Anti-rollover mechanism and system for truss type bridge inspection vehicle

A bridge maintenance vehicle and anti-tipping technology, which is applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve the problems of vehicle overturning, center of gravity exceeding the support surface, and vehicle center of gravity exceeding the support surface, etc., to achieve The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

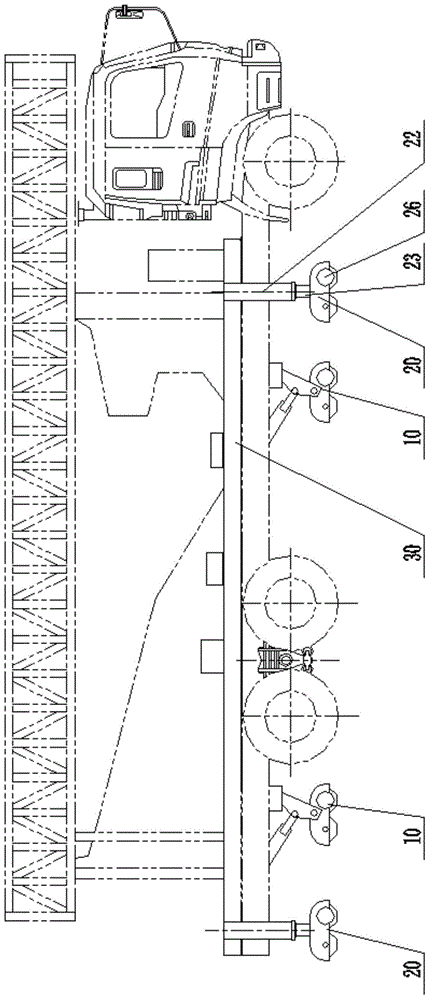

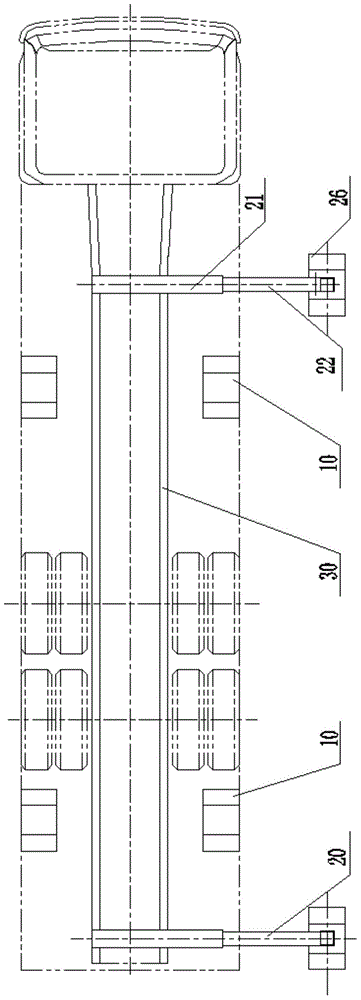

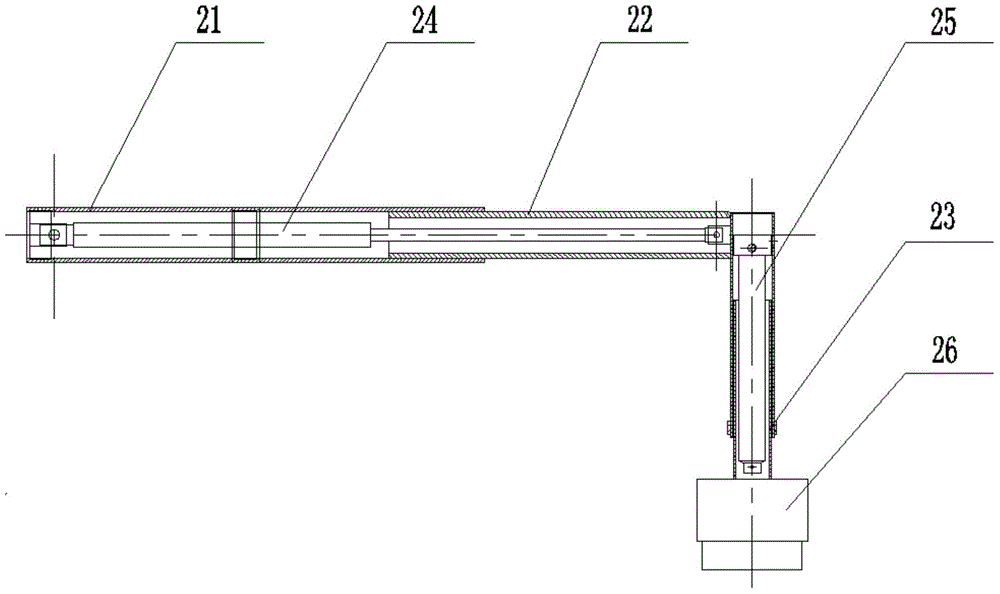

[0020] Such as Figure 1 to Figure 3 As shown, an anti-tipping mechanism of a truss-type bridge maintenance vehicle includes four sets of self-propelled support wheels 10 installed at the bottom of the sub-frame, and the mechanism also includes an auxiliary support set on the same side as the extending direction of the truss Wheel 20, the auxiliary support wheel 20 includes a horizontal outrigger box 21, an L-shaped telescopic outrigger 22 and a vertical outrigger 23 installed on the attached beam 30 of the upper vehicle, and one end of the L-shaped telescopic outrigger 22 is sleeved on the horizontal outrigger Inside the leg box 21, the vertical support leg 23 is set inside the other end of the L-shaped telescopic support leg 22; one end of the horizontal telescopic oil cylinder 24 is connected in the horizontal support leg box 21, and the other end is connected in the L-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com