Prosthesis system with a liner and a prosthesis socket

A technology of prosthetics and bushings, applied in the field of prosthetic systems, to achieve the effect of preventing rotational movement and translational movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

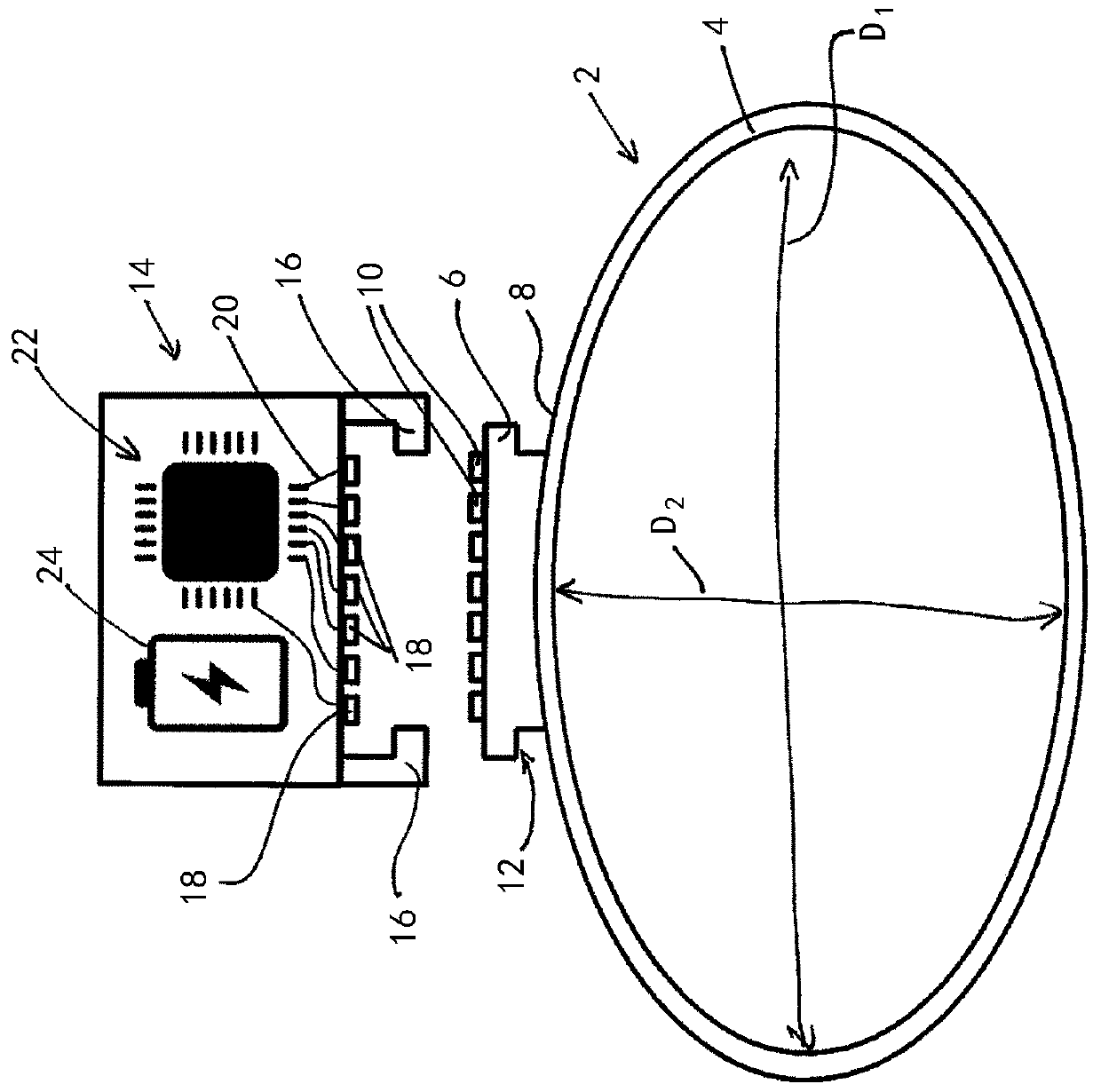

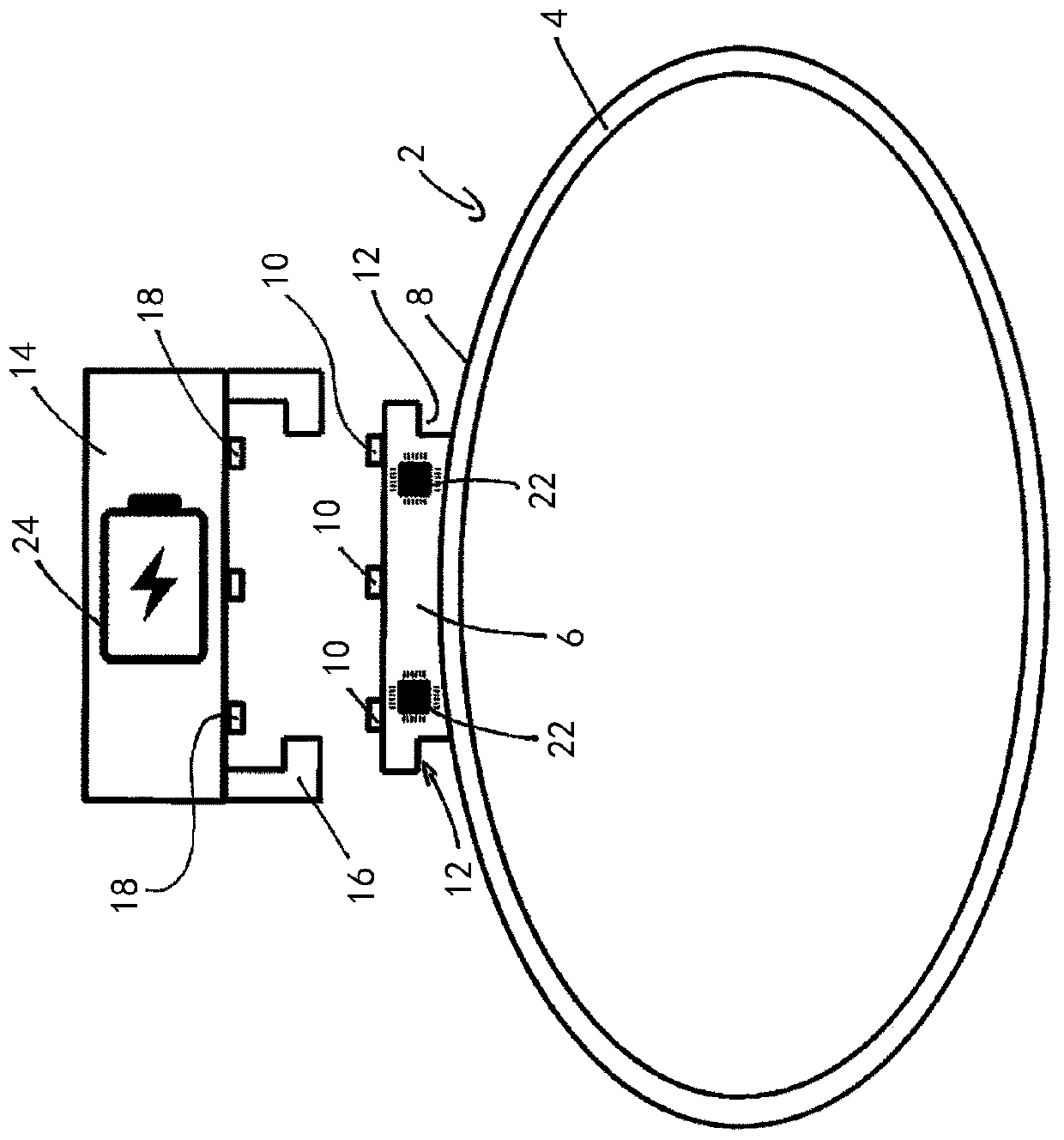

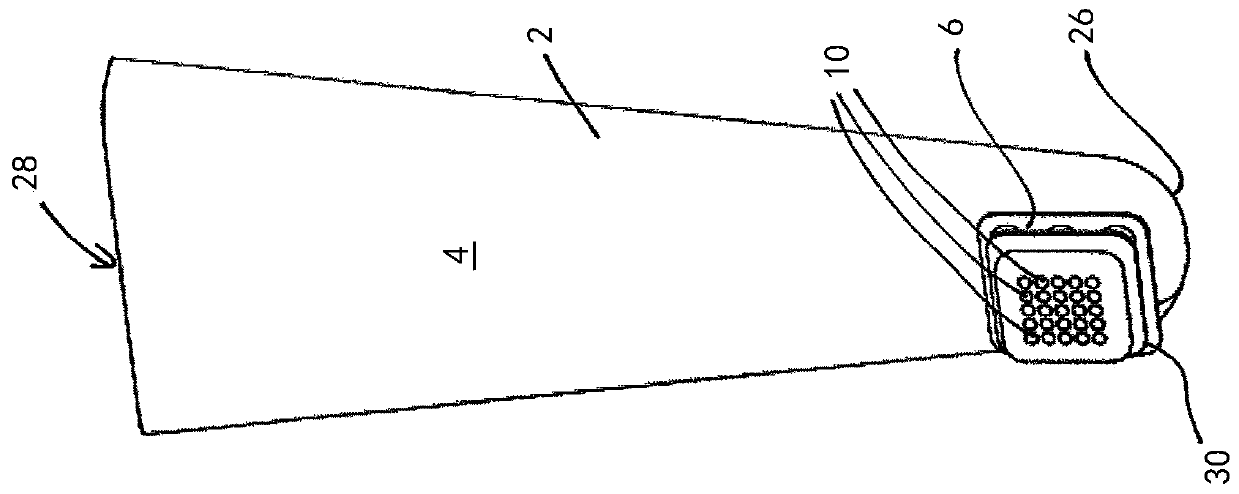

[0026] figure 1 The bushing 2 is shown in section. The shell surface 4 is shown in cross section. Instead of having a circular cross-section, the bushing has a first diameter D 1 and a second diameter D perpendicular to the first diameter 2 , the second diameter is smaller than the first diameter D 1 . The first connecting device 6 is at the second diameter D 2 It is arranged on the outer side 8 of the bushing 2 in the extension of the bushing 2 . The connecting device has an electrical contact 10 and two projections 12 via which electrical contact and mechanical locking can be achieved.

[0027] A part of the prosthesis cartridge that is not shown is the second connection device 14 , which has two hook elements 16 that interact with the projections 12 of the first connection device 6 . If the hook 16 engages with the projection 12 , the electrical contact 18 of the second connecting device bears against the electrical contact 10 of the first connecting device 8 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com