Fine positioning magnetic transfer table

A workbench and precise positioning technology, applied in the field of mold manufacturing and precision workpiece processing, can solve the problems of high price, unadjustable Z value height, limited travel distance of tool electrodes, etc., and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the invention will be described in detail below in conjunction with technical text and drawings.

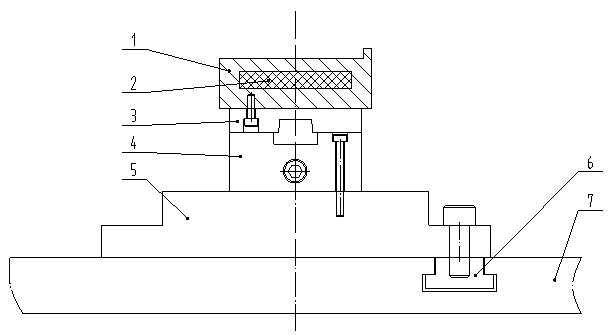

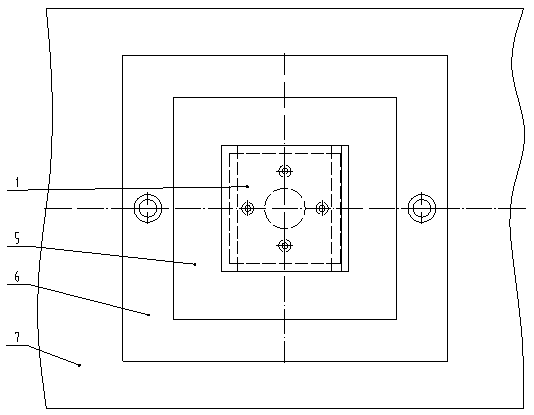

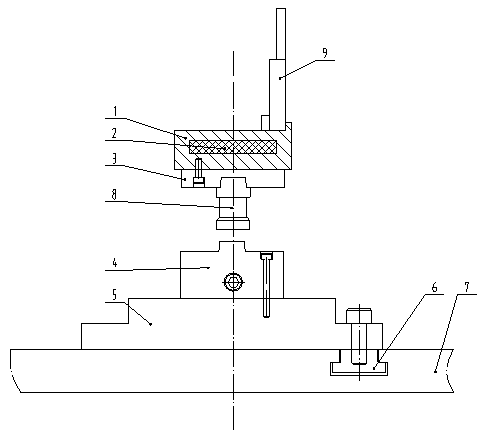

[0017] When assembling the precision-positioned magnetic conversion table, install the powerful magnet 2 in the through hole processed by the conversion table 1 to slide and fit, and contact the conversion table 1 with the chuck 3, and the bolt passes through the chuck 3 to change the table 1 Fixed on the chuck 3 (see Figure 4 ), the reference fixture 4 is in surface contact with the fixture connection plate 5, the bolt passes through the reference fixture 4 to fix it on the fixture connection plate 5, the reference fixture 4 and the fixture connection plate 5 as a whole are in surface contact with the EDM table 7 , The bolt passes through the fixture connecting plate 5 to thread it with the nut 6 set on the EDM table 7 and fix the reference fixture 4 and the fixture connecting plate 5 as a whole on the EDM table 7 (see figure 1 , 3 ), assemble and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com