A self-adaptive adjustable vise

An self-adaptive and adjustable technology, applied in vices, manufacturing tools, etc., can solve problems such as the inability to adjust the coaxiality of the screw and the guide nut, the wear of the screw and the guide nut, and shorten the service life of the vise. High self-adaptive adjustment ability, slow down vibration and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

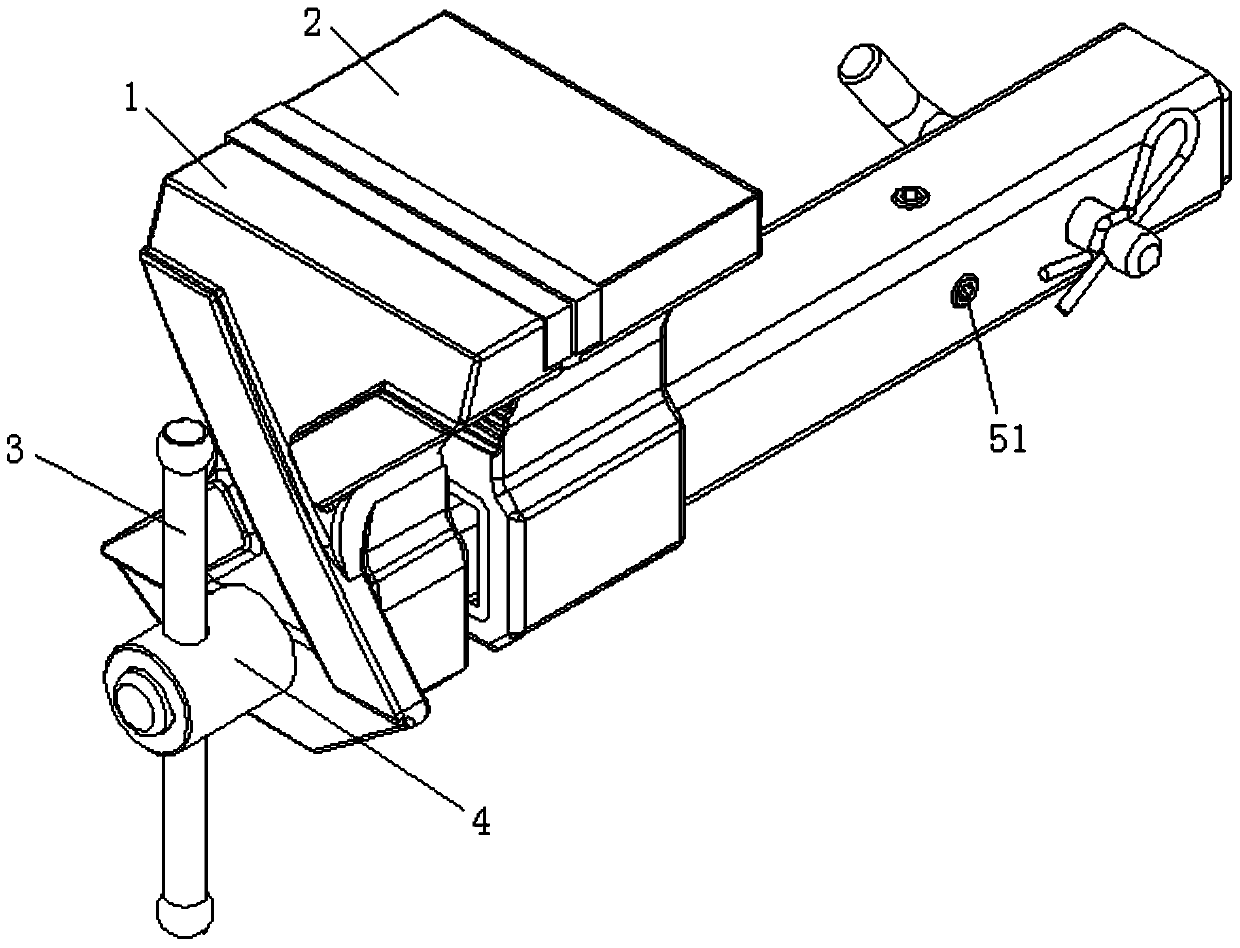

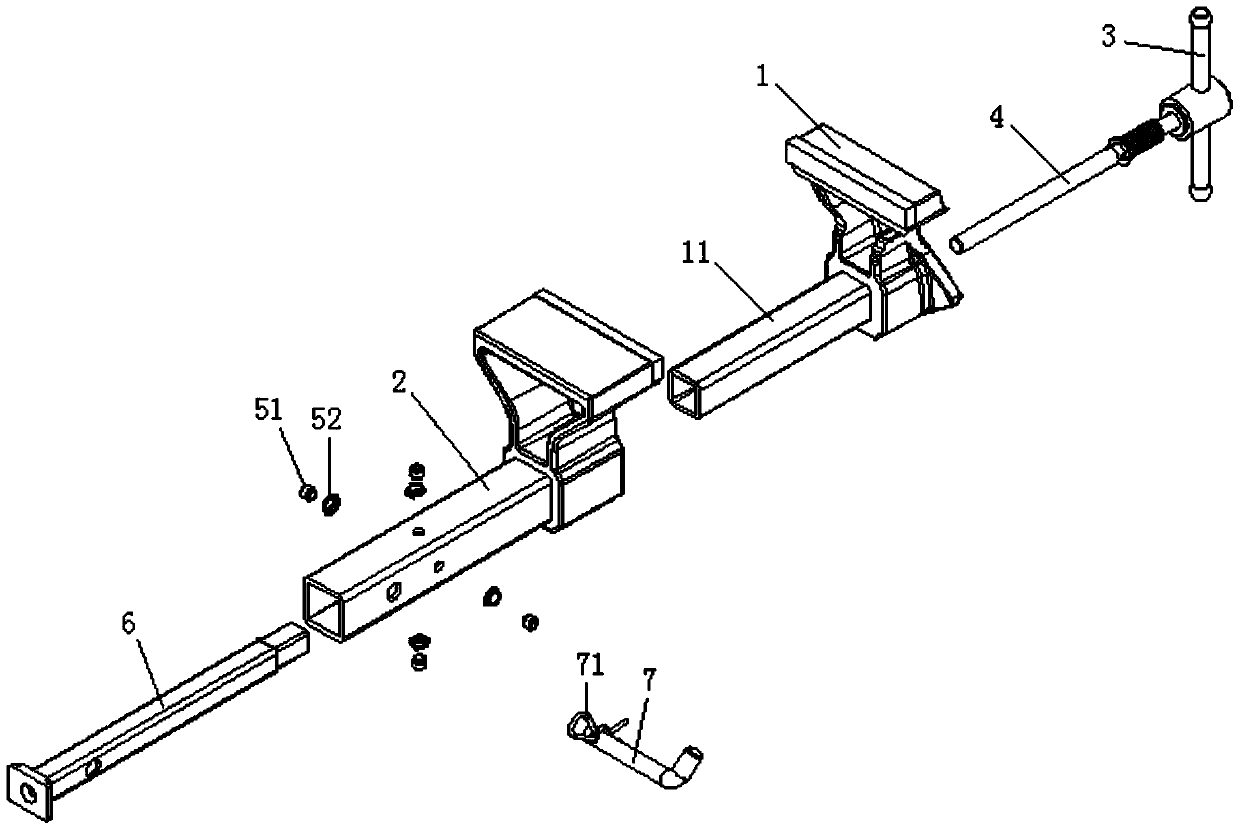

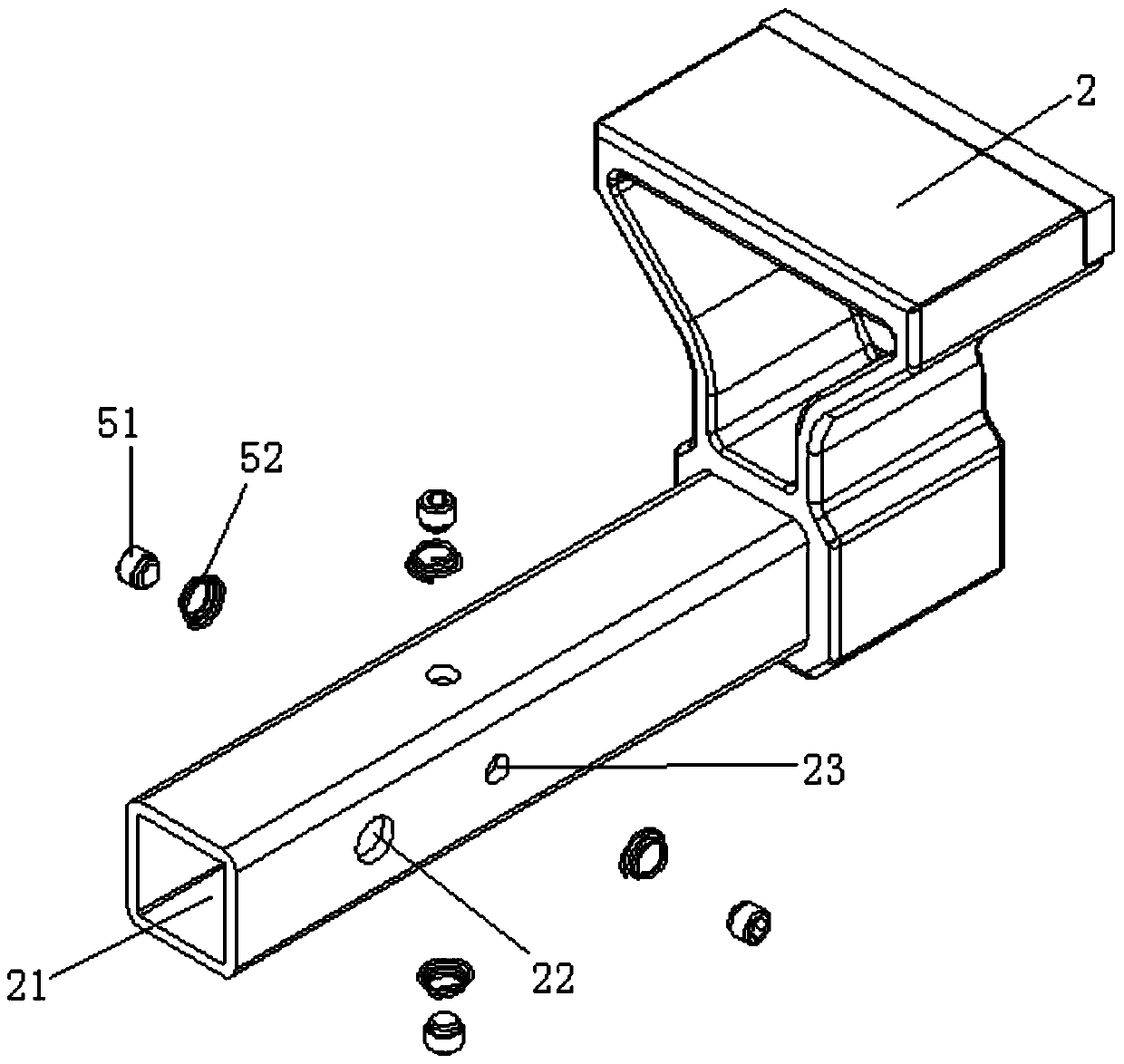

[0032] see Figure 1-3 , a self-adaptive adjustable vise, comprising a fixed pliers body 2, a movable pliers body 1, a guide sleeve 6, a lead screw 4, a handle 3 and an adaptive adjustment device, wherein,

[0033] The guide sleeve 6 is passed through the cavity 21 of the fixed pliers body 2 and connected with the fixed pliers body 2;

[0034] The lead screw 4 is respectively connected with the movable pliers body 1 and the handle 3, and the lead screw 4 is penetrated in the guide sleeve 6 and screwed with the guide sleeve 6;

