Insulating ratchet wrench

A ratchet wrench and wrench technology, applied in the field of wrenches, can solve the problems of dangerous work, lack of insulation, and poor idling, and achieve the effects of avoiding damage, prolonging service life, and avoiding concentrated stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

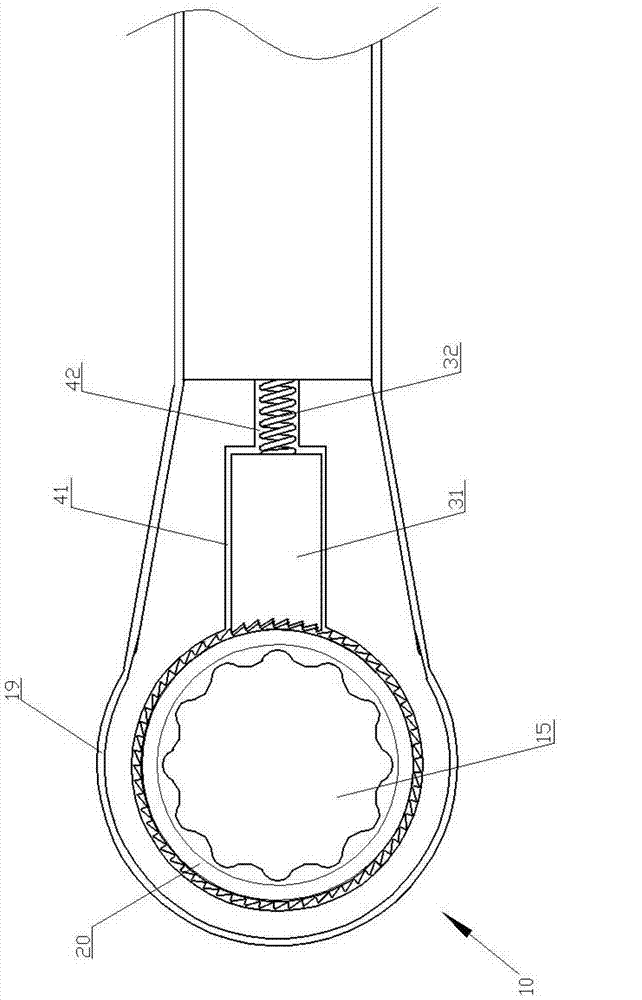

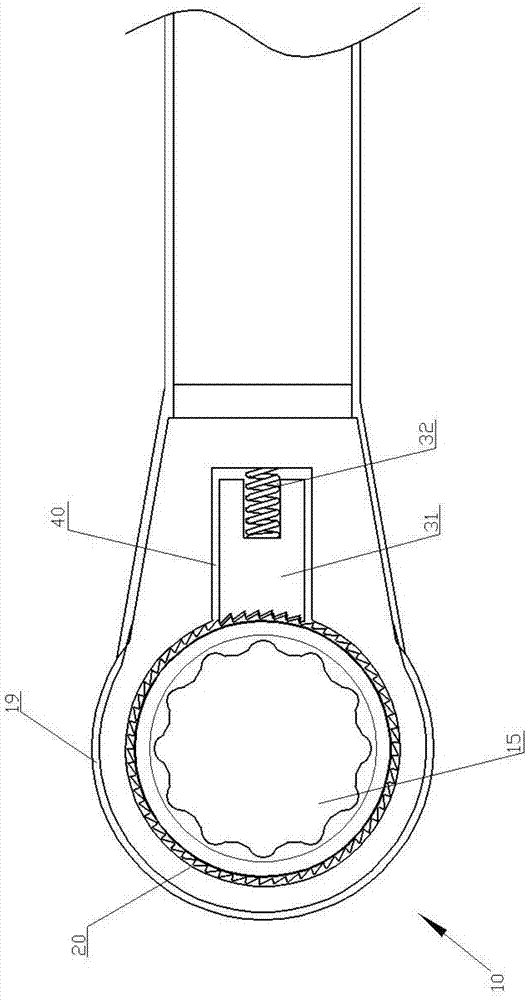

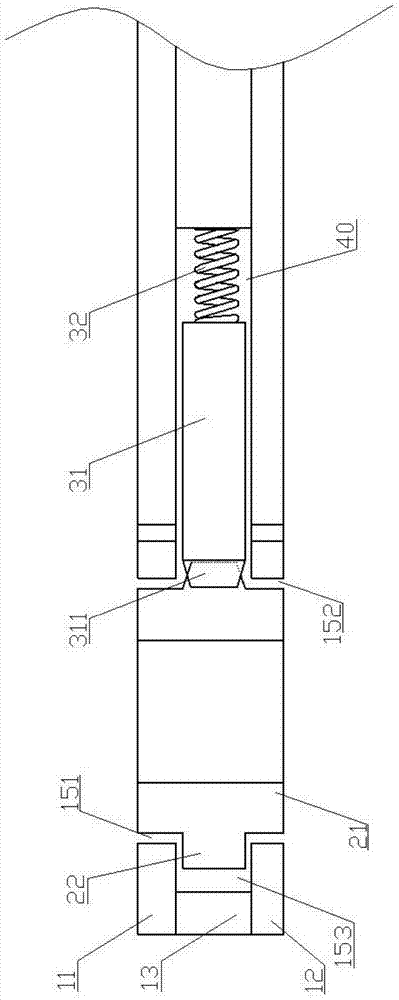

[0019] Insulated ratchet wrench disclosed by the present invention, such as figure 1 As shown, it includes a wrench body 10, a ratchet 20, and a locking mechanism. Wherein, the wrench body 10 is provided with an annular through hole 15, which can penetrate through the wrench body 10 or not penetrate, and the function of the through hole 15 is to trap the nut to be operated. In addition, the ratchet 20 is embedded in the through hole 15 and rotates around the axial direction of the through hole. In other words, the ratchet 20 is placed in the through hole 15 and cannot be separated from the through hole 15, but can rotate freely therein; The body 10 is also provided with a groove body 40 for setting the locking mechanism. Specifically, the locking mechanism includes a locking block 31 and a spring 32. One end of the spring 32 abuts against one end of the lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com