Spherical bogie

A bogie and ball-type technology, applied in the field of bogies, can solve problems such as roadway blockage, shuttle wheel derailment, center of gravity deviation, etc., to prevent derailment, solve friction problems, and facilitate disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in combination with specific implementations according to the accompanying drawings.

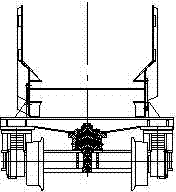

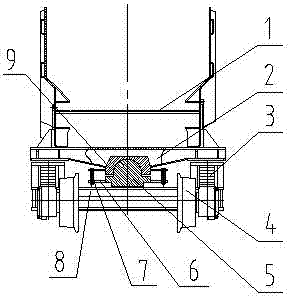

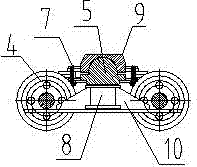

[0013] Such as image 3 , Figure 4 As shown, the spherical bogie is located at the lower part of the car body 1 of the rail-wheel type shuttle mine car, and it includes a wheel set 4, a symmetrically arranged side beam 10 connected to the wheel set, and generally passes through a guide between the side beam and the wheel set. Frames (not shown in the figure) are connected, a spring assembly 3 is provided, a bolster 8 is arranged between the side beams, and the bolster is perpendicular to the side beams at both ends, and a crossbeam 2 is arranged on the car body 1, and the width of the crossbeam is two The end gradually increases toward the middle position, the beam is provided with a spherical concave groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com