Assembly type concrete filled steel tube shear wall splitting and assembling connection structure and assembling connection method

A steel pipe concrete and connection structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of less structural research, long lap length, inconvenient construction, etc., to achieve improved overall performance, small width, and split The effect of a reasonable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

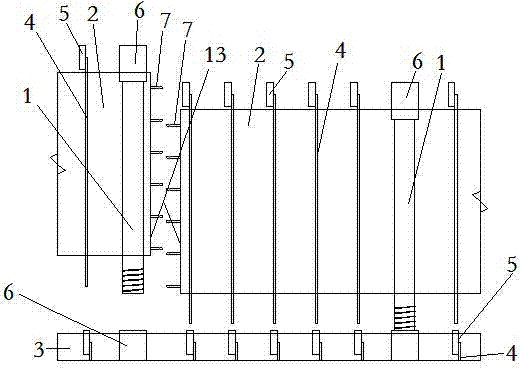

[0045] Embodiment 1, referring to Fig. 1, Figure 4 : It is a prefabricated steel pipe concrete shear wall split and assembled connection structure in the form of a straight wall section, mainly including: prefabricated steel pipe concrete frame column 1, prefabricated shear wall 2, cast-in-place floor 3, vertical reinforcement of shear wall 4 , steel bar sleeve 5, steel pipe sleeve 6, shear wall horizontally protruding U-shaped closed steel bar 7, cast-in-place vertical insert bar 8, rectangular stirrup bar 9, cast-in-place concrete 10, grouting material 11, etc. The specific structure is as follows:

[0046] The vertical steel bar 4 of the shear wall is vertically pierced in the prefabricated shear wall 2, and the upper end of the vertical steel bar 4 of the shear wall is welded to the outer wall of the steel bar sleeve 5 and protrudes from the upper end of the prefabricated shear wall 2 to connect with the upper shear wall. The vertical steel bars of the wall are connected w...

Embodiment 2

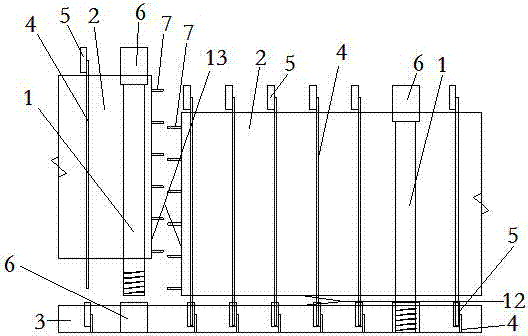

[0050] Embodiment 2, referring to Fig. 2, Figure 5 : It is a prefabricated steel pipe concrete shear wall disassembly and assembly structure in the form of L-shaped wall section, mainly including: prefabricated steel pipe concrete frame column 1, prefabricated shear wall 2, prefabricated L-shaped flange wall 15, cast-in-place floor 3 , Shear wall vertical steel bars 4, steel bar sleeves 5, steel pipe sleeves 6, shear wall horizontally protruding U-shaped closed steel bars 7, cast-in-place vertical bars 8, rectangular stirrups 9, cast-in-place concrete 10, grouting Material 11 etc., the specific structure is as follows:

[0051] The vertical steel bar 4 of the shear wall is vertically pierced in the prefabricated shear wall 2, and the upper end of the vertical steel bar 4 of the shear wall is welded to the outer wall of the steel bar sleeve 5 and protrudes from the upper end of the prefabricated shear wall 2 to connect with the upper shear wall. The vertical steel bars of the...

Embodiment 3

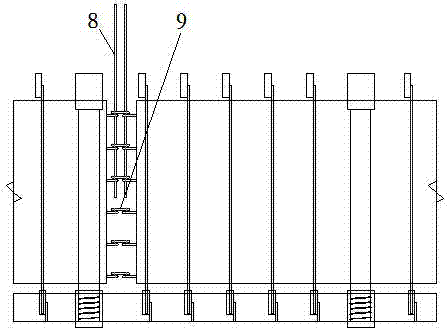

[0055] Embodiment 3, referring to Fig. 3, Figure 6 : It is a prefabricated steel pipe concrete shear wall disassembly and assembly structure in the form of an I-shaped wall section, mainly including: prefabricated steel pipe concrete frame column 1, prefabricated shear wall 2, prefabricated I-shaped flange wall 16, cast-in-place floor 3 , Shear wall vertical steel bars 4, steel bar sleeves 5, steel pipe sleeves 6, shear wall horizontally protruding U-shaped closed steel bars 7, cast-in-place vertical bars 8, rectangular stirrups 9, cast-in-place concrete 10, grouting Material 11 etc., the specific structure is as follows:

[0056] The vertical steel bar 4 of the shear wall is vertically pierced in the prefabricated shear wall 2, and the upper end of the vertical steel bar 4 of the shear wall is welded to the outer wall of the steel bar sleeve 5 and protrudes from the upper end of the prefabricated shear wall 2 to connect with the upper shear wall. The vertical steel bars of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com