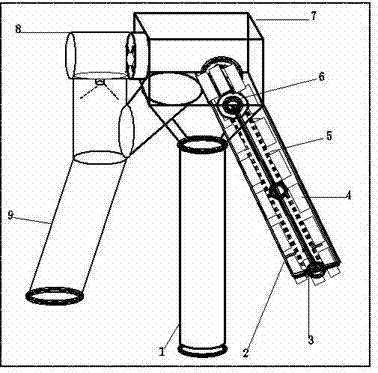

Dual-scrape energy-saving environment-friendly handling set

An energy-saving and environmental protection, loading and unloading equipment technology, applied in the direction of loading/unloading, transportation and packaging, to achieve the effect of overcoming the technical problems of loading and unloading and filling the technical problems of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0026] Fix the bottom end fixing plate of the hydraulic lift pipe in the support column 1 of the double scraping energy saving and environmental protection loading and unloading equipment of the present invention (or move it through the preset universal wheel) at the desired position, and respectively install the drive 6, the vacuum cleaner 8 and its accessories. The sprayer, the rotary disk and the inner hydraulic lift pipe attached to the support column 1 are respectively connected with the external electric control and hydraulic control buttons, so that the corresponding settings are in working state. Then, turn on the buttons of the driver 6 and the vacuum cleaner 8 respectively, and the upper shaft of the driver 6, that is, the driving shaft 3, together drives the scraper belt 5 and the scraper plate 4 connected to it between the upper and lower layers of the separator in the scraper pipe 2. During the operation, the scraper plate 4 scrapes and discharges the granular good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com