Pin type anti-explosion door used for industrial boiler

A technology for industrial boilers and explosion-proof doors, used in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of poor sealing performance of spring-type explosion-proof doors under conditions of use, and achieve good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

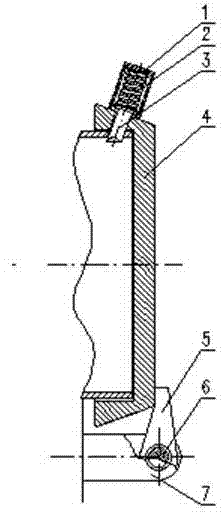

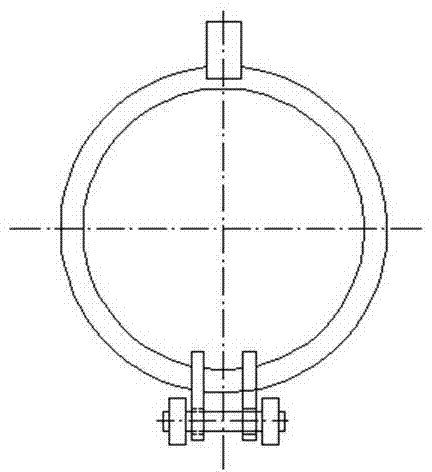

[0021] 1. A pin-type explosion-proof door for industrial boilers, comprising: spring cover 1, spring 2, opening pin 3, explosion-proof door main body 4, movable hinge 5, hinge shaft 6, fixed hinge 7, is characterized in that: fixed hinge 7 and The inner cavity of the boiler is fixedly connected, the movable hinge 5 is fixedly connected with the explosion-proof door main body 4, and the fixed hinge 7 is movably connected with the movable hinge 5 through the hinge shaft 6, so that the explosion-proof door main body 4 can make an angle of 180° with the clockwise hinge axis as the axis The rotation of the spring cover 1 is installed on the main body 4 of the explosion-proof door at an angle of 180° from the hinge axis. There is a built-in spring 2 and an opening pin 3. One end of the opening pin 3 is in contact with the spring 2, and the other end passes through the inner cavity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com