High-pile wharf bulk cargo self-unloading platform

A high-piled wharf and self-unloading technology, applied in the field of loading or unloading of ship cargo, can solve the problems of high energy consumption, consumption of approach bridges, easy corrosion and wear of hinges, etc., so as to avoid ship heeling and save energy consumption. , Improve the effect of unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

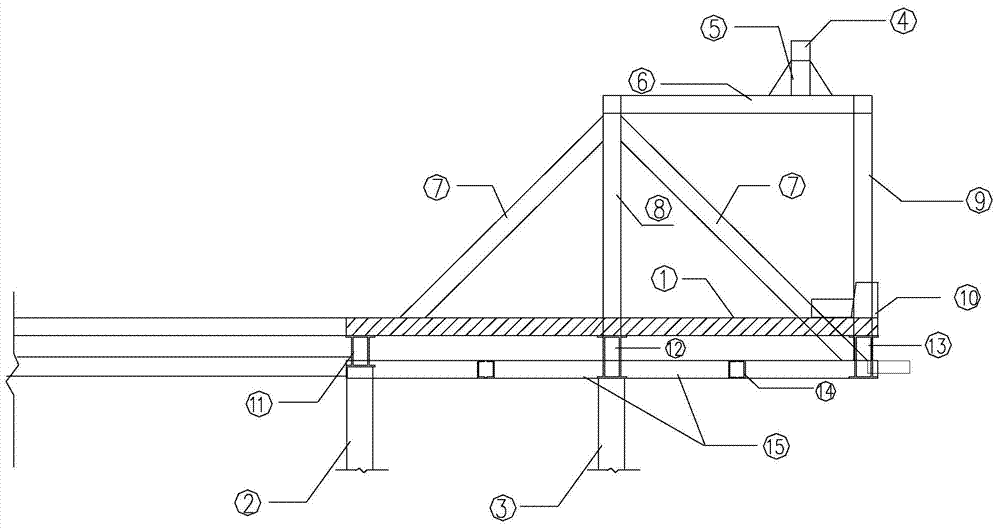

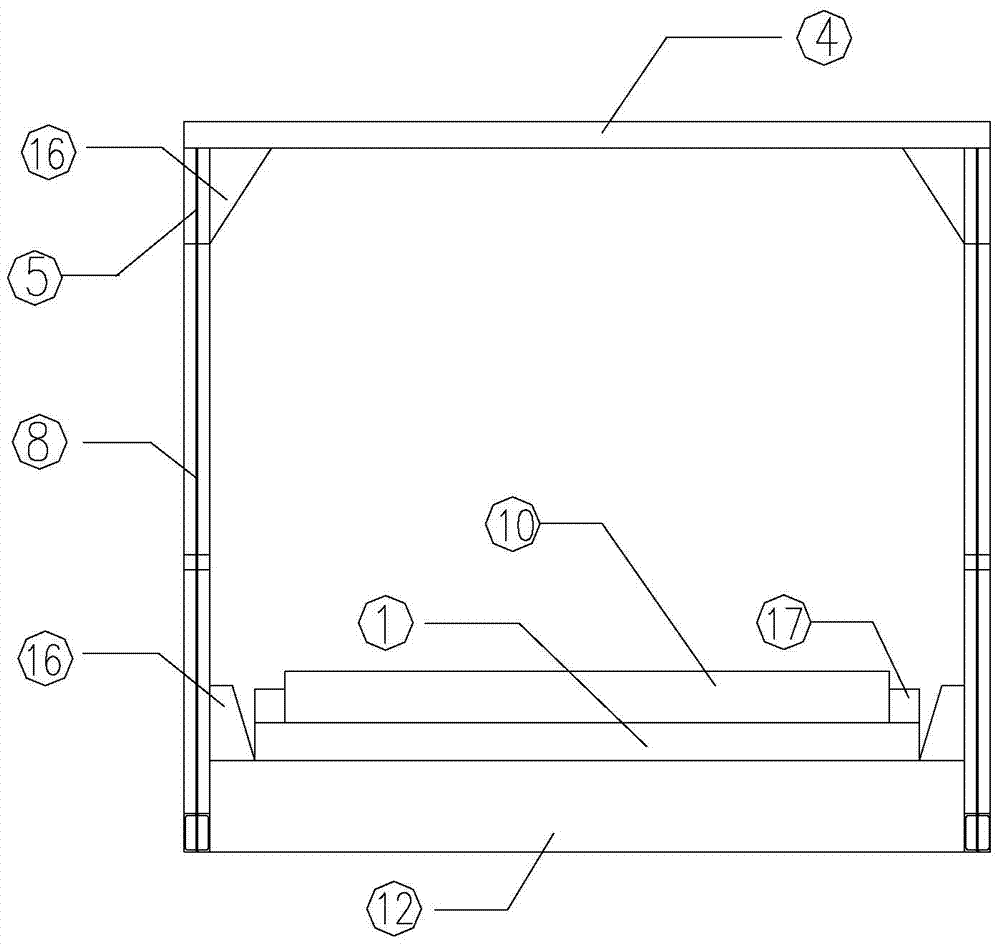

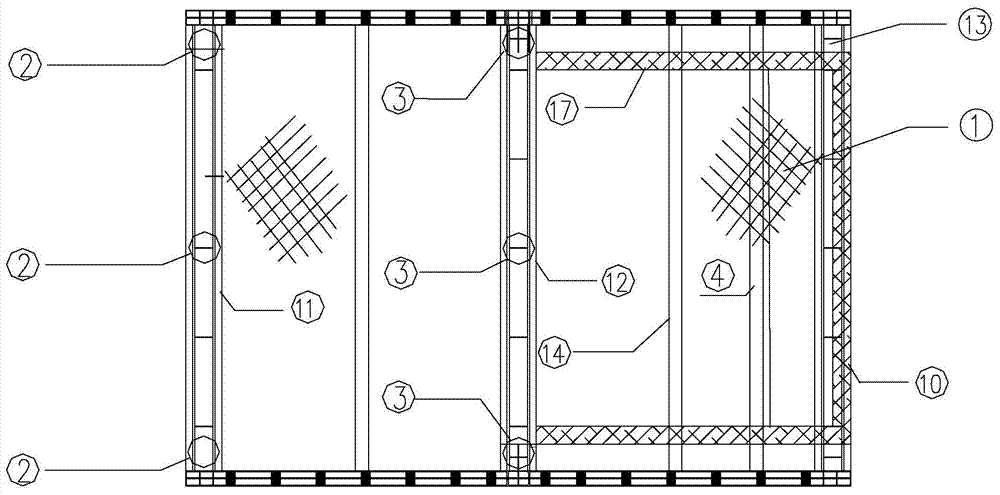

[0026] The high pile wharf bulk cargo self-unloading platform of the present embodiment is as figure 1 , figure 2 and image 3 As shown, it is composed of reinforced concrete panel 1, anchor pile 2, support pile 3 and steel triangular truss. The total length of the platform is 7m, and the length of the cantilever end is 3.5m. The end of the reinforced concrete panel 1 has a wheel guard 10, and both sides of the water side channel slab are provided with edge stones 17. The triangular truss is mainly composed of chassis, vertical bar 8, inclined bar 7, top horizontal bar 6, and top beam 4. The length of the truss is 7m, the width is 5m, and the total height is 5m. The chassis is a Japanese-shaped main frame made up of a first beam 11 , a second beam 12 , a third beam 13 and a pair of horizontal bars 15 , and a bottom tie beam 14 is also connected between the pair of horizontal bars 15 . Also be welded with lateral reinforcing plate 16 in the right angle that chassis and vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com