Construction method for water jet cutter Larsen steel sheet pile

A Larsen steel sheet pile and construction method technology, which is applied to sheet pile walls, excavation, foundation structure engineering, etc., can solve problems such as increased project costs, difficulty in driving, and broken Larsen steel sheet pile locks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

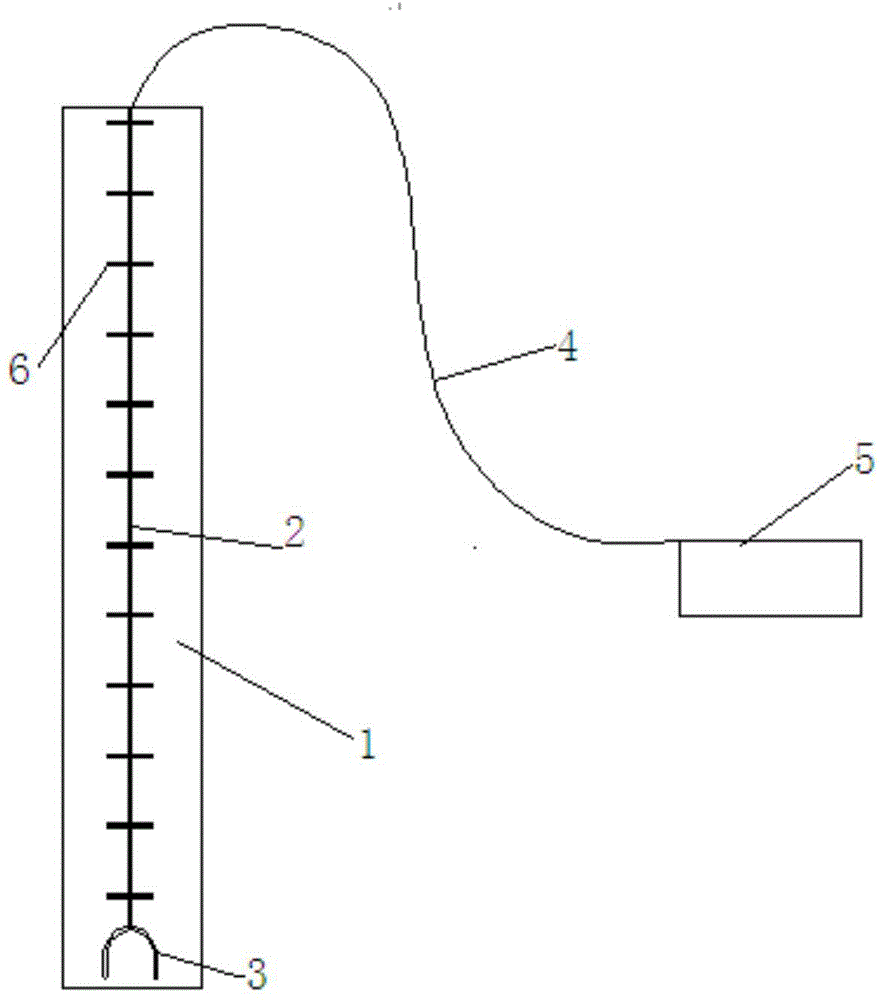

[0024] Referring to the accompanying drawings, the construction method of water-jet Larsen steel sheet piles includes the following construction steps:

[0025] 1) Before construction, check the total station and level used for Larsen pile construction; and check the benchmark points for measurement and stakeout;

[0026] 2) Measurement and setting out, according to the measurement results of the re-test and approval, use the total station to measure the plane position and size of the cofferdam, and control the verticality of the measurement during the process of inserting and driving the steel sheet piles to correct the deviation in time;

[0027] 3) Install the guide frame. According to the construction drawings, install the guide frame according to the design position. The guide frame is mainly composed of double-jointed 40b I-steel channel steel assembled and welded, and connected by No. 16 channel steel to form a frame-type guide device;

[0028] 4) Production of water-je...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com