Batched medicine bottle plug adding equipment

A medicine bottle and equipment technology, applied in the field of medicine bottle batch stoppering equipment, can solve the problems of low production efficiency and high cost of machinery and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

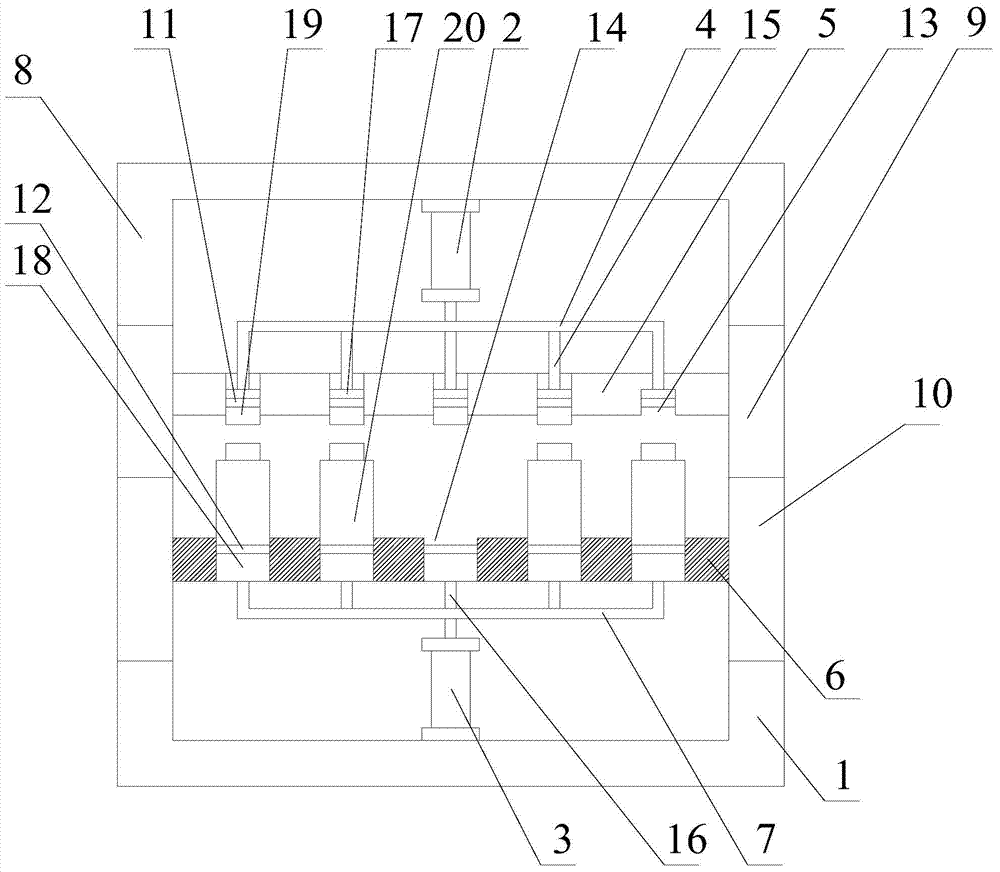

[0016] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a batch stoppering equipment for medicine bottles proposed by the present invention.

[0017] see figure 1 , the present invention proposes a batch stoppering equipment for medicine bottles proposed by the present invention, comprising:

[0018] Base 1, first power unit 2, second power unit 3, first plate 4, second plate 5, third plate 6, fourth plate 7, first bracket 8, second bracket 9, third bracket 10 , the first movable block 11, the second movable block 12;

[0019] The first bracket 8, the second bracket 9, and the third bracket 10 are installed on the base 1, the first power unit 2 is installed on the first bracket 8, and the first flat plate fixed on the front end of the piston rod of the first power unit 2 4. The second flat plate 5 movably installed on the second bracket 9, the third flat plate 6 movably installed on the third bracket 10, and the third flat plate 6 fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com