Clamp for clamping box body type workpiece

A technology for workpieces and boxes, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve problems such as poor rigidity and difficult clamping, and achieve high positioning accuracy and firm and reliable clamping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

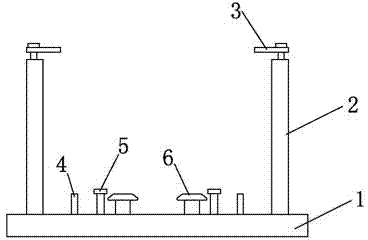

[0014] see figure 1 , a preferred embodiment of the present invention provides a clamping fixture for box-type workpieces, comprising: a square bottom plate 1, four corners of the bottom plate 1 are respectively provided with support columns 2, and the top ends of the support columns 2 A pressing plate 3 is provided, a plurality of positioning pins 4 and adjusting bolts 5 are provided on the base plate 1 , and two elastic positioning pins 6 are provided in the middle of the base plate 1 . During use, the workpiece is laid flat on the height-adjustable locating pin 4 to form a plane, and the two elastic locating pins 6 on the base plate 1 cooperate with the assembly holes on the workpiece. At the same time, check whether the left and right centerlines of the workpiece are on the same level. If not, use the adjustment bolt 5 to fine-tune the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com