Vegetable harvesting cutter cutting factor selection testing platform

A technology for selecting tests and test benches, which is applied in the field of selecting test platforms for cutting factors of vegetable harvesting tools, and can solve the problems that cannot explain the influence of comprehensive factors on harvesting efficiency and success rate, cutting factors cannot be accurately controlled, and vegetable leaves are damaged and harvested. , to achieve the effect of strong practicability, high adaptability, and improved success rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

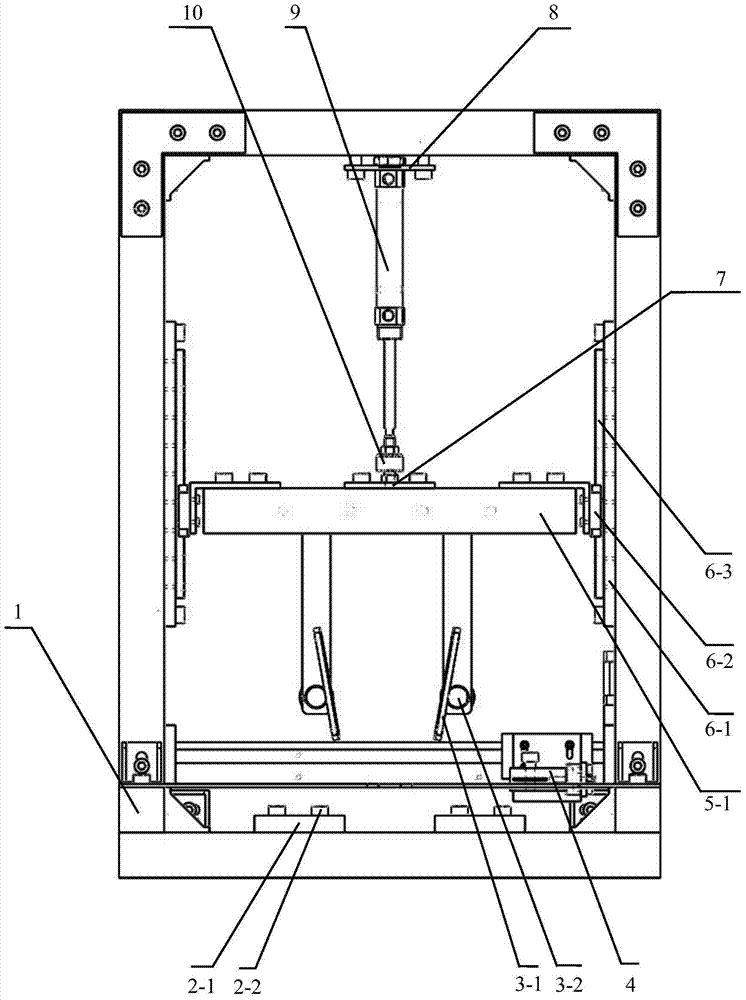

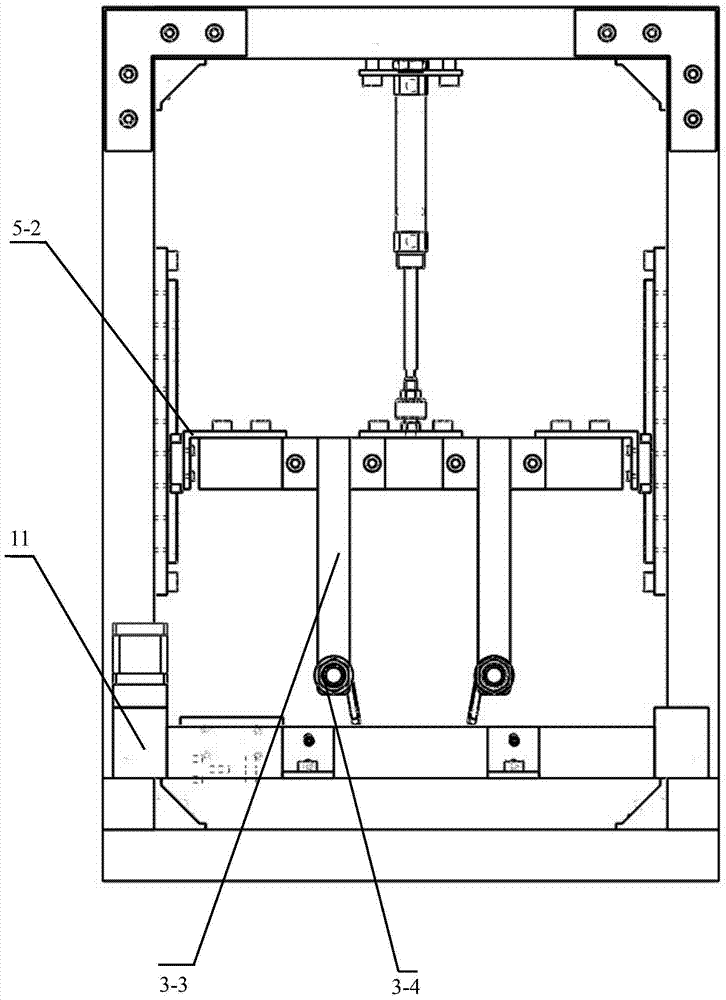

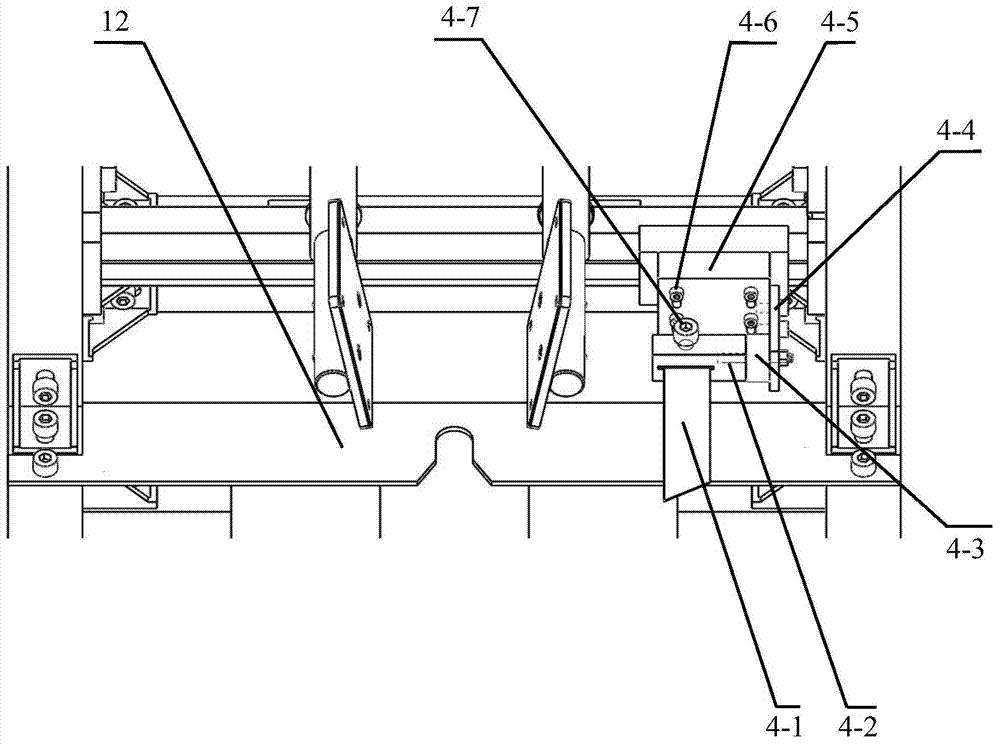

[0017] The present invention will be further explained below in conjunction with the drawings:

[0018] Such as Figure 1-Figure 4 As shown, a vegetable harvesting and cutting factor test platform includes a vegetable fixing part, a tool harvesting and cutting part, and a vegetable clamping and extracting part. The vegetable fixing part includes the test operation table 2-1, the tightening bolt 2-2, the vegetable fixing plate 12; the cutting tool part includes the load cell tooling 4, the cutter 4-1, the sensor connection block I4-2, the load cell 4 -3. Sensor connection block II4-4, angle adjustment block 4-5, adjustment bolt 4-6, tightening bolt 4-7, synchronous belt stepping linear slide 11; vegetable clamping and extraction part includes clamping plate 3- 1. Clamping plate fixed shaft 3-2, adjustable clamping claw 3-3, lock nut 3-4, clamping claw adjusting beam 5-1, sliding block connecting plate 5-2, sliding rail pad 6 1. Slide block 6-2, slide rail 6-3, floating joint con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com