Magnetic induction variable-speed switch device

A switch device and magnetic induction technology, which is applied in permanent magnet contact switch, magnetic field/electric field switch, electric switch, etc., can solve the problems that the explosion-proof standard cannot be achieved, the motor cannot realize stepless speed change and reverse function, and achieve safety The effect of high coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

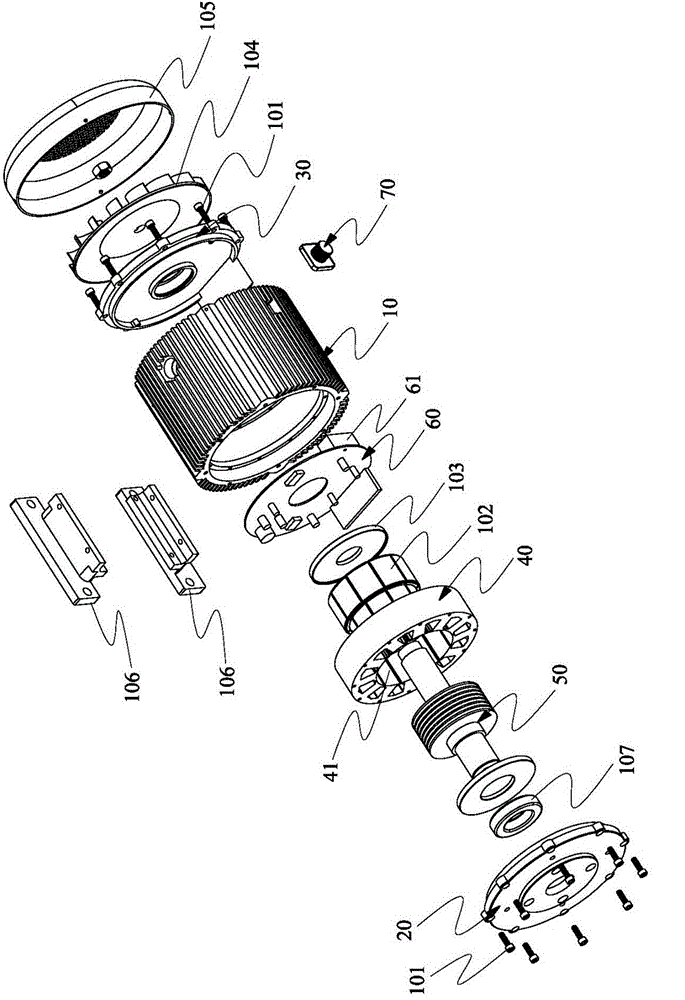

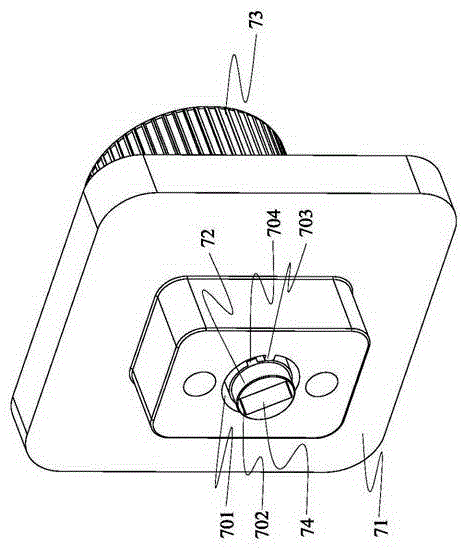

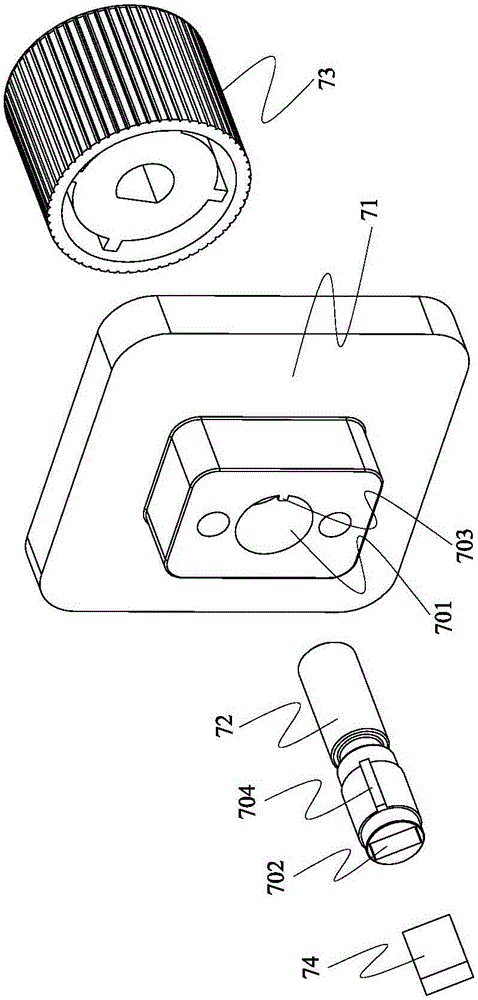

[0031] Please refer to figure 1 and Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, including motor housing 10, motor front cover 20, motor rear cover 30, stator 40, rotor 50, frequency conversion circuit controller 60 and magnetic induction Control switch 70 .

[0032] Wherein, the motor front cover 20 and the motor rear cover 30 are respectively fixed on the front end and the rear end of the motor housing 10, and the motor housing 10, the motor front cover 20 and the motor rear cover 30 jointly form an accommodating cavity (not shown in the figure), in this embodiment, the motor front cover 20 and the motor rear cover 30 are disc-shaped, the motor housing 10 is hollow cylindrical, the motor front cover 20 and the motor rear cover 30 All are fixedly connected with the motor housing 10 through eight bolts 101, and have simple structure and convenient assembly.

[0033] Both the stator 40 and the frequency conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com