Copper foil press fit stripping mechanism with release paper

A stripping mechanism and take-off technology, applied in lamination, lamination device, lamination auxiliary operation, etc., can solve the problems of slow efficiency and high cost, achieve labor saving, expand sharing, save manufacturing costs and management costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

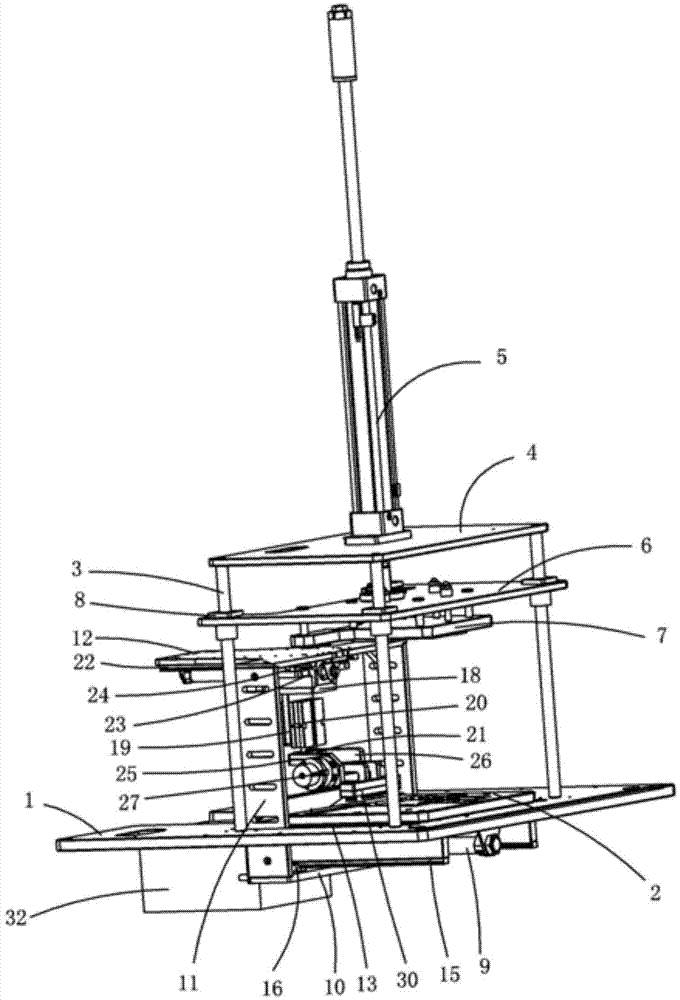

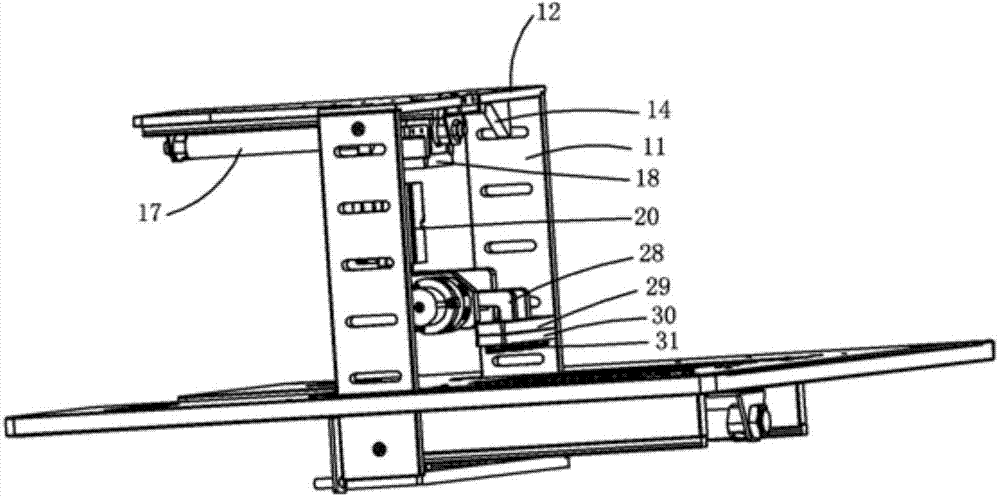

[0022] Examples, see attached figure 1 and 2 , a copper foil pressing and peeling mechanism with a release paper, which includes a base plate 1, a carrier 2 is installed on the base plate, a PCB board is placed in the carrier, and a copper foil with a release paper is placed on the PCB board; The lifting cylinder fixed plate 4 is installed on the said base plate through the pillar 3, and the lifting cylinder 5 is installed on the top of the lifting cylinder fixed plate; There are four pillars, the lower ends of the four pillars are fixed on the base plate, the upper ends are fixed on the cylinder mounting plate, and the four pillars pass through the lifting plate respectively, and four guide sleeves 8 are installed on the lifting plate. The pillars pass through the corresponding guide sleeves respectively. The guide pillars and the guide sleeves have a guiding effect. When the lifting cylinder drives the lifting plate to move up and down, the lifting plate can move up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com