Motorcycle engine crankcase and engine

A crankcase and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of fast oil return speed, reduced engine reliability, and high heat load of the whole machine, so as to improve the performance of the whole machine and improve cooling Effect, optimize the effect of oil inlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

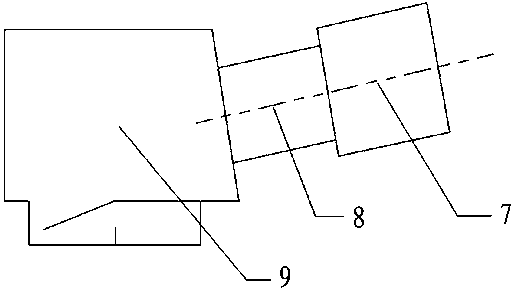

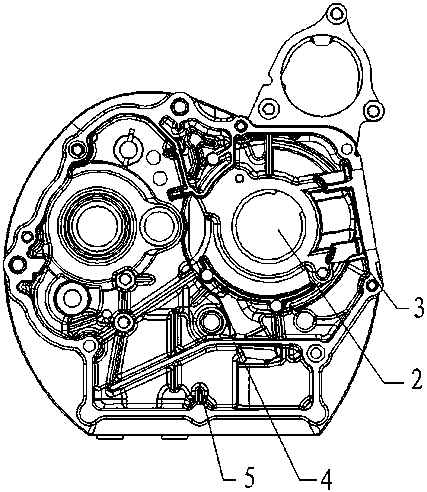

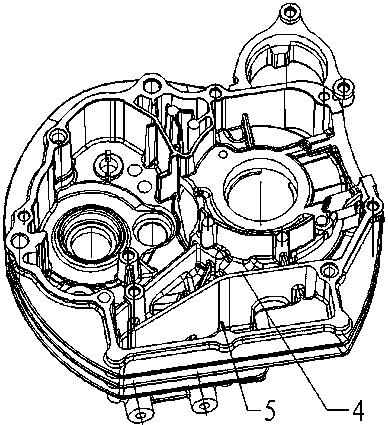

[0022] see Figure 1 to Figure 5 , a motorcycle engine crankcase, with a crankcase body 9, the crankcase body 9 is composed of left and right crankcase bodies 2, 1, and the inner wall of the crankcase body is provided with a lubricating oil return port 3 near the cylinder side, embodiment Among them, the lubricating oil return port 3 is arranged on the left crankcase body, and the lubricating oil pump oil inlet is arranged at the bottom of the crankcase body 9 close to the cylinder body 8. In the embodiment, the lubricating oil pump oil inlet 6 is arranged on the right crankcase body 1 The bottom is close to the side of the cylinder block 8, and the crankcase body 9 is located below the lubricating oil return port 3. The box body reinforcement cross rib 4 is arranged, and the box body reinforcement cross bar 4 divides the interior of the crankcase body 9 into an upper space and a lower space, and the box body The reinforced transverse rib 4 is away from the lubricating oil ret...

Embodiment 2

[0029] An engine is provided with the crankcase of the motorcycle engine in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com