Liquid ammonia cooling system for paraffin production line

A cooling system and production line technology, applied in the petroleum industry, household refrigeration equipment, mineral wax recovery/refining, etc., can solve the problems of low production efficiency and low cooling effect of production lines, and achieve the effect of avoiding mutual interference and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purposes, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the embodiments of the present invention:

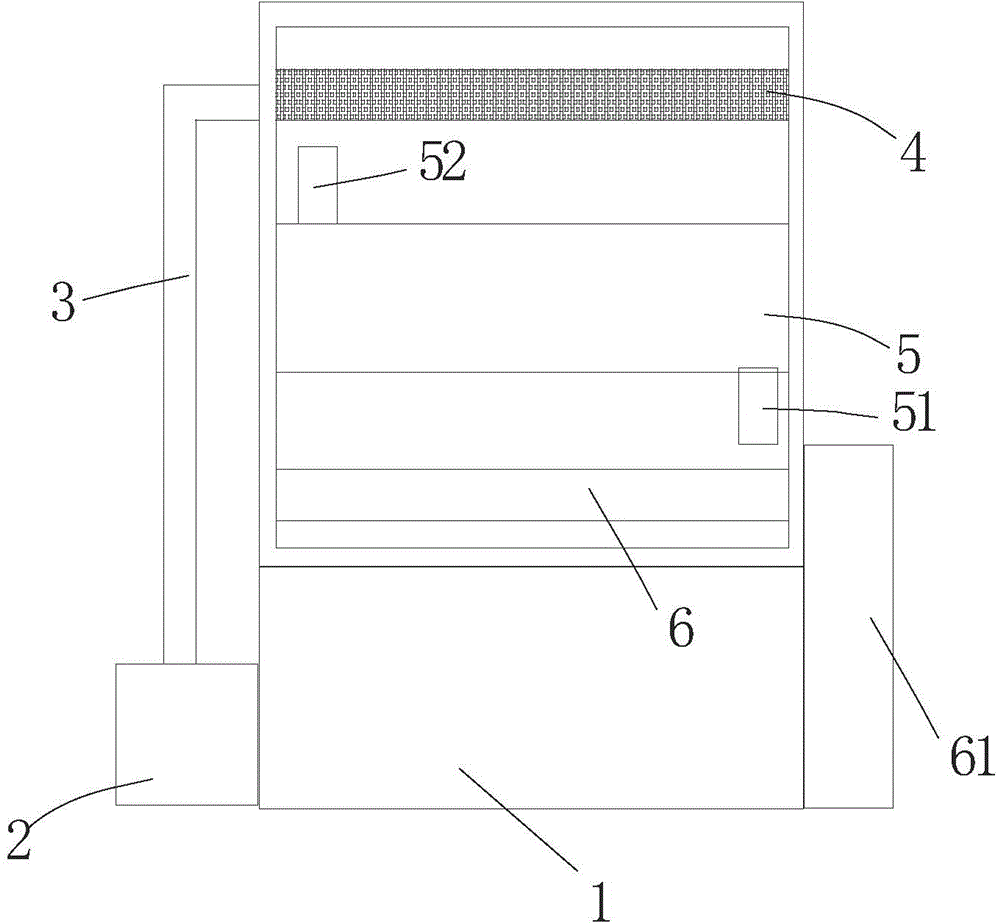

[0013] like figure 1 and figure 2 Shown: a liquid ammonia cooling system for a paraffin production line, mainly: an external frame 1, a spray pipeline 4 above the interior of the external frame 1 is fixed, a medium cooling pipeline 5 located below the spray pipeline 4, a paraffin production line The high-temperature liquid ammonia produced enters the medium cooling line 5 through the inlet 51 arranged below the medium cooling line 5 and is output from the outlet 52 arranged above the medium cooling line 5;

[0014] During the process of passing through the medium cooling pipeline 5, the cooling water sprayed from the spray pipeline 4 is received for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com