Double-layer cast-in-situ beam support construction method adopting sequence from upper layer to lower layer

A construction method, the technology of first up and then down, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of foundation settlement and beam deformation, cumbersome installation and removal of brackets, and long construction period, etc., to avoid The effect of mismatching support stiffness and inconsistent foundation deformation, ensuring overall stability and structural safety, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

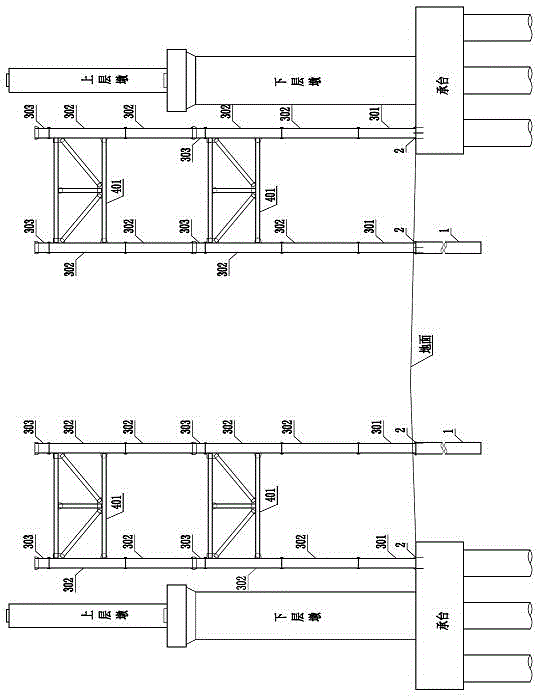

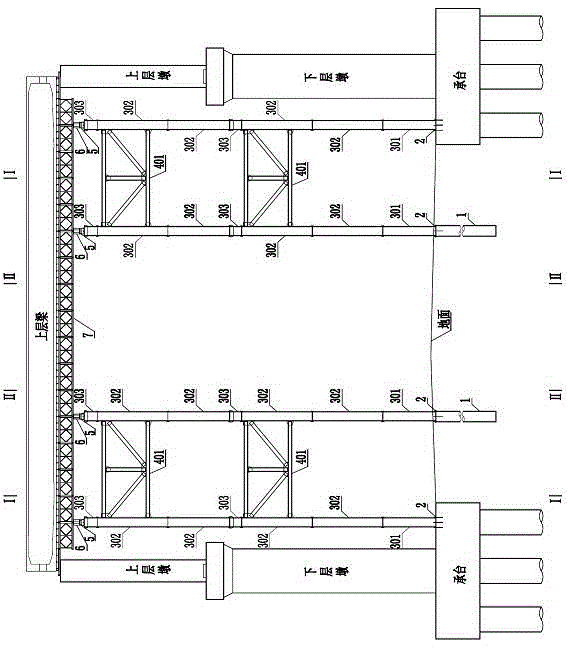

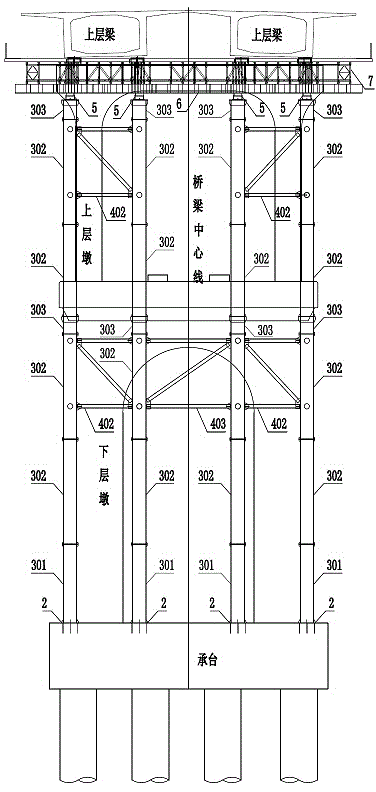

[0040] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0041] The construction equipment of the present invention consists of a support foundation bored pile 1, a support steel pipe embedded part 2, a support steel pipe 300, a connecting system 400, a sand cylinder 5, a column top distribution beam 6, a Bailey beam 7, a lowering device 800, and a crane 9 composition.

[0042] Bored piles for support foundation 1: Bored piles 20cm larger in diameter than steel pipes are used for mid-span support foundation treatment.

[0043] Support steel pipe embedded parts 2: During the concrete construction of the pier side cap and support foundation bored pile concrete, the support steel pipe embedded parts are buried on the top surface.

[0044] Support steel pipe 300: According to the total length of the support steel pipe in the design drawing, reasonably divide the support steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com