Processing box and image forming device matched with processing box

A technology for processing boxes and images, which is applied in the fields of electrical recording technology using charge graphics, equipment for using electrical recording technology using charge graphics, and electrical recording technology, and can solve problems such as inability to identify features of image forming devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

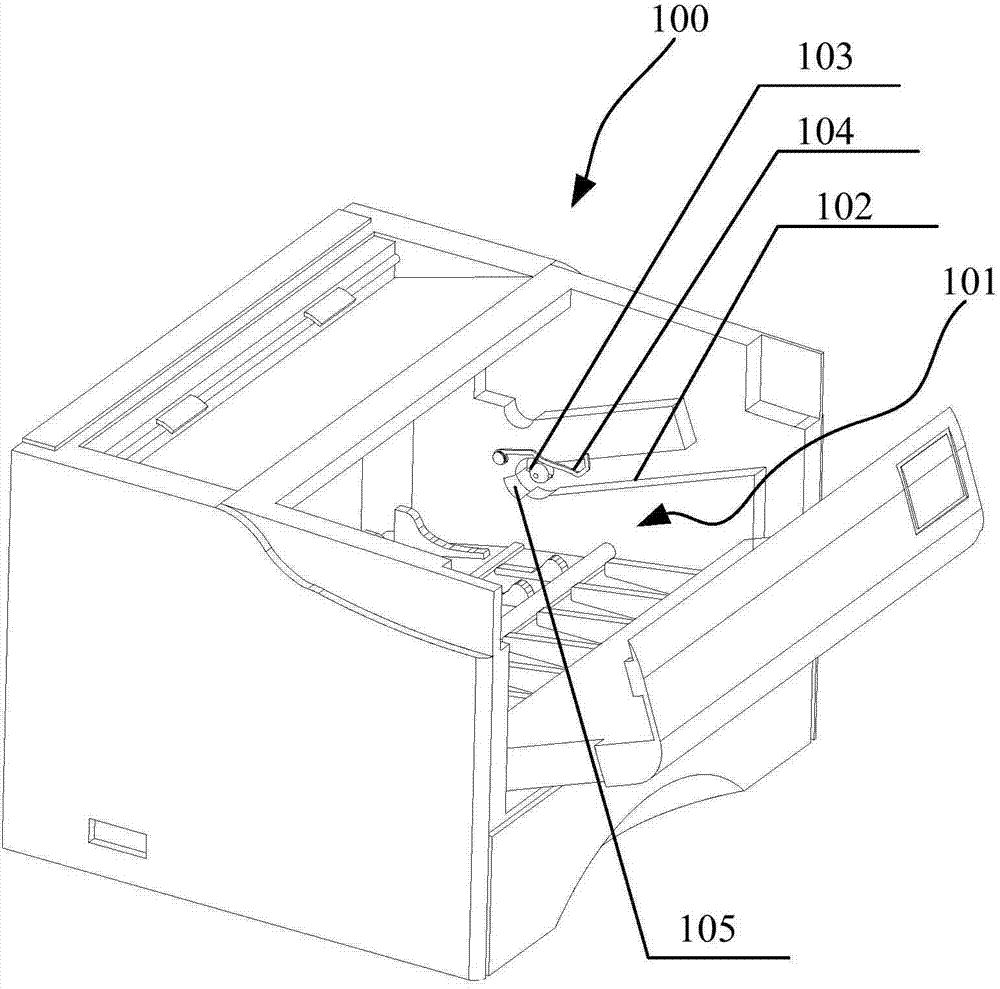

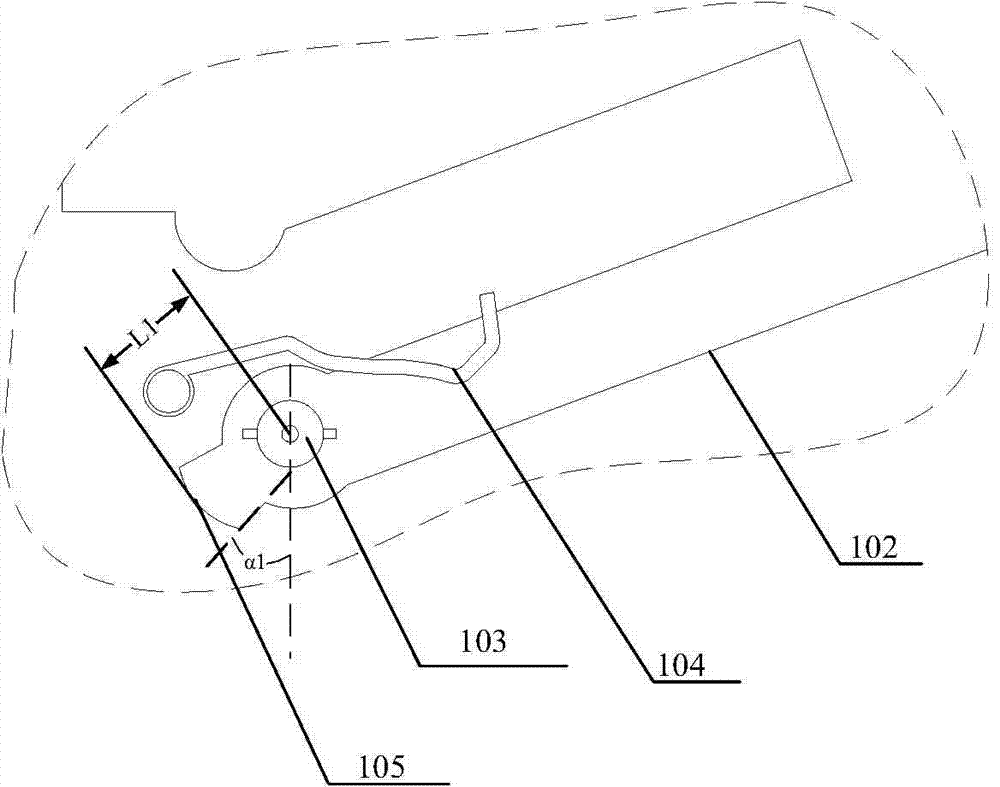

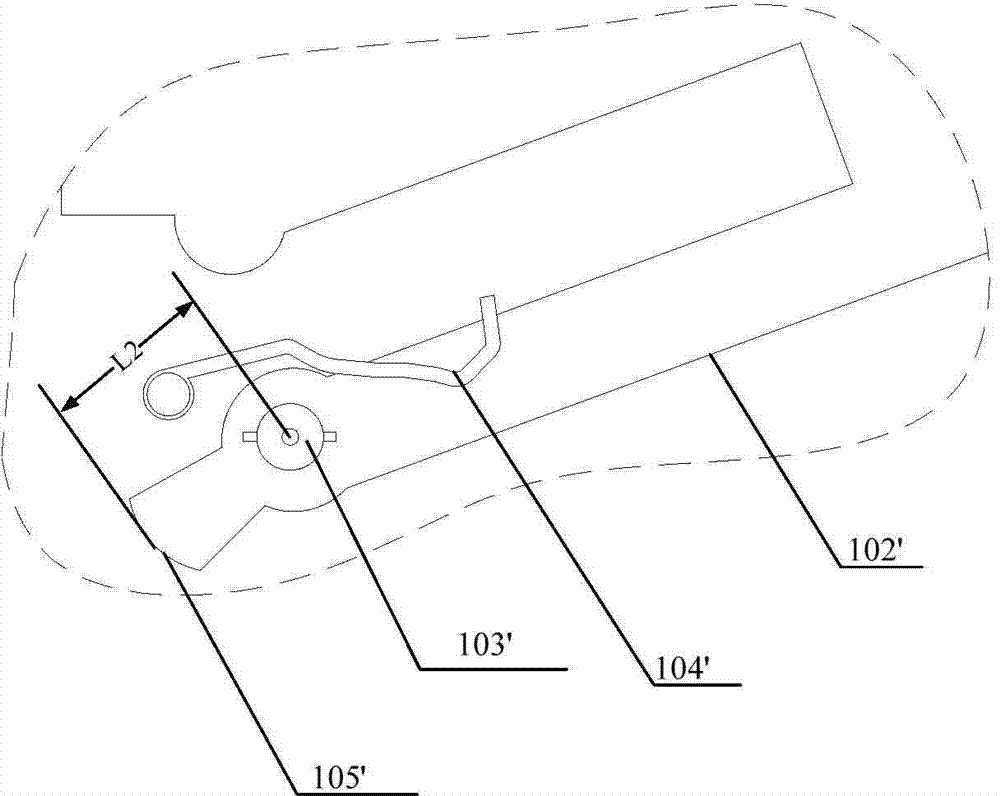

[0039] Such as figure 1 , Figure 2a-2c , image 3 As shown, preferably, the present embodiment 1 provides an image forming apparatus 100 comprising a process cartridge installation unit 101 configured to allow the process cartridge 1 (described in detail below) to be detachably installed therein; the drive mechanism is provided There is a motor, and the drive end 103, 103', 103 "connected with the motor, the drive end 103, 103', 103 "can drive the drive head 130 installed on the process box 1 in the image forming device 100 to rotate; guide rails 102, 102 ', 102" are arranged so that the process box 1 can be installed to a predetermined position along the predetermined track on the guide rail 102, 102', 102"; In the space defined by the guide rails 102, 102', 102", the dimensional relationship between the front ends 105, 105', 105" of the guide rails 102, 102', 102" and the driving ends 103, 103', 103" determines the size of the image forming apparatus 100. type. (The refe...

Embodiment 2

[0051] Such as Figures 6a-6c As shown, preferably, the difference between the image forming apparatus provided by the second embodiment and the first embodiment is that sensors 206, 206', 206", the sensor can be a travel switch, a position sensor, or a light sensor. Other features are the same as in the first embodiment.

[0052] Such as Figure 7 , Figure 8a As shown, preferably, the difference between the process cartridge 2 provided in Embodiment 2 and the process cartridge 1 provided in Embodiment 1 is that, in order to simplify the structure, the drive head 23 is directly connected to one end of the photosensitive element 24, and the drive head 23 The axis Y2 is inclined to the axis Y1 of the photosensitive element 24 in the natural state, while in the coupled state, Y2 is coaxial with Y1. And both sides of the process box 2 are also provided with positioning posts, these positioning posts are arranged on both sides of the process box, during the installation process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com