Semiconductor module device, production method thereof, display device and display panel

A technology for semiconductors and flexible substrates, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., and can solve problems such as increasing the number of components and increasing the weight of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] (Embodiment 1)

[0036] Below, use Figure 1 to Figure 6 A heat dissipation structure of a semiconductor module device according to an embodiment of the present invention will be described.

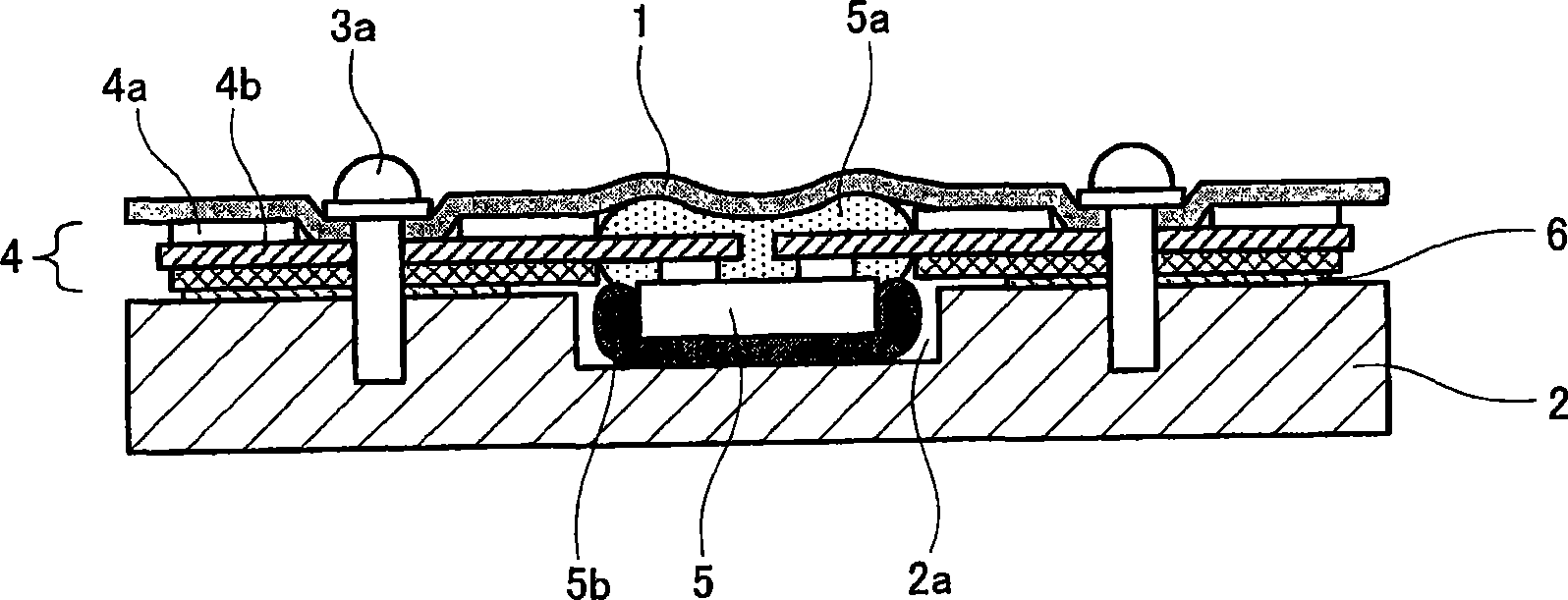

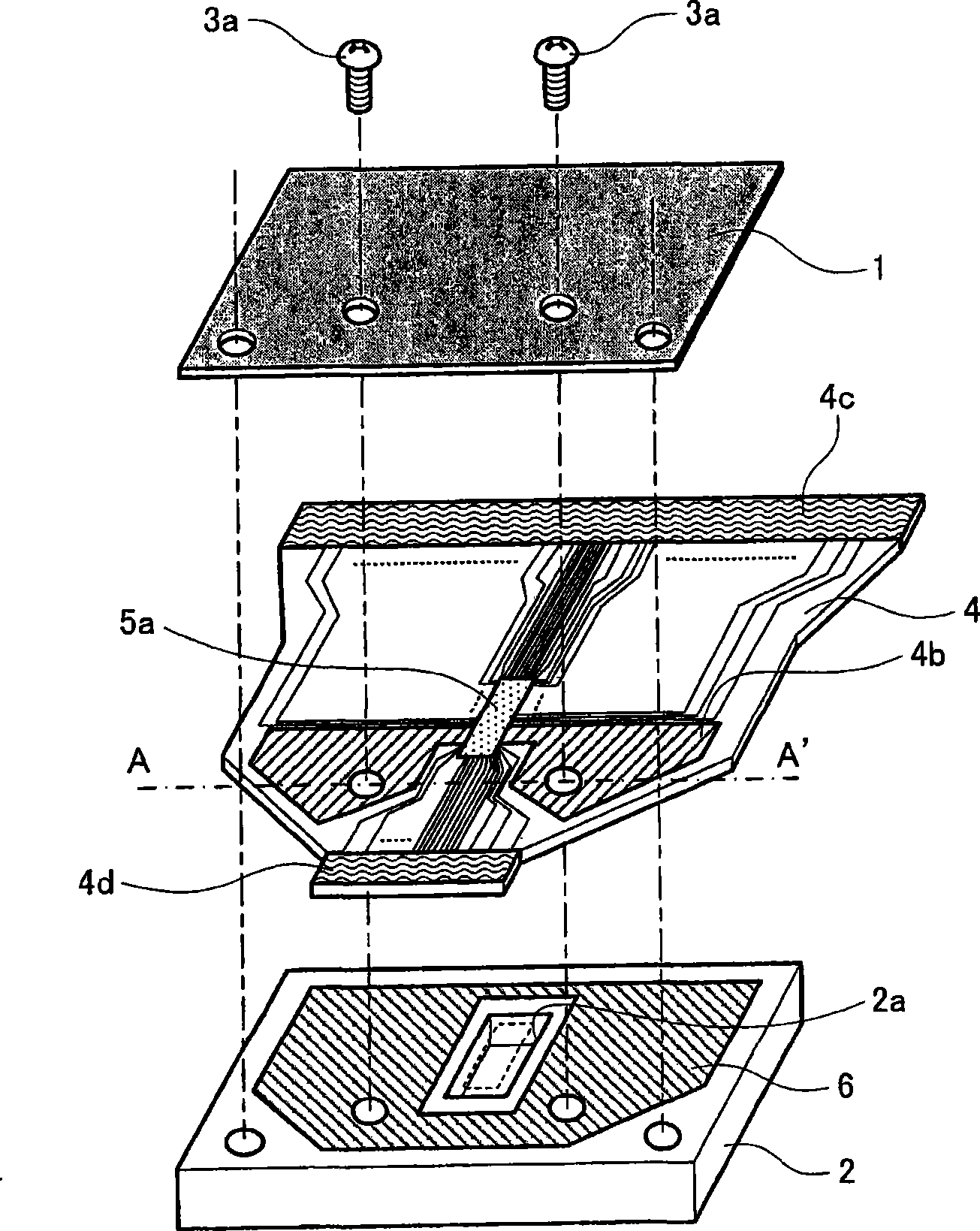

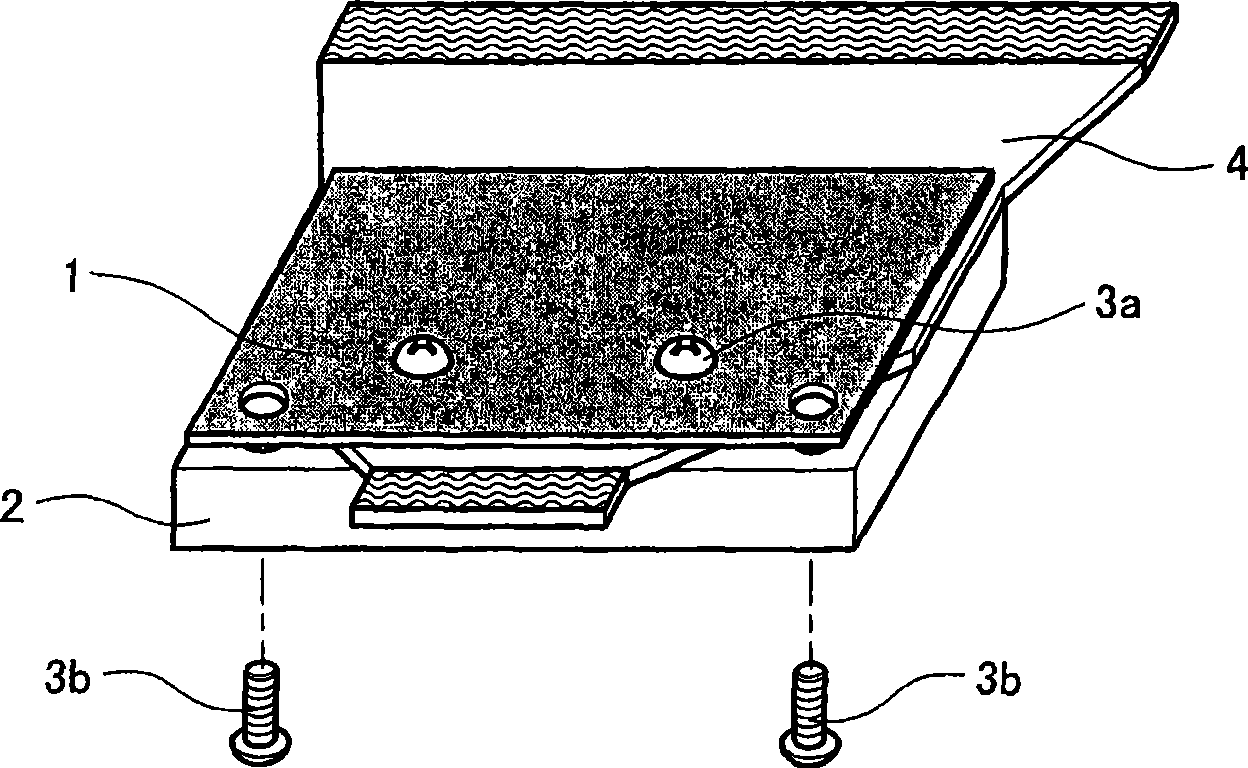

[0037] figure 1 is a cross-sectional view showing the structure of the semiconductor module device according to Embodiment 1, and figure 2 Sectional view of part A-A' when assembled from the exploded view shown. figure 2 It is an exploded perspective view showing the structure of the semiconductor module device according to the first embodiment. image 3 It is a perspective view of an assembled appearance of the semiconductor module device according to the first embodiment. Figure 4 It is an enlarged view showing a main portion of the chassis portion of the flat display panel according to Embodiment 1, and is an enlarged perspective view of a part of the chassis supporting the flat display panel of the flat display device. Figure 5 It is a perspective view showing a state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com