Pull-out guide

A technology for pulling out guides and components, applied to furniture parts, household heating, bearings, etc., can solve problems such as cancellation, large tolerance, fuzzy determination of clamping force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

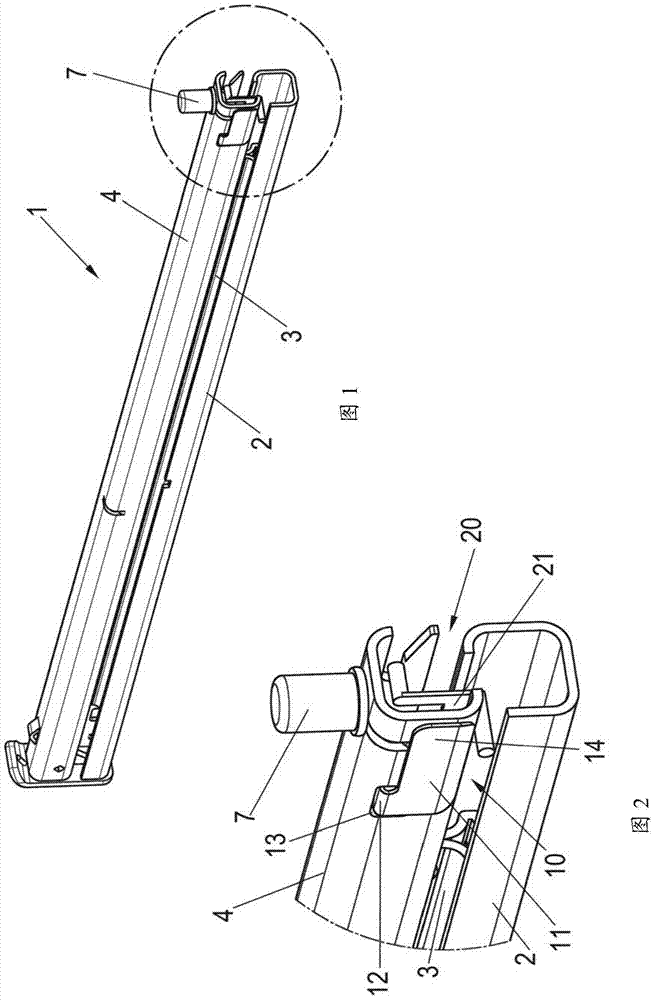

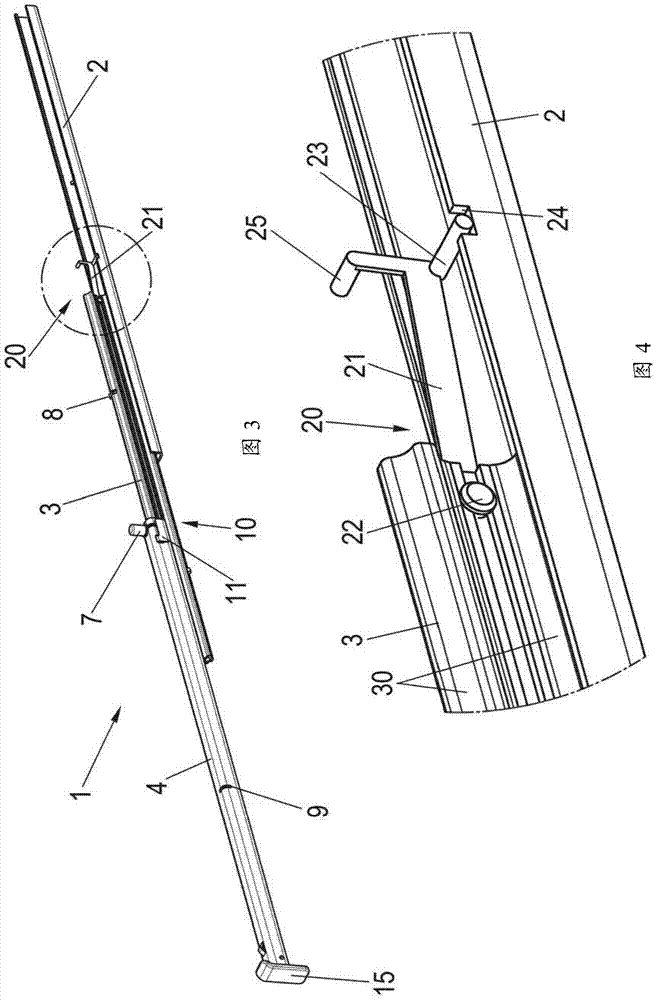

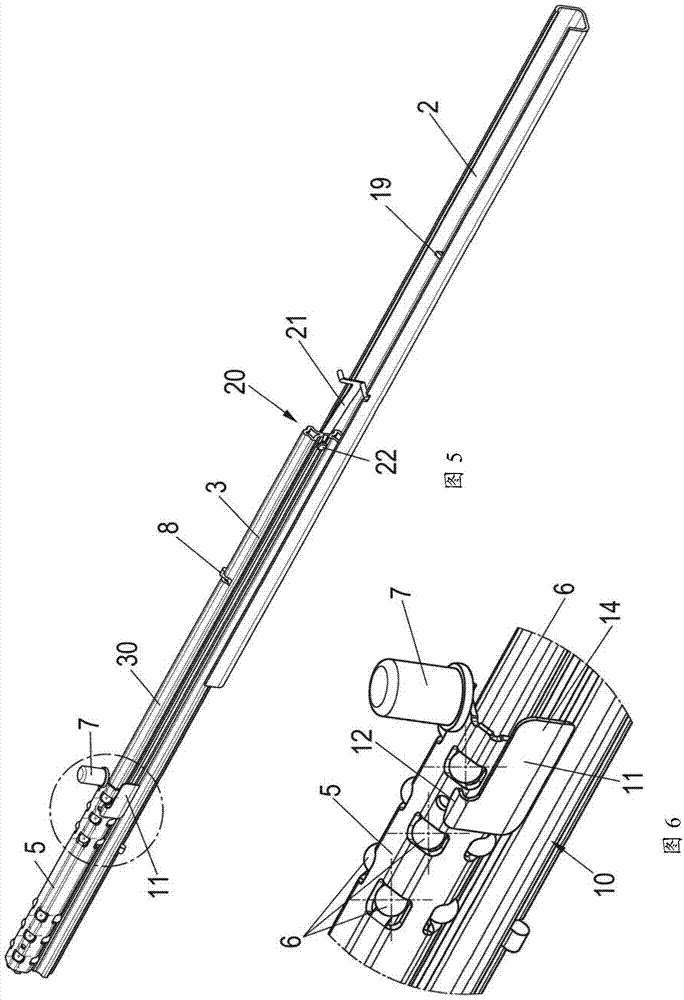

[0027] The pull-out guide 1 comprises a rail 2 which can be fastened to the main body of a piece of furniture or a household appliance and is usually arranged in a fixed manner, a rail 3 embodied as an intermediate rail, and a rail 4 (also called a sliding rail), on which Pushing elements (such as drawers, cooking material holders or other components) are mounted on them to make them movable.

[0028] Such as figure 2 As shown in , the snap-in mechanism 10 is located on the first track 4 , the snap-in mechanism 10 has a bendable elastic element 11 , and the elastic element 11 engages with the protrusion 12 through the opening 13 in the first track 4 . Furthermore, a locking mechanism 20 is provided which acts between the second rail 3 and the third rail 2 . Of course, it is also possible to arrange the engaging mechanism 10 on the second rail 3 or the third rail 2 and arrange the locking mechanism on the first rail 4 . Only the exemplary embodiments shown are explained belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com