A kind of preparation method of textured non-slip glove fabric

A fabric and anti-skid technology, applied in the field of textile materials, can solve the problems of complex preparation method of anti-skid gloves, low market share and high friction resistance, and achieve the effects of being beneficial to market promotion, low production cost and strong grip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

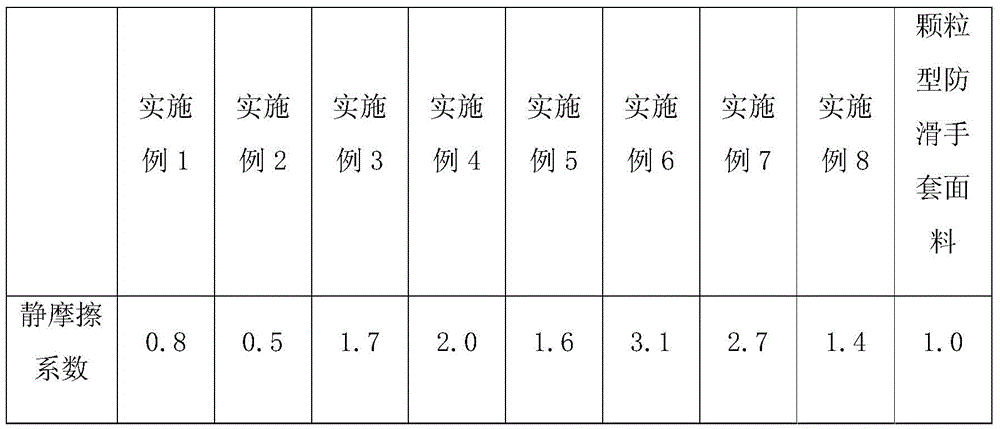

Embodiment 1

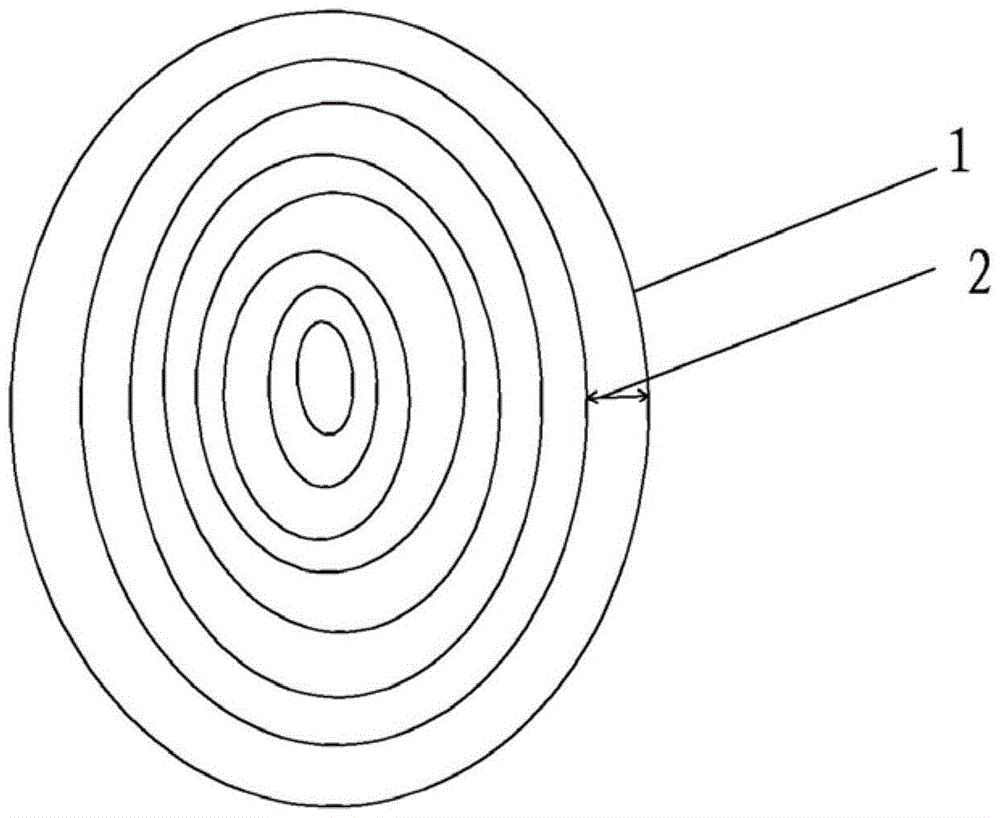

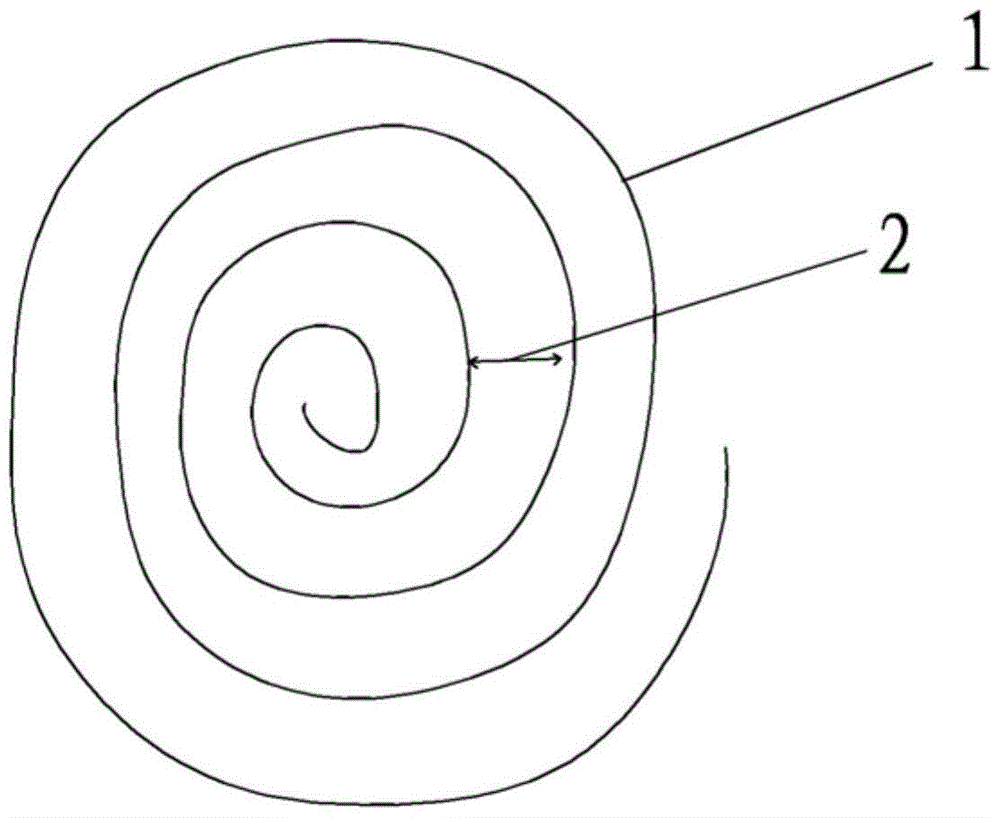

[0031] (1) Randomly distribute thread shapes with a diameter of 0.5cm in the hollowed out mold. The hollowed out part in the mold is threaded, and the area of the figure reaches 95% of the total area of the mold. The width of the lines in the hollowed out part is 1mm. The spacing is 3mm.

[0032] (2) Place the hollow mold on an improved flat screen printing machine, add nitrile latex with a viscosity PVI value of 1.3 on the upper surface of the hollow mold, then place the fabric under the hollow mold, and move the scraper at a speed of 23m / min , so that the nitrile latex falls on the surface of the fabric through the hollowed out position to obtain a coated fabric.

[0033] (3) The coated fabric was immersed in a coagulant for 50 seconds to solidify the nitrile latex on the surface of the fabric, then washed with water, and dried at 45° C. to obtain a textured non-slip glove fabric with a coating thickness of 0.1 cm.

