Rotating rail replacing device and construction method thereof

An implementation method and the technology of the rotating frame, which is applied in the direction of transportation, packaging, elevators, etc., can solve the problems such as the inability to change the track, achieve the effect of fast and reliable track change, improve utilization rate, and ensure connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

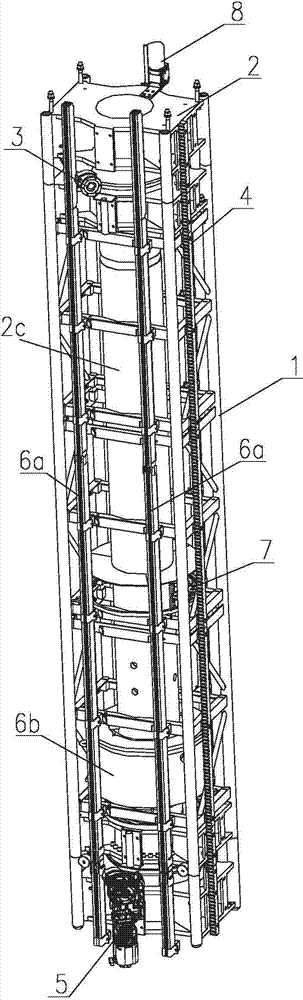

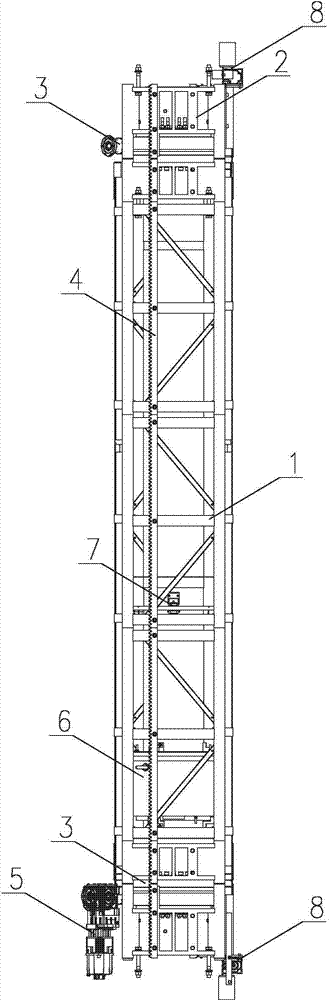

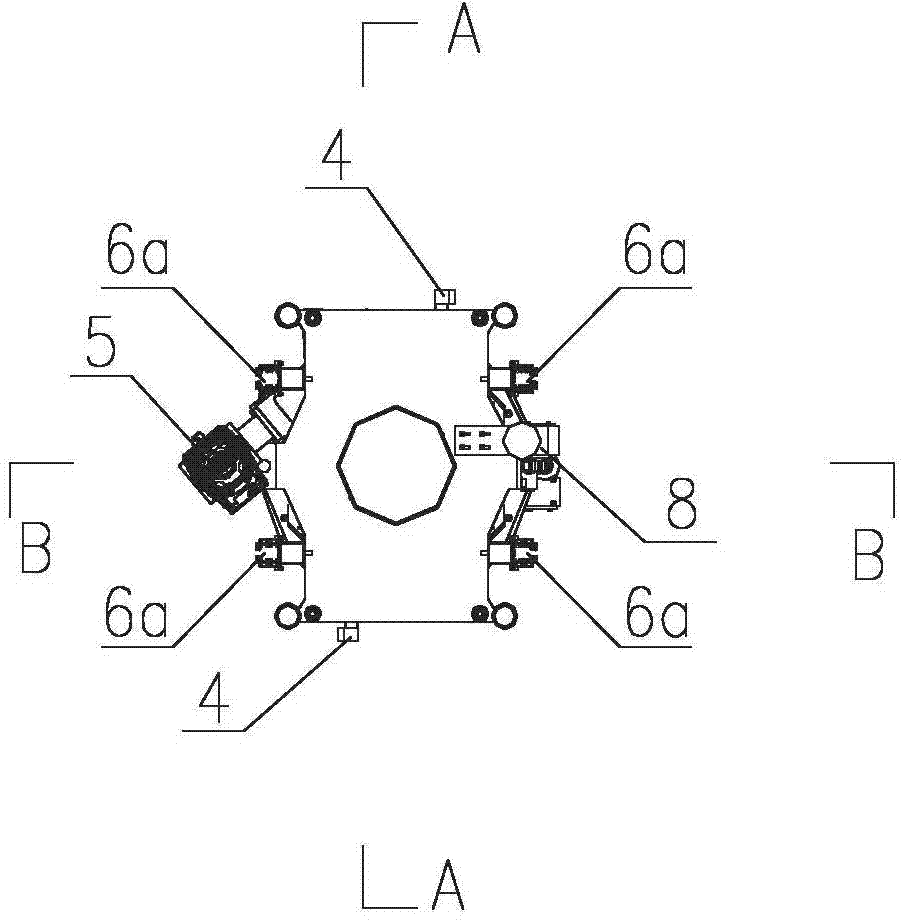

[0041] A method for implementing a rotary rail changing device, comprising the following steps:

[0042] S1. Install and fix the rotary rail changing device at the position where the track needs to be changed, turn on the power supply, and complete the mechanical and electrical debugging;

[0043] S2. When the ladder cage running along the track needs to change the track, it runs to the rotating frame and is connected to it for fixation;

[0044] S3. Unlock the rotating frame body and the fixed frame body (in this embodiment, the latch is driven to pull out the latch);

[0045] S4. The ladder cage rotates 180 degrees around the rotation axis together with the rotating frame body (in this embodiment, the rotating drive mechanism drives the bearing to drive the rotating frame body to rotate, the angle sensor is used to control the rotation angle, and the power supply device is used to ensure continuous power during the rotation process, intelligent And accurately realize the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com