A rotor rubbing fault detection method and system based on matching demodulation transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

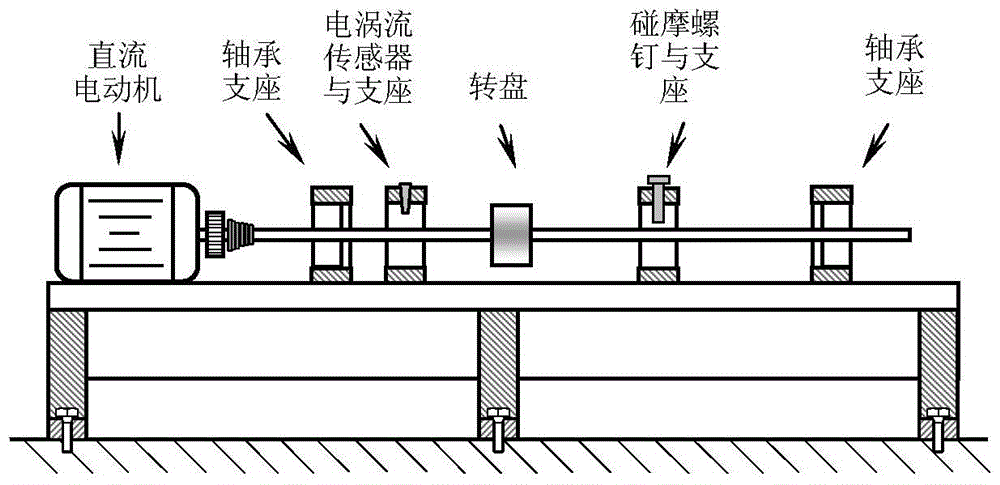

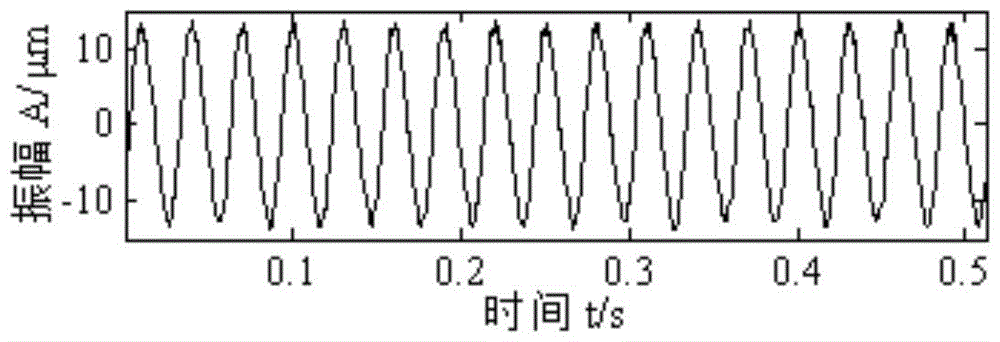

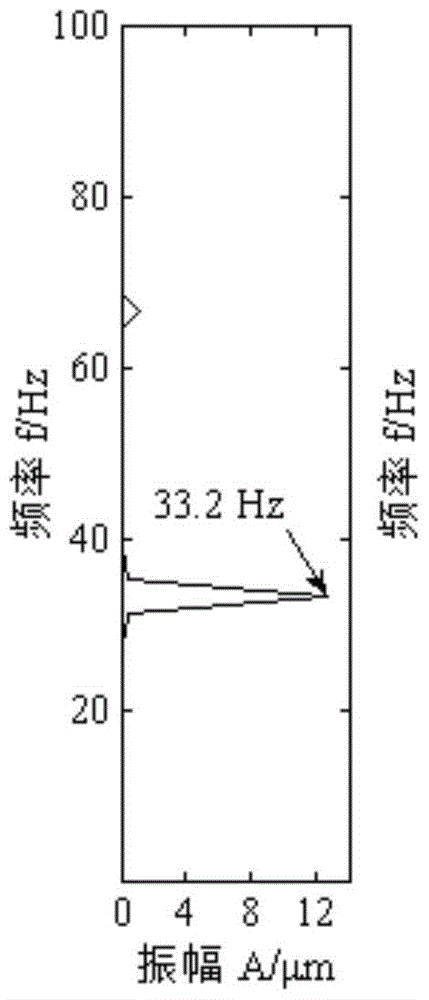

[0026] In a basic embodiment, the present invention provides a rotor rubbing fault detection method based on matched demodulation transformation, the method uses a matched demodulation algorithm to obtain an estimated value of instantaneous frequency; calculating the estimated value of instantaneous frequency The spectrum of the oscillating part, if f r is the rotation frequency of the rotor system, if the maximum spectral peak of the spectrum is located at 0.99f r ~1.01f r range and the amplitude exceeds 2% of the rotational frequency, it can be determined that the rotor system has a rubbing fault; otherwise, it is determined that the rotor system does not have a rubbing fault;

[0027] The matching demodulation algorithm uses the parameterized model of the instantaneous frequency of the vibration signal of the rotor system to approach the ridge line of the rotational frequency of the rotor system, and then identifies the parameters of the parameterized model, thereby obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com