Cutting tool for fireproof and flame resistant materials

A fire-resistant, flame-retardant, cutting tool technology, applied in metal processing, etc., to achieve the effects of shortening the working cycle, improving the reliability of power supply, and shortening the power outage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

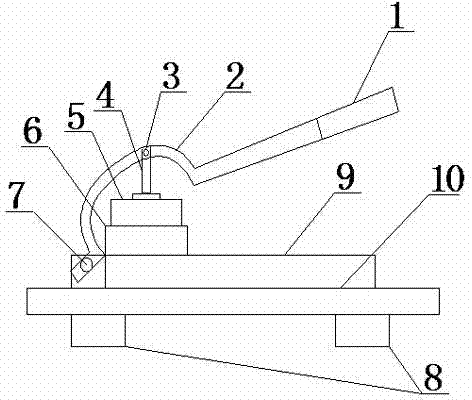

[0012] Embodiment 1, a fire-resistant flame-retardant material cutting tool, its structure is: the middle part of the handle (1) is provided with a bending part (2), and the front end of the bending part (2) and the stage (9) pass through the pin shaft ( 7) Flexible connection, the stage (9) is fixed on the base (10), the bottom of the base (10) is fixed with outriggers (8), and the bending part (2) is connected with the connecting rod ( 4) Flexible connection, the end of the connecting rod (4) is fixedly connected with a model cutter (5), and a fire-resistant material (6) is placed on the stage (9) directly below the model cutter (5).

[0013] The present invention is used in this way: the fire-resistant and flame-retardant material (6) is placed on the stage (9) directly below the model cutter (5), and the required fire-resistant and flame-retardant material model can be cut out by pressing down on the handle (1) , the size and shape of the model cutter (5) can be changed as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com