Coiled material hoisting mechanism

A coiled material and sleeve technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of high labor intensity, low efficiency, inconvenient overturning or lifting mechanism connection, etc., so as to reduce labor intensity and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

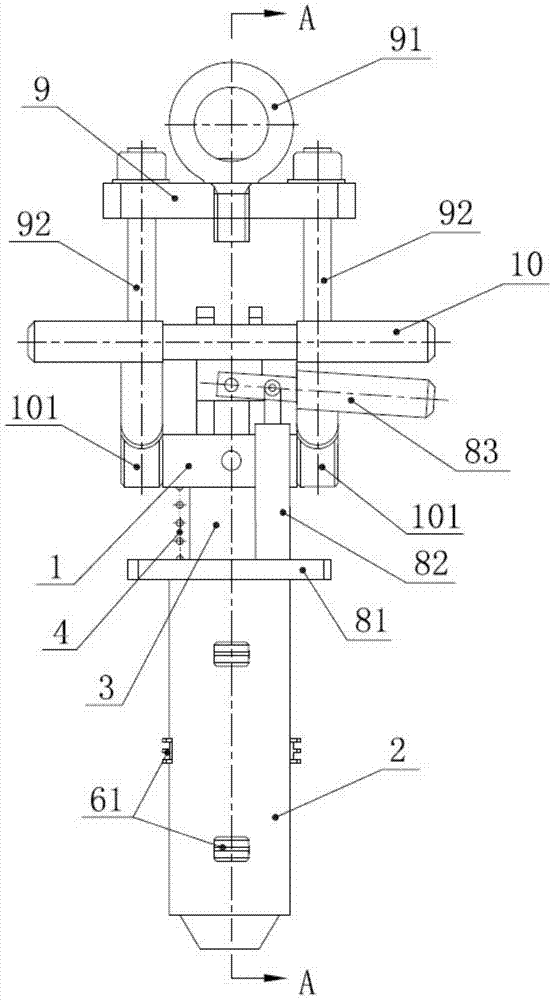

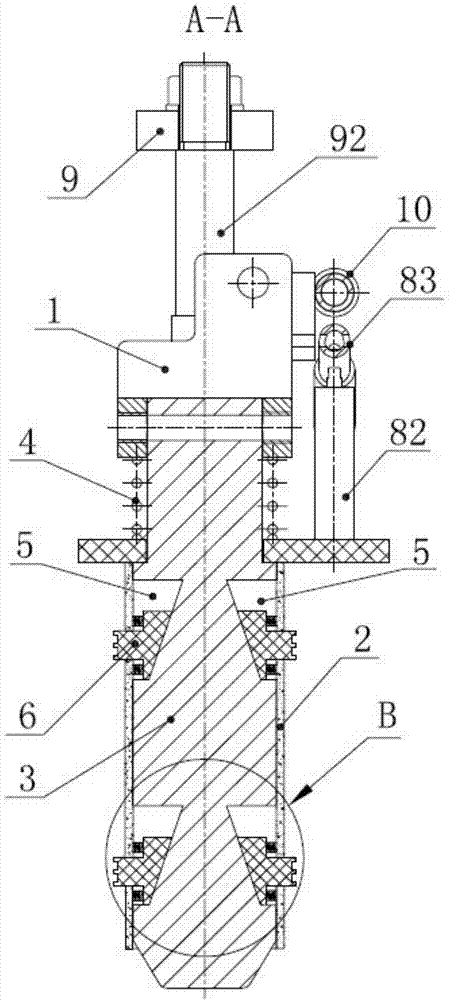

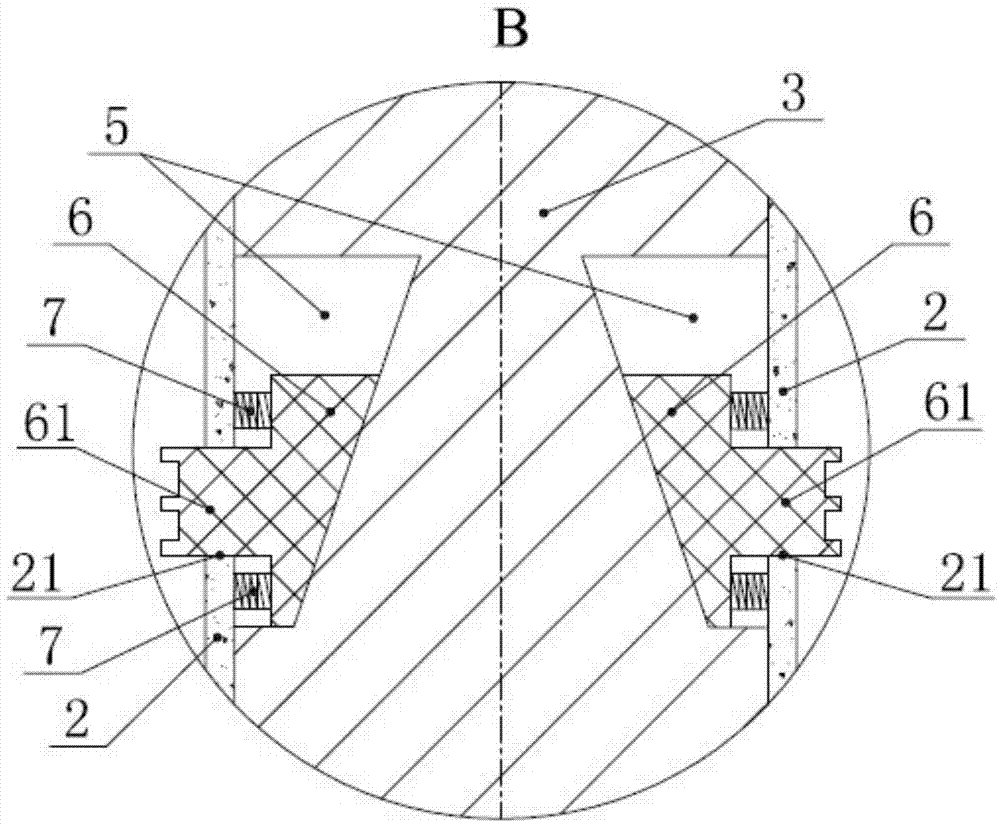

[0018] Such as Figure 1 to Figure 3 As shown in , the coil lifting mechanism of the present invention includes a mounting frame 1, a sleeve 2 and a valve core 3 located in the sleeve and capable of moving axially along the sleeve, the upper end of which passes through The sleeve is connected to the installation frame behind, and a sleeve return spring 4 is arranged between the upper end of the sleeve and the installation frame 1; at least one set of slope chute groups is provided on the outer peripheral surface of the valve core located in the sleeve 2, The slope chute group includes two mirror-image-symmetrically distributed slope chute 5, and a slope surface inclined relative to the axis of the valve core is arranged in the slope chute 5, and between each slope chute 5 and the sleeve 2 A slider 6 is provided on which a mating surface that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com