Device facilitating touch screen assembly

A touch screen and component technology, applied in the input/output process of data processing, instruments, electrical digital data processing and other directions, can solve the problems of scrapping the touch screen assembly 20 and the fixed frame 10, uneven gaps, waste of cost, etc., and achieves a simple structure. , Guarantee the appearance, avoid the effect of placement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

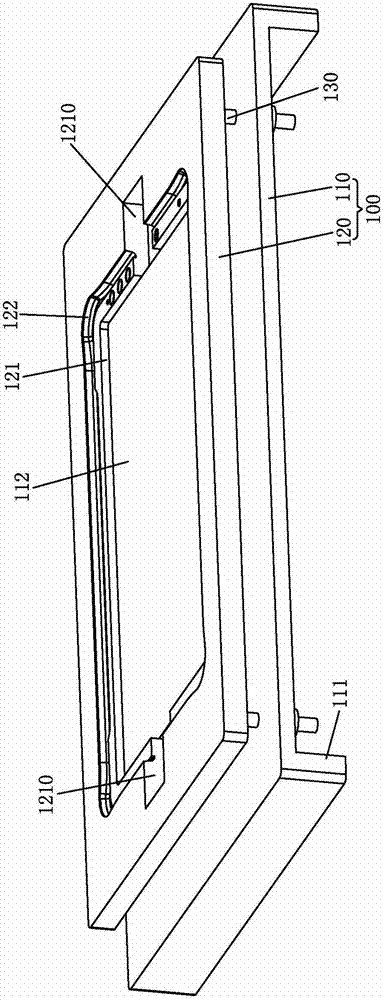

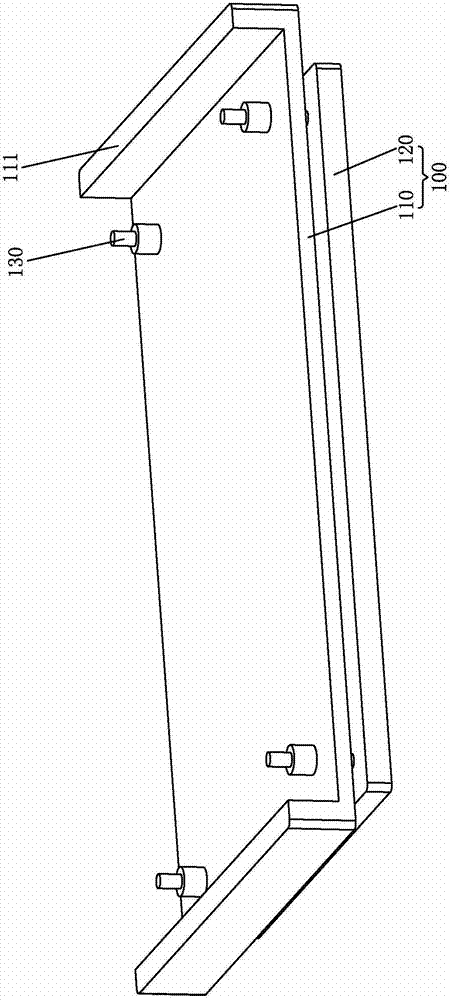

[0023] For this purpose, please refer to the figure 2 and image 3 It is shown that the device 100 for facilitating touch screen assembly provided by the present invention is applied to the assembly of touch screen equipment. The touch screen equipment includes a fixed frame 10 and a touch screen assembly 20 installed on the fixed frame 10. The device 100 includes:

[0024] The first support plate 110 has two support plates 111 arranged downward along its body at both ends, and a boss 112 is provided on the upper surface of the first support plate 110, and the boss 112 is used to place the touch screen assembly 20 ;

[0025] The second support plate 120 is arranged on the top of the first support plate 110, and the body of the second support plate 120 is provided with a through groove 121. Groove 122, the through groove 121 is sleeved on the upper end of the boss 112, the groove 122 is used to place the fixed frame 10;

[0026] One end of a plurality of elastic struts 130 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com