Boiler pipe dirt cleaner

A technology for cleaning devices and pipelines, which is applied in the direction of cleaning heat transfer devices, flushing, lighting and heating equipment, etc., to achieve the effect of improving the flushing effect and widening the market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

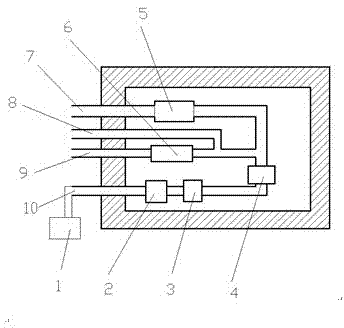

[0020] The invention provides a boiler pipe dirt cleaning device, which is characterized in that: the boiler pipe dirt cleaning device includes an air pump 1, a gas pressure converter 4, a vortex generator 6, a water injection pipe 7, an agent injection pipe 8, and a water outlet pipe 9 , gas injection pipe 10, mixture pipe 11, shell 12;

[0021] The air pump 1 is connected to the gas injection pipe 10, the water injection pipe 7 is connected to the mixture pipe 11 after joining the gas injection pipe 10, the injection pipe 8 is connected to the mixture pipe 11, the outlet end of the mixture pipe 11 is connected to one end of the vortex generator 6, and the vortex is generated The other end of the device 6 is connected to the water outlet pipe 9, and the water injection pipe 7, the agent injection pipe 8, the water outlet pipe 9 and the gas injection pipe 10 all pass through the shell 12 and are fixed on the side wall of the shell 12.

[0022] The boiler pipeline dirt cleaning...

Embodiment 2

[0027] The invention provides a boiler pipe dirt cleaning device, which is characterized in that: the boiler pipe dirt cleaning device includes an air pump 1, a gas pressure converter 4, a vortex generator 6, a water injection pipe 7, an agent injection pipe 8, and a water outlet pipe 9 , gas injection pipe 10, mixture pipe 11, shell 12;

[0028] The air pump 1 is connected to the gas injection pipe 10, the water injection pipe 7 is connected to the mixture pipe 11 after joining the gas injection pipe 10, the injection pipe 8 is connected to the mixture pipe 11, the outlet end of the mixture pipe 11 is connected to one end of the vortex generator 6, and the vortex is generated The other end of the device 6 is connected to the water outlet pipe 9, and the water injection pipe 7, the agent injection pipe 8, the water outlet pipe 9 and the gas injection pipe 10 all pass through the shell 12 and are fixed on the side wall of the shell 12.

[0029] The boiler pipe dirt cleaning dev...

Embodiment 3

[0033] The invention provides a boiler pipe dirt cleaning device, which is characterized in that: the boiler pipe dirt cleaning device includes an air pump 1, a gas pressure converter 4, a vortex generator 6, a water injection pipe 7, an agent injection pipe 8, and a water outlet pipe 9 , gas injection pipe 10, mixture pipe 11, shell 12;

[0034] The air pump 1 is connected to the gas injection pipe 10, the water injection pipe 7 is connected to the mixture pipe 11 after joining the gas injection pipe 10, the injection pipe 8 is connected to the mixture pipe 11, the outlet end of the mixture pipe 11 is connected to one end of the vortex generator 6, and the vortex is generated The other end of the device 6 is connected to the water outlet pipe 9, and the water injection pipe 7, the agent injection pipe 8, the water outlet pipe 9 and the gas injection pipe 10 all pass through the shell 12 and are fixed on the side wall of the shell 12.

[0035] The boiler pipeline dirt cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com