Push type automatic packaging bag opening shaping machine

An automatic packaging and shaping machine technology, applied in packaging and other directions, can solve problems such as bag opening shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

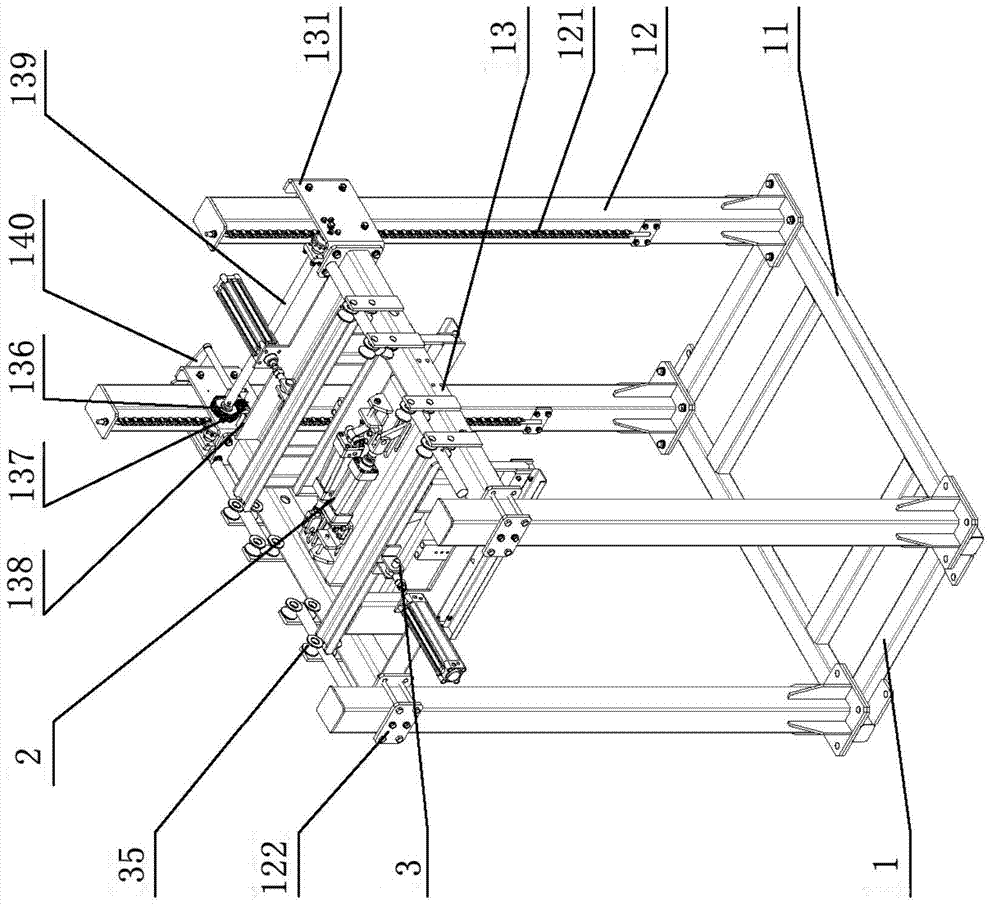

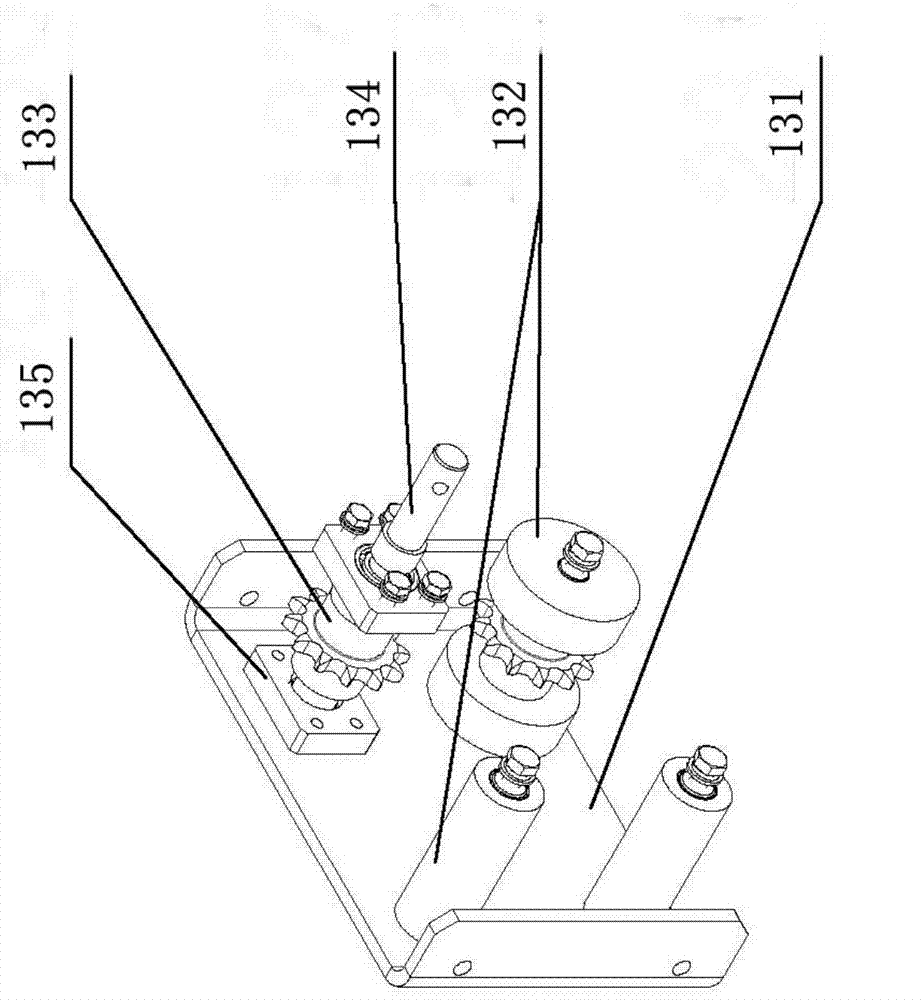

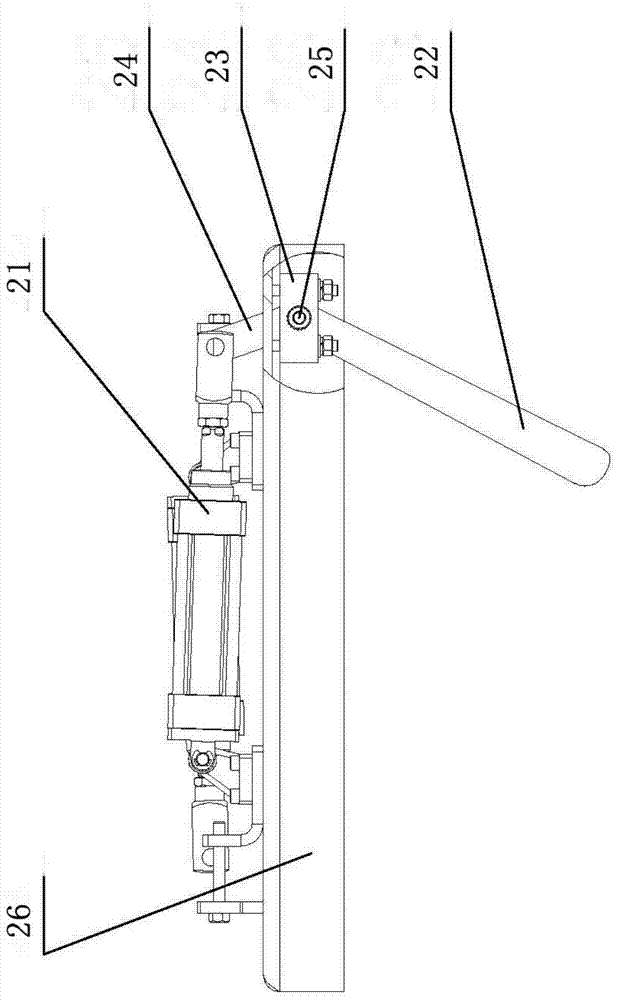

[0044] See figure 1 , figure 2 , image 3 and Figure 4 As shown, figure 1 It is a schematic structural diagram of a first preferred embodiment of a push-type automatic packaging bag mouth shaping machine of the present invention. figure 2 It is a partial structural diagram of the return sleeve of the first preferred embodiment of the push-type automatic packaging bag mouth shaping machine of the present invention. image 3 It is a schematic diagram of the structure of the bag shifting device of the first preferred embodiment of the push-type automatic packaging bag mouth shaping machine of the present invention. Figure 4 It is a partial structural diagram of the bag pressing device of the first preferred embodiment of the push-type automatic packaging bag mouth shaping machine of the present invention. The push-type automatic packaging bag mouth shaping machine of the present invention is mainly composed of a frame 1, a bag removing device 2 and a bag pressing device 3. Among...

Embodiment 2

[0053] See Figure 5 As shown, Figure 5 It is a schematic structural view of a second preferred embodiment of a push-type automatic packaging bag mouth shaping machine of the present invention. This embodiment is basically the same as the first embodiment. The only difference is that: in order to realize that the opening of the