Assemblies for fastening and securing male and female parts that fit together

A technology for fixing components and parts, used in the attachment of toolholders, passing elements, pipes/fittings/fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

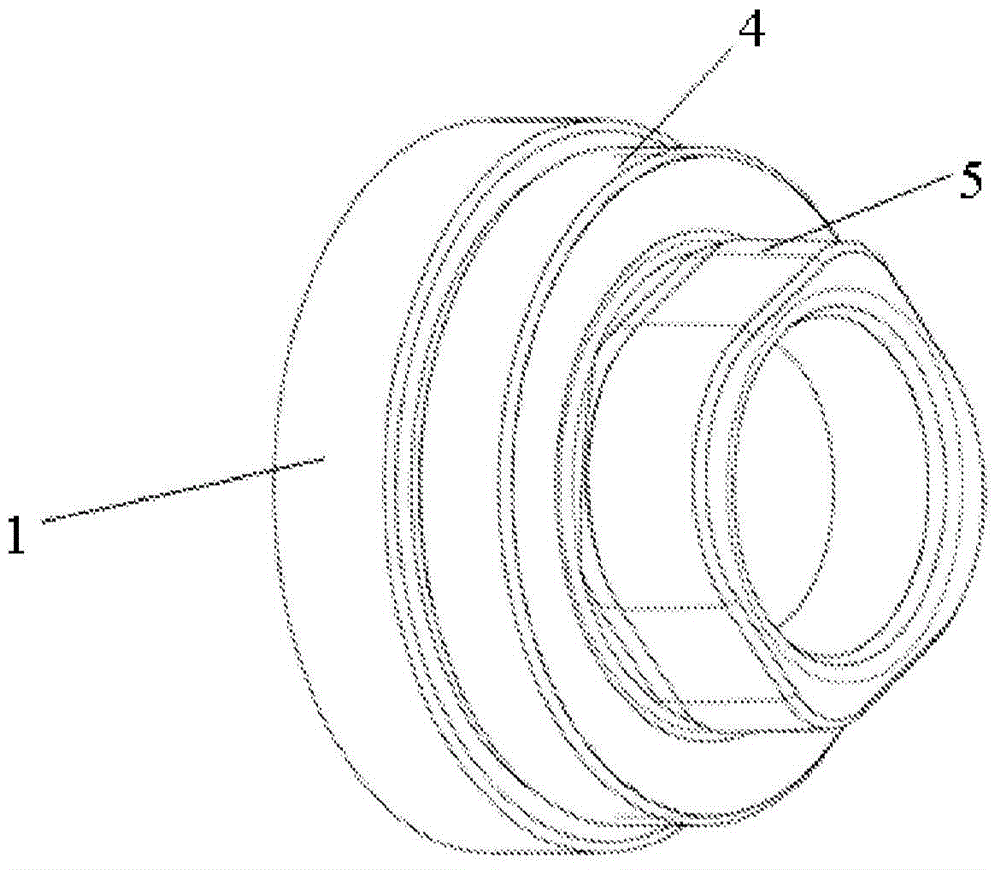

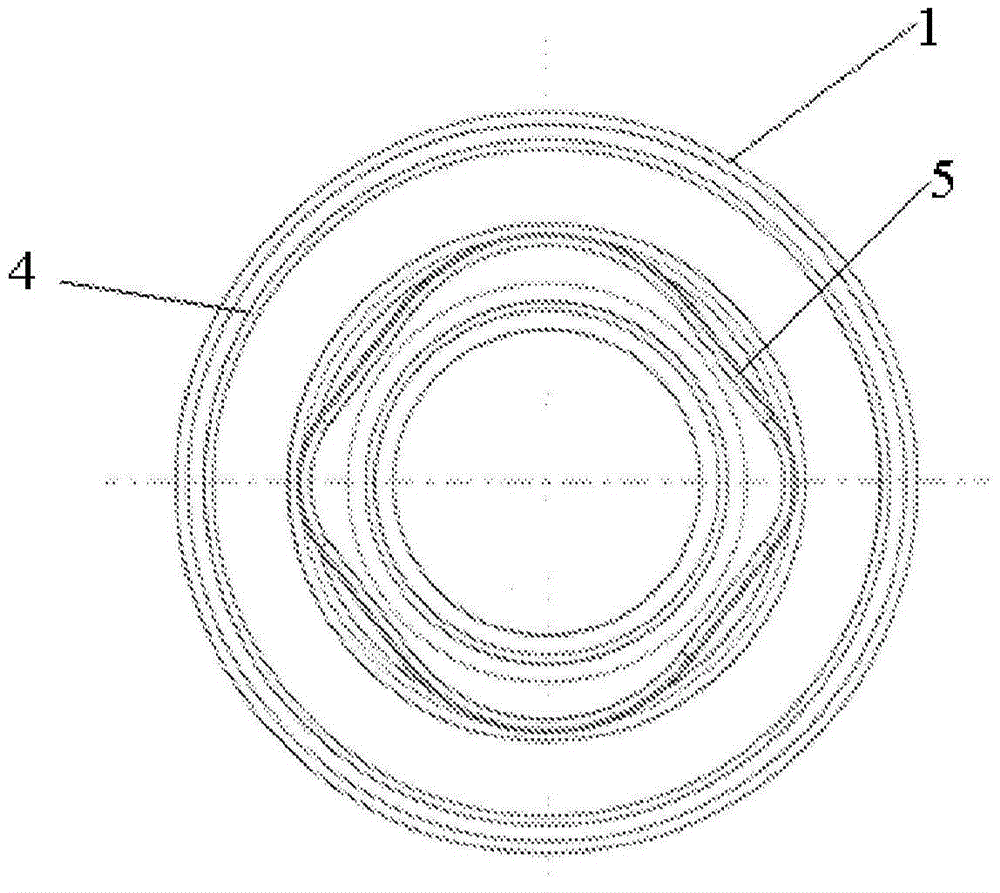

[0036] According to the first embodiment of the assembly of the present invention, the ring device 3 is mounted to be fixed to the female part 2 in a translational manner.

[0037] According to the second embodiment of the assembly of the present invention, the ring device 3 is installed to be fixed to the male part 1 in a translational manner.

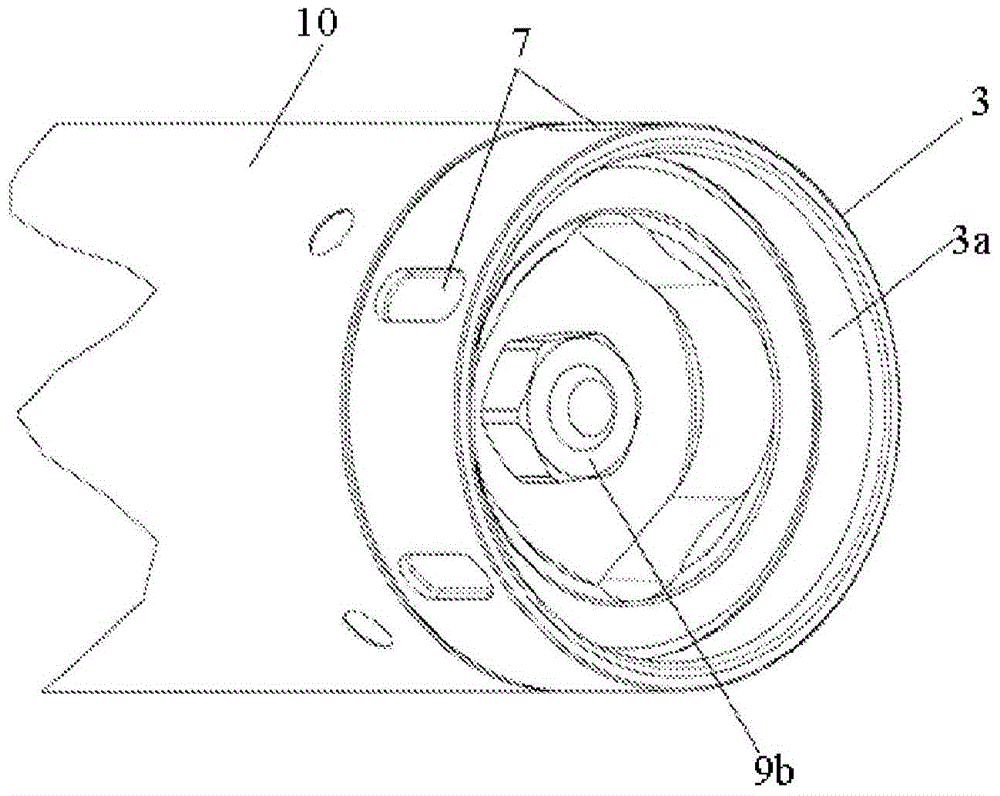

[0038] According to a specific feature, at least one of these components (ie, the male part 1 or the female part 2) is mounted on the support structure 10. The support structure 10 may be formed by an axial structure including at least one hollow part forming a tubular pipe. The assembly can also be formed by the fit and / or tapping / threading interaction between a part of the inner surface of the tubular part of the support structure 10 and the peripheral surface of the male part 1 or the female part 2 .

[0039] Similarly, the mating of the male part 1 or the female part 2 into the support structure 10 may involve a shoulder on a mating pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com