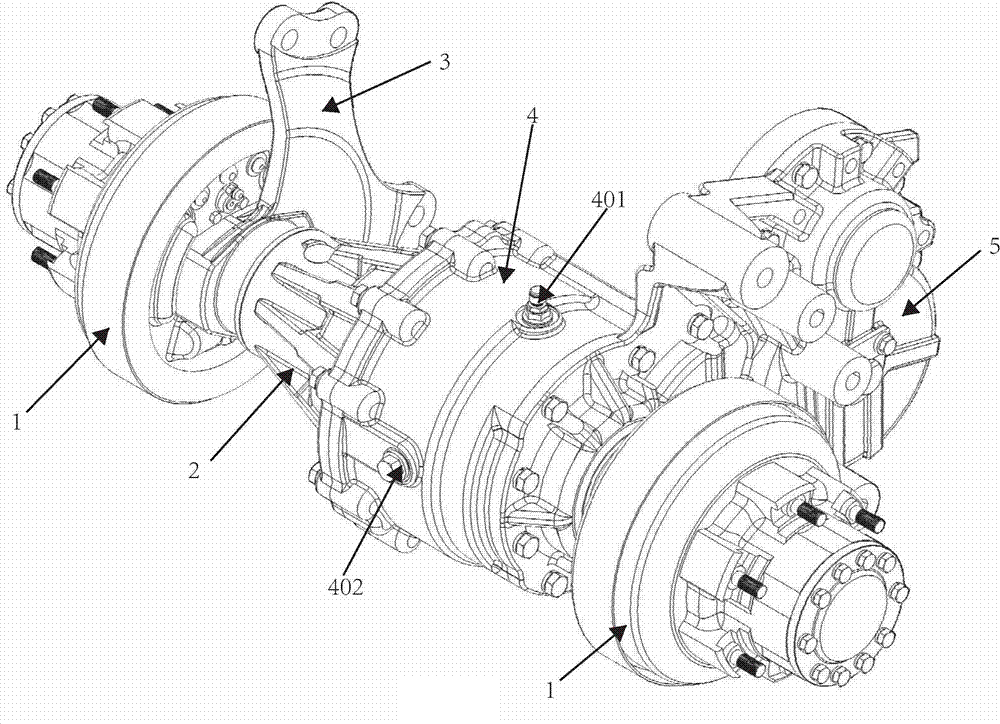

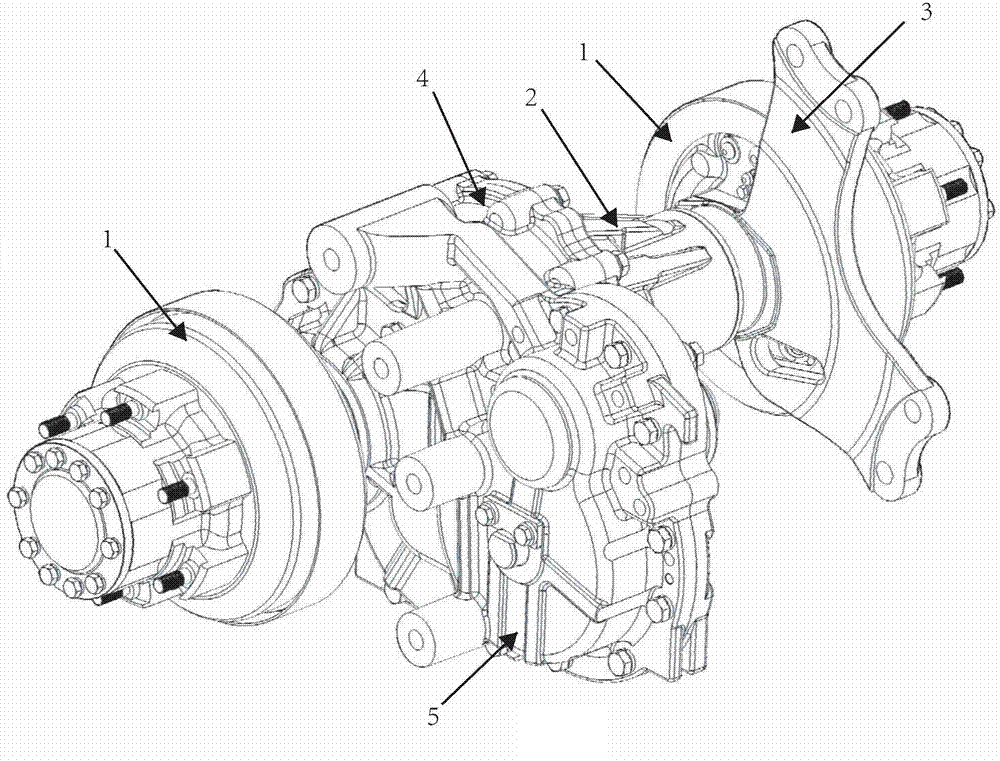

Electric fork-lift truck, axle case and reducer casing cover thereof

A technology of electric forklift and box cover, applied in the direction of axles, wheels, vehicle parts, etc., to achieve the effects of improving connection reliability, small size, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

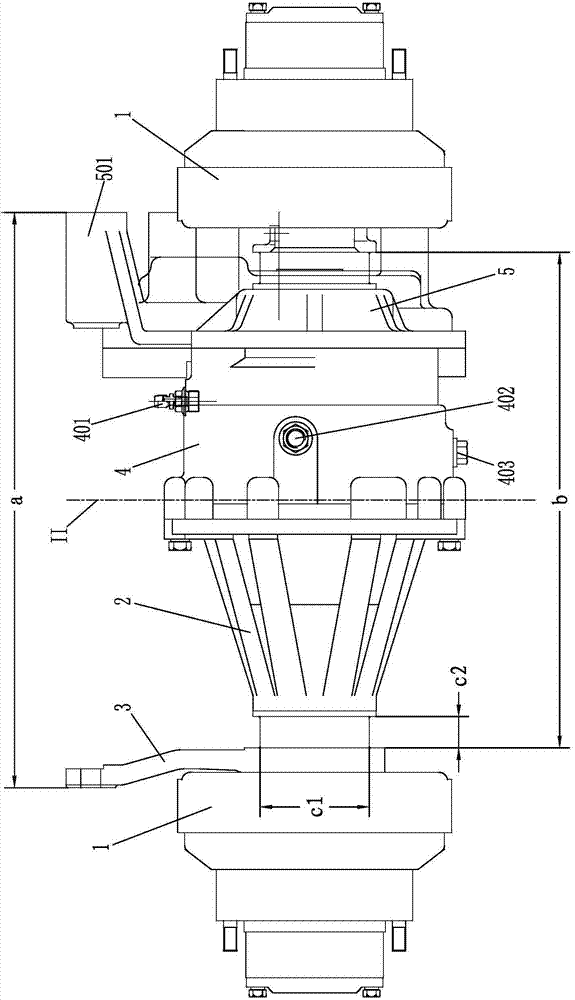

[0047] Such as Figure 14As shown, a second support plate 51 is provided on the outer side of the reduction box cover 5, and the second support plate 51 includes a sleeve portion for being sleeved on the first axle arm 11 and a plate portion for connecting the forklift frame. The second annular mounting groove is provided on the outer circumference of the cylinder, the plate is formed with a reinforced bend, and the fifth connection hole 5101, the sixth connection hole 5102, the seventh connection hole 5103 and the eighth connection hole 5104 are provided on the plate The plate portion is provided with a ninth connecting hole 5105 between the fifth connecting hole 5101 and the sixth connecting hole 5102, and the second support plate 51 is fixedly connected to the reduction box cover 5 through connecting bolts passing through the ninth connecting hole 5105. Wherein, the axis of the transmission shaft 8 is parallel to the axis of the driving half shaft 6 and both are located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com