packaging bag is torn flat after the opening of the bag plate 22, the opening of the packaging bag is parallel to the horizontal plane when the bag plate 22 is folded. To avoid the unevenness of the two ends of the bag mouth from affecting the sealing effect, the bag shifting device 2 of the push-type automatic bag mouth shaping machine of the present invention is provided with a lifting mechanism 27. The lifting mechanism 27 is mainly composed of a lifting cylinder 271, a lifting guide rod 272 and a limit guide wheel 273. The lifting cylinder 271 is mounted on the horizontal suspension 13 by a flange, and the piston rod of the lifting cylinder 271 is co...

Embodiment 3

[0057] See Image 6 and Figure 7 As shown, Image 6 It is a schematic structural diagram of a third preferred embodiment of a push-type automatic packaging bag mouth shaping machine of the present invention. Figure 7 It is a schematic diagram of the structure of the bag shifting device of the third preferred embodiment of the push-type automatic packaging bag mouth shaping machine of the present invention. This embodiment is basically the same as the second embodiment. The only difference is that the bag shifting device 2 is mainly composed of a bag shifting cylinder 21 and a bag shifting plate 22. The bag shifting cylinder 21 is installed on the "U"-shaped seat plate 26, A hole is opened at one end of the bag plate 22, and the piston rod of the bag shifting cylinder 21 is inserted into the hole and fixed with a nut. The bag shifting plate 22 is perpendicular to the piston rod of the bag shifting cylinder 21. The movement mode of the bag shifting end of the bag shifting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com