Magnetic levitation automatic constant yarn leading tension roving serial suspension spindle

A technology of magnetic levitation and hanging spindle, which is applied to spinning machines, continuous winding spinning machines, textiles and paper making, etc., can solve the problems of increasing the operator's operating intensity, affecting the spinning quality, and the yarn sliver falling easily. Easy to promote, less cost increase, and the effect of preventing broken ends and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

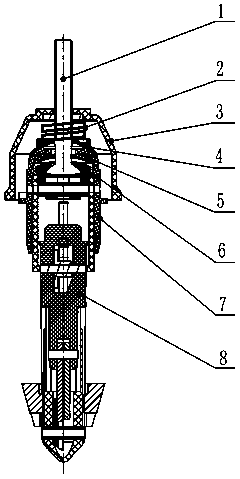

[0014] The following embodiments further illustrate the technical solutions of the present invention in conjunction with the accompanying drawings.

[0015] This embodiment is applicable to the situation of low yarn drawing tension. The boom bolt 1 is fixed to the spinning frame hanger frame through the upper nut, the boom bolt 1 is fixed to the hanger cap 3 through the nut in the middle of the screw rod, and a high-Gauss magnet (magnet) with SN polarity is set at the tail of the boom bolt 1 The piece 5 and the bearing piece 6 are fitted with a damping ring 4 that slides against the inner sleeve 7 of the hanging spindle, and a damping spring 2 is set between the outside of the top of the damping ring 4 and the inside of the top of the hanging spindle cap 3, and the main body of the hanging spindle 8 is mounted Roving for spinning. All plastic parts are made of polyoxymethylene.

[0016] For cotton roving: The magnetic repulsion force controls the weight of the roving: 4kg~30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com