Processing method and steps of transmission shaft hole of base of super-large vertical lathe

A hole processing method and a transmission shaft technology, which are applied in the field of machine tools and equipment to achieve the effect of reducing processing costs, meeting precision requirements and processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

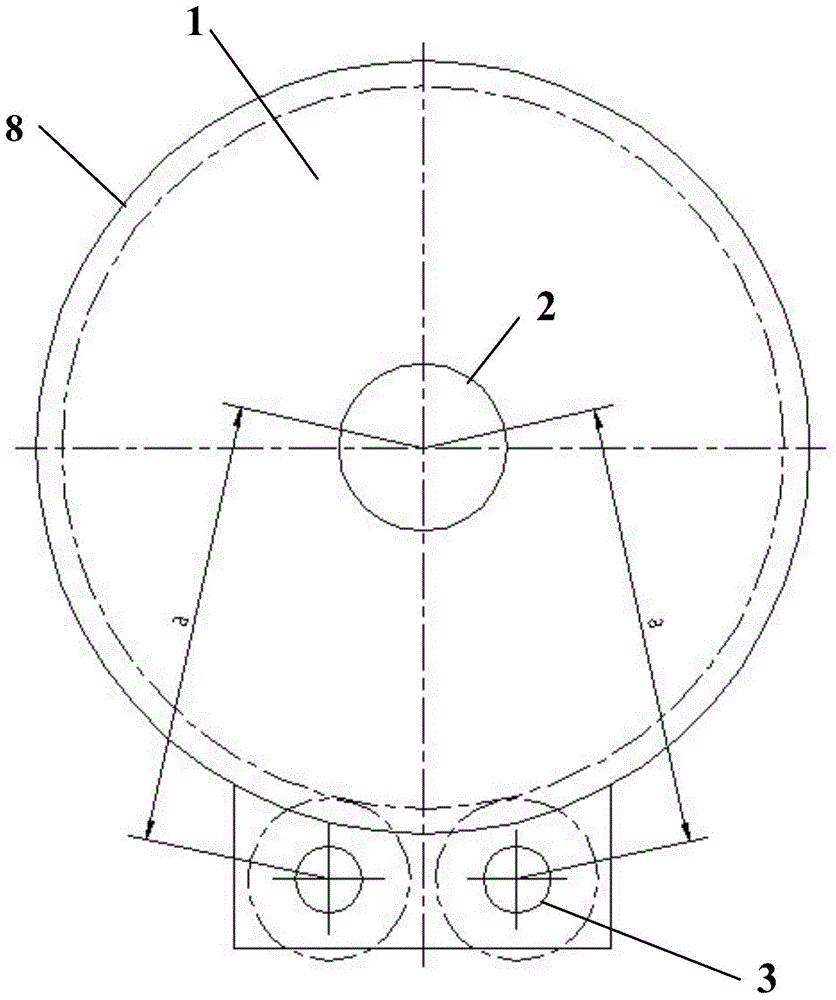

[0020] figure 1 What is shown is a schematic diagram of the structure of the base 1 and the relationship between the center hole 2 of the ring gear of the base 1 and the gear hole 3 of the transmission shaft.

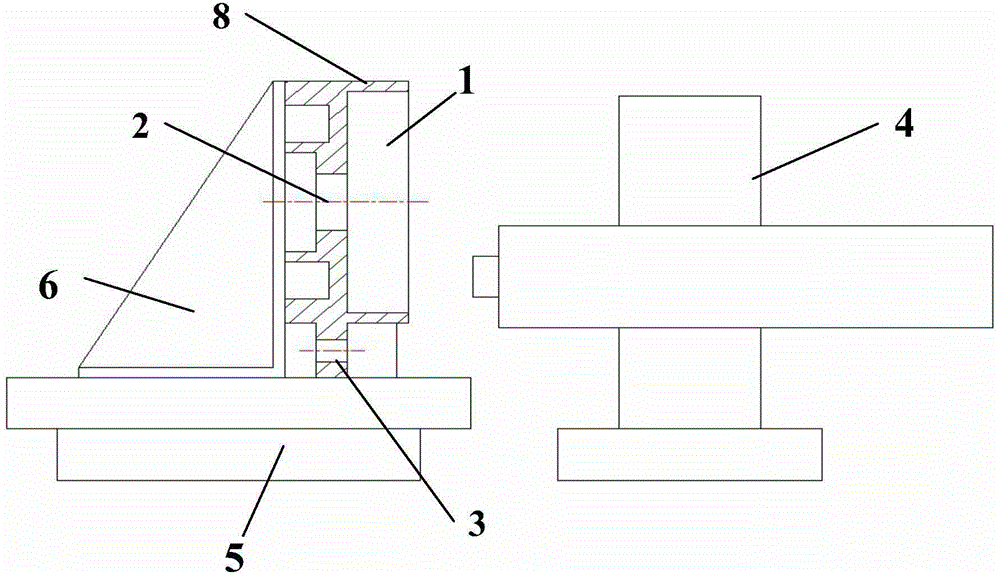

[0021] figure 2 It is a schematic diagram of processing the transmission shaft hole 3 of the base 1 of large, medium and small vertical lathes in the prior art. The processed vertical lathe base 1 is placed vertically on the fixed platform 5 of the ground milling and boring machine 4 , and the base 1 is supported by a support frame 6 .

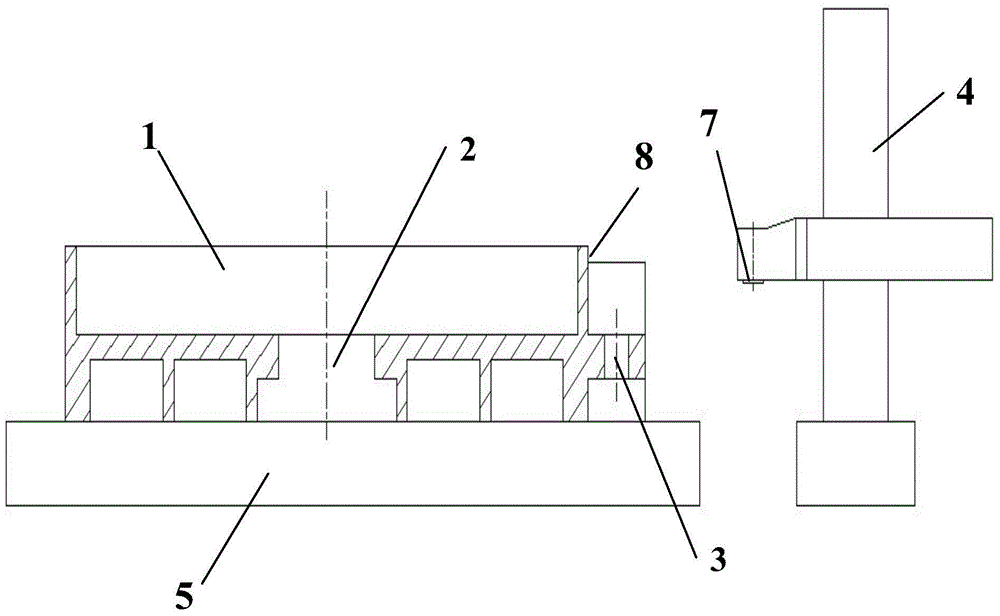

[0022] image 3 It is a schematic diagram of the processing and placing position of the ultra-large vertical lathe base in the present invention. The processed vertical lathe base 1 is placed flat on the fixed platform 5 of the ground milling and boring machine 4, and the transmission shaft hole 3 on the base 1 is close to the right-angle milling head attachment 7 at the spindle end of the floor milling and boring machine 4.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com