One-step working platform limit adjustment device

A technology of working platform and adjusting device, which is applied in the direction of additive processing, etc., can solve the problems of no support force in the area or excessive support force, tilting, and uneven height of the printing platform, so as to reduce complexity and diversity, and have an exquisite structure The effect of reasonable and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

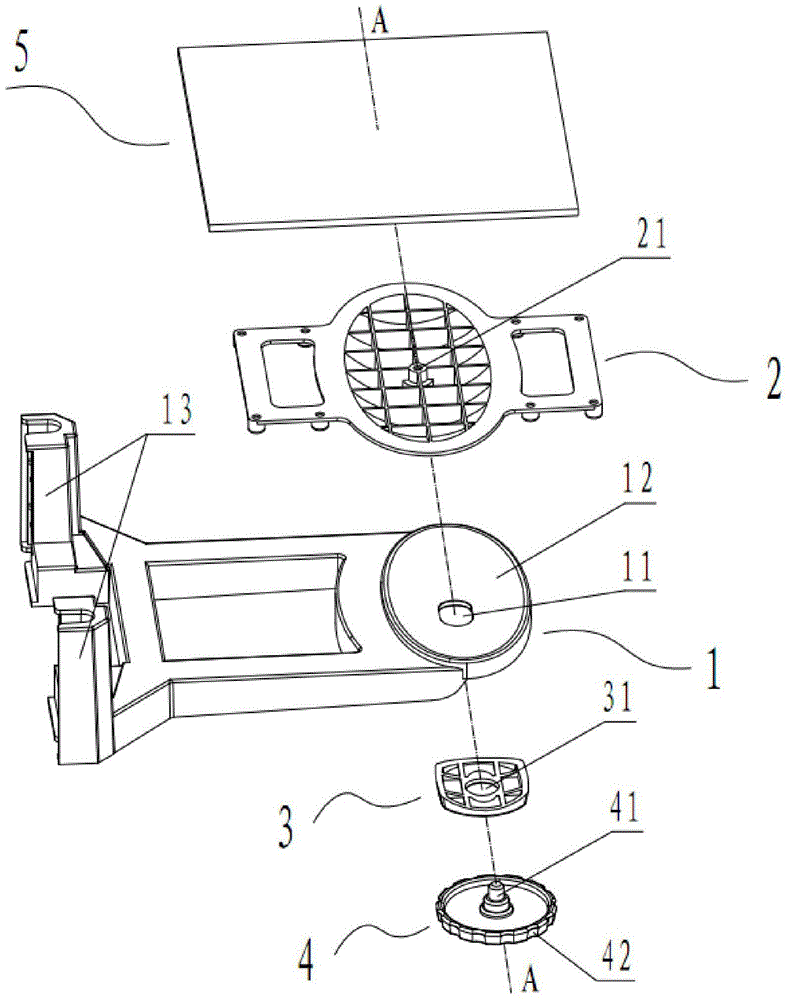

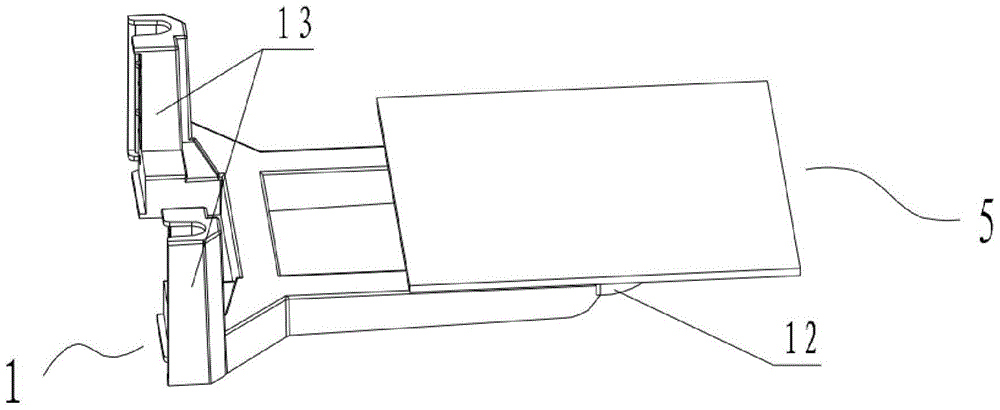

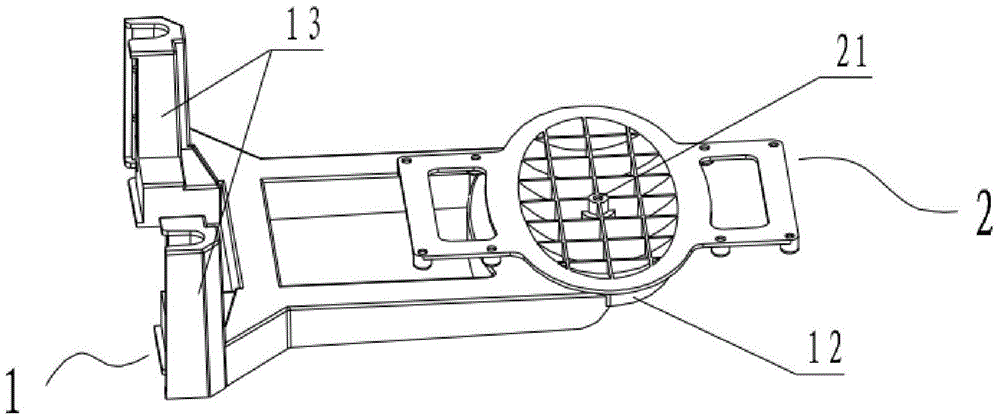

[0026] Example 1 : The one-step working platform limit adjustment device provided in this embodiment 1 has a schematic structure and an assembly drawing as shown in image 3 As shown, the schematic front view of the structure is shown in Figure 4 As shown, the schematic bottom view of the structure is as follows Figure 5 As shown, the schematic top view of the structure is as follows Figure 6 as shown, Figure 6 The C-C section view of Figure 7 As shown, the B-B sectional view is as follows Figure 8 As shown, the device base 1, working platform fixing frame 2, transition block 3 and hand wheel 4; the base 1 is provided with a mounting seat 12.

[0027] This device is used to install the structural schematic assembly drawing of working platform 5 as figure 1 As shown, the structural schematic general assembly diagram is shown in figure 2 As shown, the working platform 5 is fixedly arranged on the top surface of the working platform fixing frame 2 by means of bol...

Embodiment 2

[0033] Example 2: The structure is basically the same as that of Embodiment 1, and the similarities are no longer repeated, but the difference is:

[0034]It also includes a fastening nut (not shown in the figure); the hand wheel 4 passes through the first through hole 31, the second through hole 11, and the third through hole 21 through its rod portion 41 in turn and connects with the fastening nut (not shown in the figure). Shown) threaded connection, fixedly connected with the working platform fixing frame 2.

[0035] Taking Example 1 for adjusting the 3D printing platform in a 3D printer as an example, the working platform 5, such as a working board, is firmly installed on the working platform fixing frame 2 to form a 3D printing platform, and the top or bottom cross-section of the mounting seat 12 on the base 1 On the premise that the two lines of symmetry are aligned with the X-axis and Y-axis directions required for 3D printing and installed in the 3D printer, the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com