[0035] The adaptive adjustment device is used to adjust the coaxiality between the screw 4 and the guide sleeve 6, and the adaptive adjustment device flexibly adjusts the coaxiality between the screw 4 and the guide sleeve 6. Concentricity. In the present invention, the coaxiality between the lead screw and the guide sleeve can be automatically adjusted through the self-adaptive adjustment device, which reduces the deviation in the operation process c...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that the self-adaptive adjustment device includes an elastic component and an adjustment screw, the adjustment screw is embedded in the through hole of the side wall of the cavity, and one end of the elastic component The front end of the adjustment screw is abutted or screwed, and the other end is abutted with the outer surface of the guide sleeve. The elastic part is a spring or a shrapnel. Other structures and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0047] In this embodiment, an elastic member and an adjusting screw are provided to adjust the coaxiality between the screw and the guide sleeve, so that the coaxiality between the screw and the guide sleeve is high, and the structure Simple and easy to use. Compared with Embodiment 1, since only one through hole needs to be provided on the side wall of the cavity, the strength of the fixed pliers bod...

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that the self-adaptive adjustment device includes two elastic parts and two adjustment screws, the outer section of the guide sleeve is square, and the adjustment screws are embedded in the cavity In the through hole of the side wall, one end of the elastic member abuts or is screwed to the front end of the adjustment screw, and the other end abuts against the outside of the guide sleeve, and the two elastic members are respectively connected to the guide sleeve Two adjacent side surfaces on the outside are in contact, and the centerlines of the two adjusting screws are on the same plane. The elastic component is a spring or a shrapnel. The elastic part is a spring or a shrapnel. Other structures and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0050] In this embodiment, the coaxiality between the lead screw and the guide sleeve is adjusted by setting tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com