Solid-propellant rocket engine capable of being ignited at tail

A rocket motor, solid fuel technology, applied in rocket motor devices, machines/engines, mechanical equipment, etc., can solve the problems of difficult to achieve ignition and combustion, unstable working performance of rocket motors, difficult to ignite, etc., to achieve convenient implementation, structure Simple, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

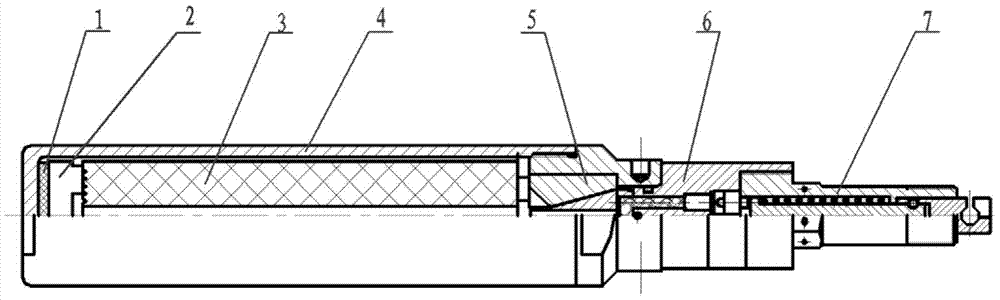

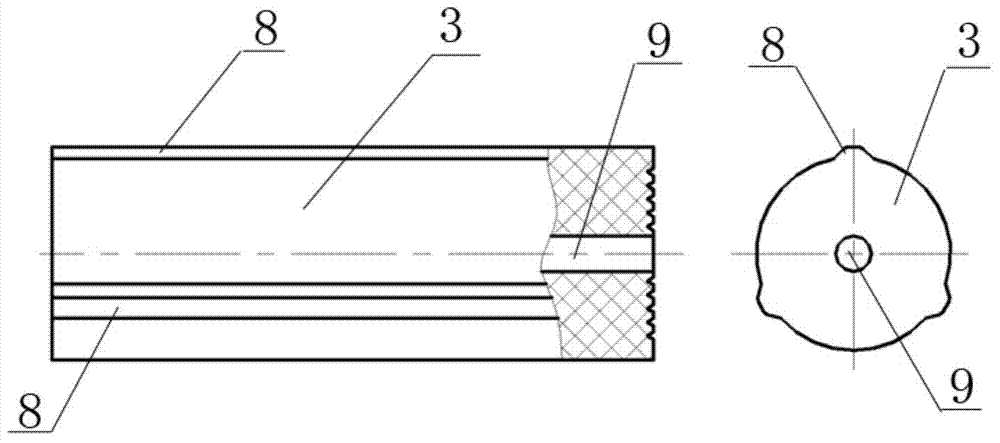

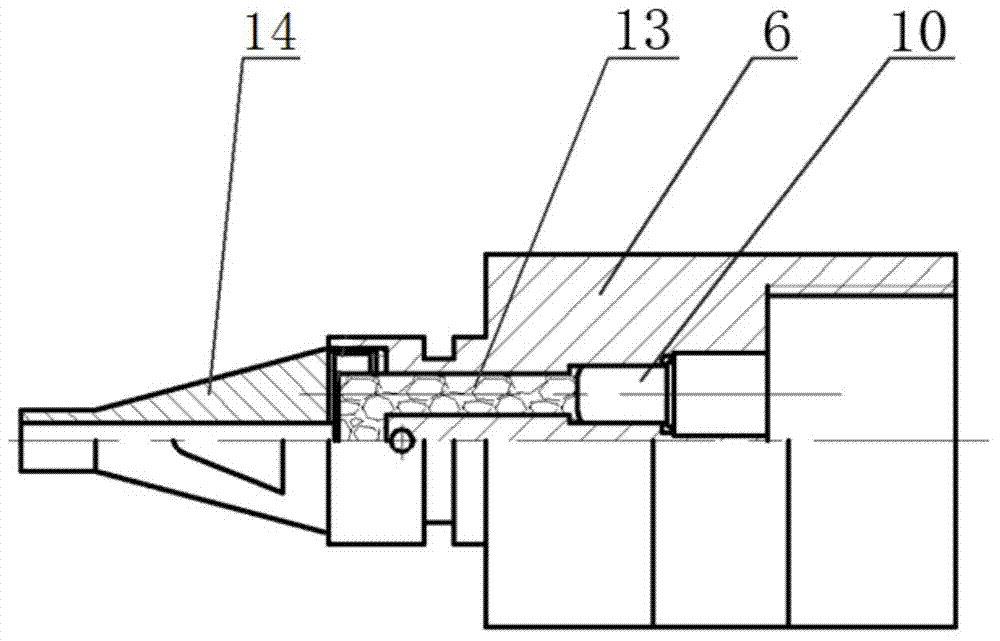

[0019] Such as figure 1 The shown embodiment of the solid fuel rocket motor capable of tail ignition of the present invention includes a combustion chamber 4, a nozzle assembly 5 and a solid fuel 3, the nozzle assembly 5 is arranged at the tail end of the combustion chamber 4, and the solid fuel 3 is arranged on the combustion chamber. In the chamber 4; it is characterized in that: the solid fuel rocket engine also includes an ignition box 2, an ignition tool 6 and its firing mechanism 7, the ignition box 2 is arranged at the front end of the solid fuel in the combustion chamber, and the ignition tool 6 is arranged at the nozzle assembly 5 end of . A buffer pad 1 is provided between the front end of the combustion chamber and the ignition box to compensate for changes in the length of the solid fuel 3 due to temperature.

[0020] The present invention is a two-stage ignition mode composed of an igniter 6 installed at the tail of the rocket and an ignition box installed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com