Core slot for core box

A core tank and core box technology, applied to rigid containers, bottle/can parts, containers, etc., can solve problems such as careless operation, damage, and unreasonable structure, so as to reduce the occupied space and avoid idleness and waste , Easy to use and carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

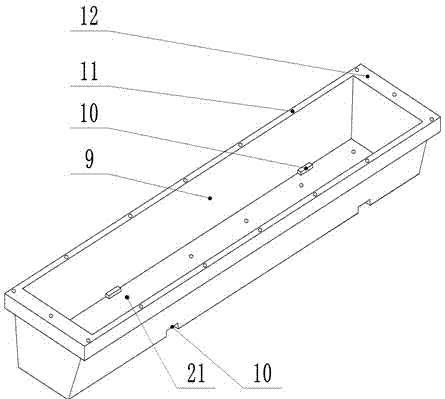

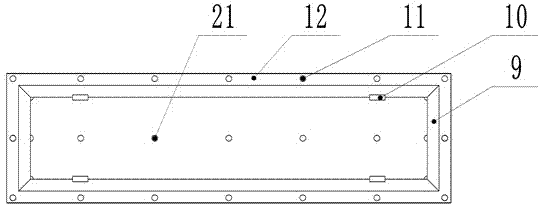

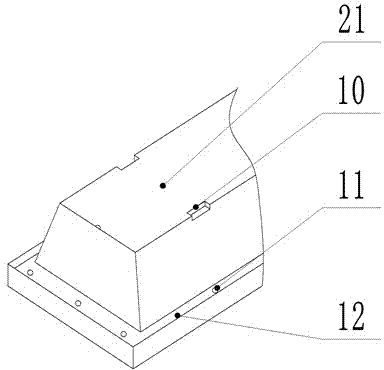

[0036] like Figure 1 to Figure 11 As shown, a core tank for a core box is characterized in that: the core tank 9 includes a bottom tank with the notch of the bottom containing the core upward and a cover tank with the closed top of the notch downward, and the bottom of the bottom tank and the cover The top of the tank is provided with a plurality of drain holes 21 . The bottom groove and the cover groove are composed of at least one square funnel-shaped groove whose walls around the groove shrink inward. The bottom of the funnel-shaped groove of the bottom groove is provided with a card code positioning protrusion 10 cooperating with the card code locator. The bottom of the funnel-shaped groove of the bottom groove and the cover groove are all provided with card code positioning protrusions 10 that cooperate with the card code locator. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com