Hydraulic interlocking control loop

A hydraulic circuit and control circuit technology, applied in fluid pressure actuation devices, fluid pressure actuation system safety, servo motors, etc., can solve problems such as increasing the number of hidden dangers of oil leakage points, reducing circuit reliability, and increasing manufacturing costs. Achieve the effects of reducing the number of hidden dangers at oil spill points, increasing reliability, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

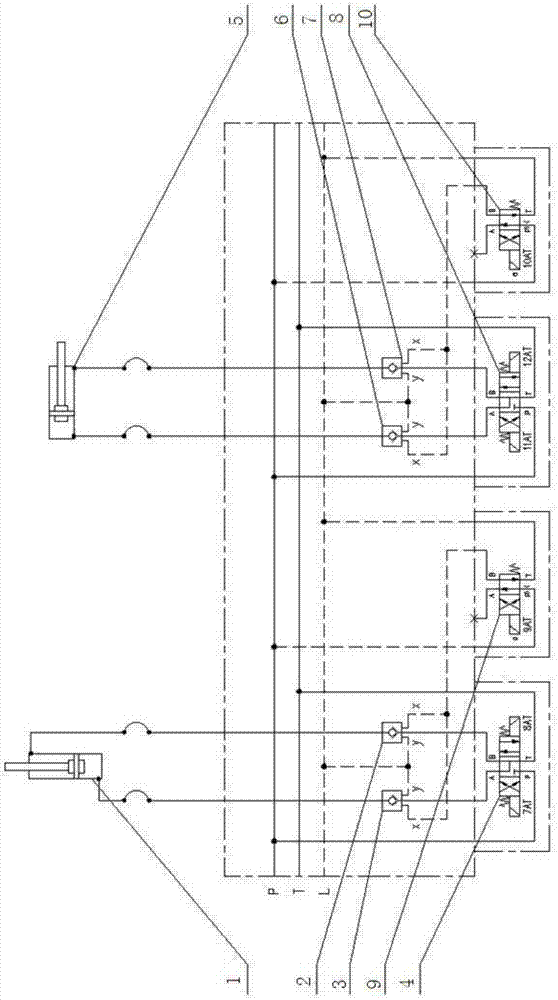

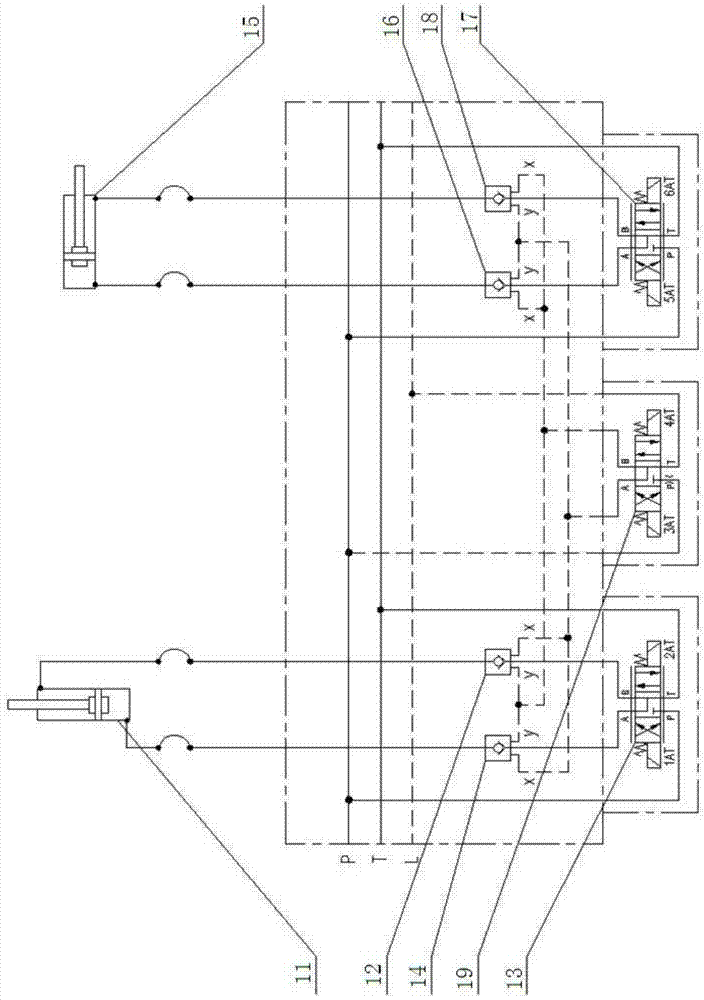

[0015] Such as figure 2 As shown, the hydraulic interlock control circuit in this embodiment includes a first hydraulic circuit and a second hydraulic circuit. The first hydraulic circuit is mainly connected by an oil cylinder I11, a hydraulic lock Ia12, a reversing valve I13 and a hydraulic lock Ib14. The second hydraulic circuit is mainly composed of oil cylinder II15, hydraulic lock IIa16, reversing valve II17 and hydraulic lock IIb18, and also includes reversing valve III19 for simultaneously controlling the hydraulic locks in the first and second hydraulic circuits , the left oil outlet A of the reversing valve III19 is connected in parallel with the control oil ports x of the hydraulic locks Ia12 and Ib14 in the first hydraulic circuit and the leakage oil ports y of the hydraulic locks IIa16 and IIb18 in the second hydraulic circuit....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com