Powder supplying device for colorful 3DP (three-dimensional printing) machine

A technology of 3D printers and powder supply devices, applied in the direction of additive processing, etc., can solve the problems of overall cost reduction, blockage of ink supply pipelines, volume reduction, etc., and achieve the effect of reducing the overall size, preventing blockage, and increasing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

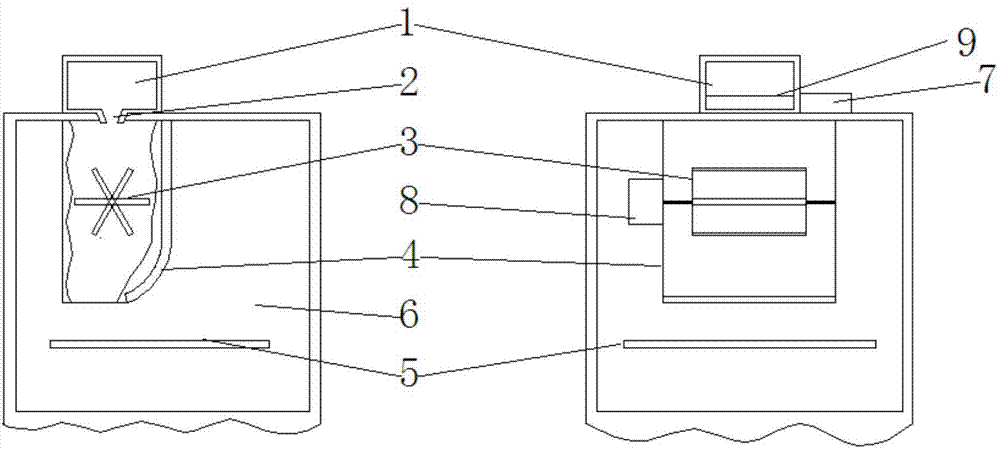

[0015] A powder supply device for a 3DP color three-dimensional printer, the device comprising: a computer, a powder supply box arranged outside the top of the printer, a powder supply port provided at the lower part of the powder supply box, a powder rotor provided in a molding chamber and directly below the powder supply port There is an arc-shaped sliding powder plate and a powder supply platform on one side of the fan and the powder rotating fan. The powder supply port of the powder supply box is connected with the arc-shaped powder sliding plate. A powder supply valve controlled by a motor is installed in the powder supply box.

[0016] The upper powder supply is adopted, and the powder supply port is provided with a powder rotating fan and an arc-shaped sliding powder plate connected with the powder supply box. This powder fan design can well isolate the powder supply box from the molding chamber to reduce dust, and the design of the arc-shaped sliding powder plate makes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com