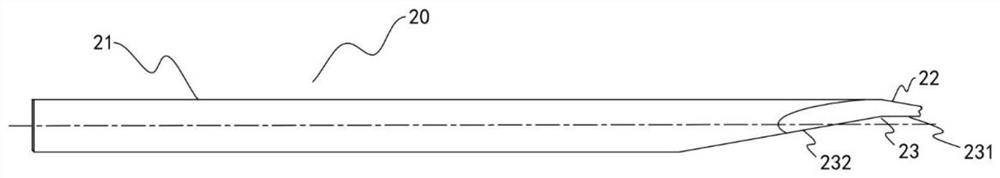

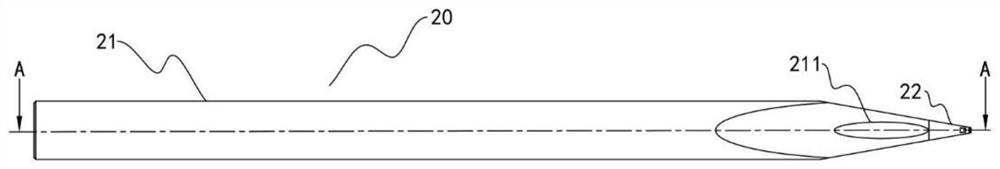

[0041] Such as Figure 2-Figure 5As shown, a deep-cavity welding capillary for welding gold strips includes a columnar capillary body 20, one end of the capillary body 20 is a gold strip guide 21, and the other end is a welding portion 22; the welding The portion 22 is in the shape of a truncated cone, its larger end face is close to the gold tape guide portion 21, and its smaller end face is away from the gold tape guide portion 21; a gap 23 is opened between the welding portion 22 and the gold tape guide portion 21, The notch 23 includes a flat cut surface 231 parallel to the axis of the riving knife main body 20 and an oblique cut surface 232 connected with the flat cut surface 231; One end is located at the smaller end surface of the welding part 22, and the other end of the flat cut surface 231 extends toward the gold strip guide part 21 and is connected with one end of the beveled cut surface 232, and the other end of the beveled cut surface 232 faces the chopper The ax...

Embodiment 2

[0043] In this embodiment, on the basis of Embodiment 1, the included angle between the chamfered surface 232 and the axis of the riving knife body 20 is 5°-15°.

Embodiment 3

[0045] In this embodiment, on the basis of Embodiment 1, the included angle between the axis where the gold band fixing hole 222 is located and the axis where the riving knife main body 20 is located is 30°-60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com