Assembly for tightening and securing male and female parts fitted together

A technology for fixing components and parts, applied in the attachment of toolholders, passing elements, pipes/fittings/fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

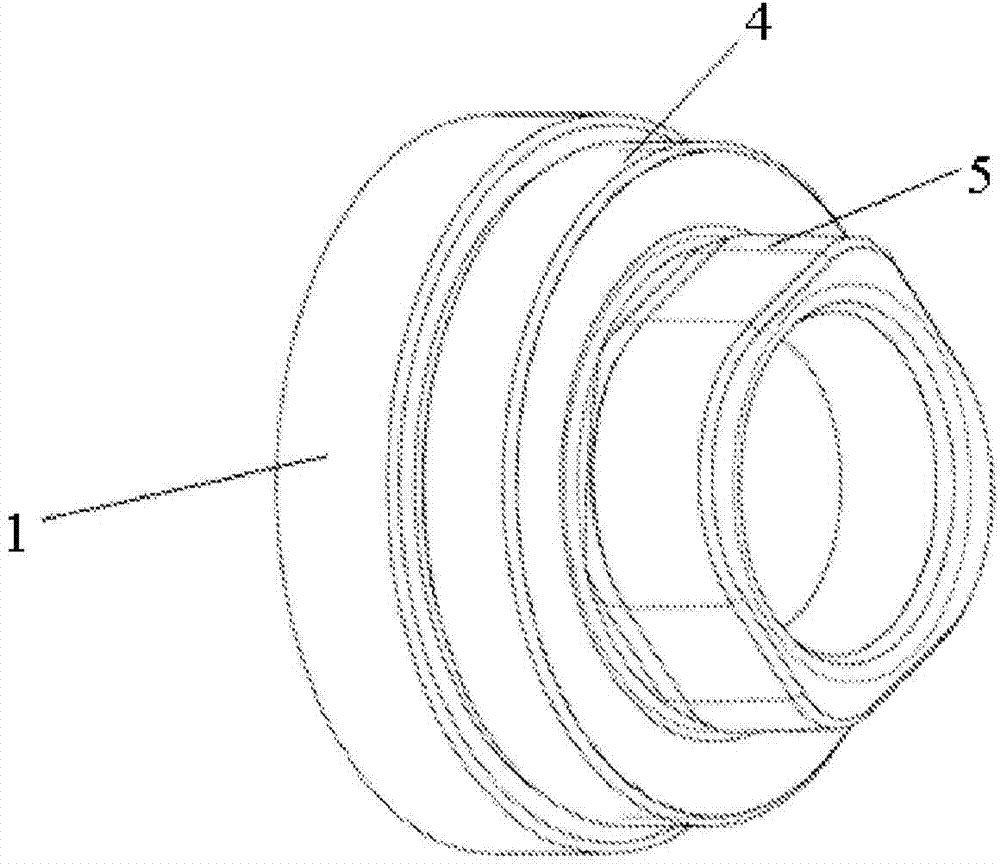

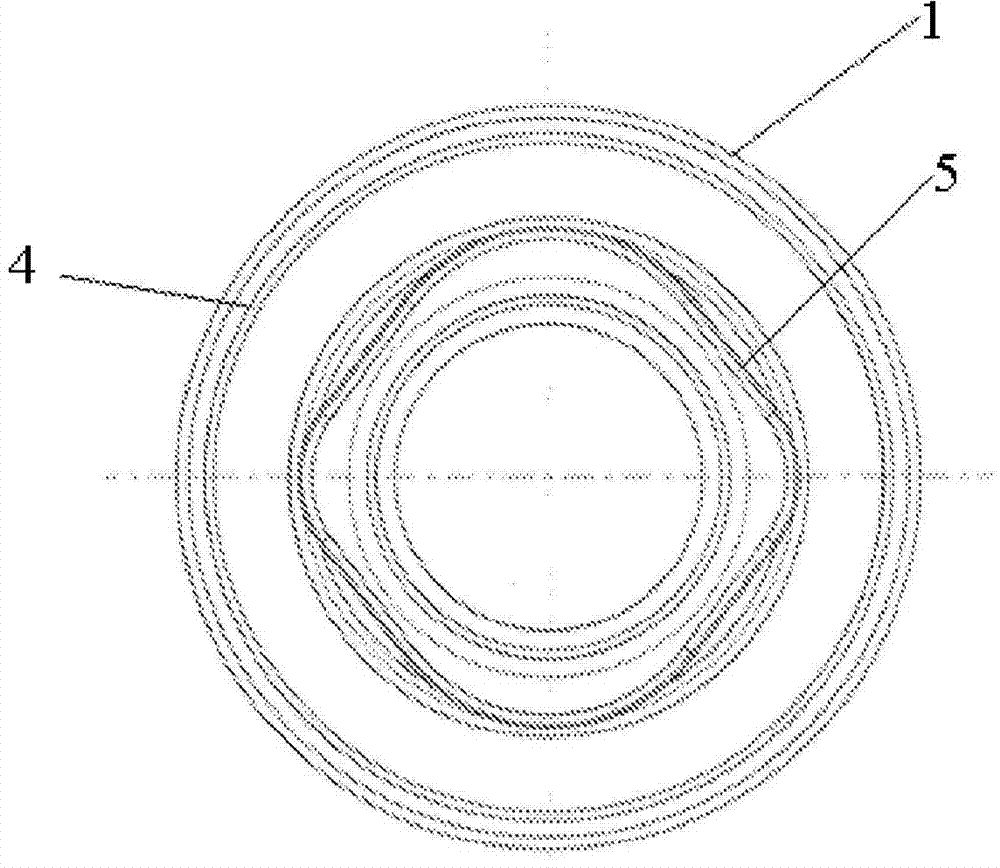

[0036] According to a first embodiment of the assembly of the invention, the ring device 3 is mounted fixed in translation to the female part 2 .

[0037] According to a second embodiment of the assembly of the invention, the annular device 3 is mounted fixed in translation to the male part 1 .

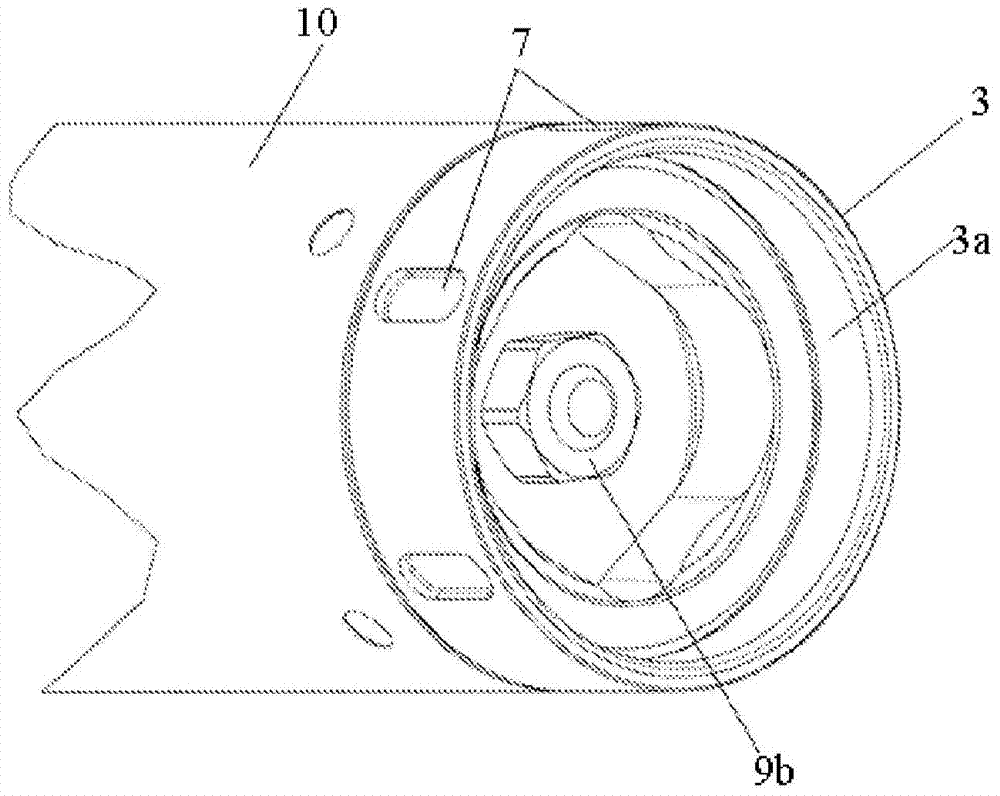

[0038] According to a particular feature, at least one of these parts, namely the male part 1 or the female part 2 , is mounted on a support structure 10 . Said support structure 10 may be formed by an axial structure comprising at least one hollow part forming a tubular duct. The assembly may also be formed by a fit and / or threaded / threaded interaction between a portion of the inner surface of the tubular part of the support structure 10 and the peripheral surface of the male part 1 or female part 2 .

[0039] Likewise, the fitting of either the male part 1 or the female part 2 into the support structure 10 may involve a shoulder on the mating part adjoining the end of the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com