Embodiment 2

[0035] (1) Randomly distribute ellipses with a diameter of 0.5-3cm in the hollowed out mold. The hollowed out part in the mold is elliptical, and the area of the figure reaches 5% of the total area of the mold. The width of the lines in the hollowed out part is 2mm. The spacing between the ellipses is 4mm.

[0036] (2) Place the hollow mold on an improved flat screen printing machine, add nitrile latex with a viscosity PVI value of 1.3 on the upper surface of the hollow mold, then place the fabric under the hollow mold, and move the scraper at a speed of 23m / min , so that the nitrile latex falls on the surface of the fabric through the hollowed out position to obtain a coated fabric.

[0037] (3) The coated fabric was immersed in a coagulant for 60 seconds to solidify the nitrile latex on the surface of the fabric, then washed with water, and dried at 60° C. to obtain a textured non-slip glove fabric with a coating thickness of 0.3 cm.

Embodiment 3

[0039] (1) Randomly distribute thread shapes with a diameter of 1.0cm in the hollowed out mold. The hollowed out part in the mold is threaded. The area of the figure reaches 50% of the total area of the mold. The width of the lines in the hollowed out part is 1.5mm. The pitch is 3.8mm.

[0040] (2) Place the hollow mold on an improved flat screen printing machine, add nitrile latex with a viscosity PVI value of 1.4 on the upper surface of the hollow mold, then place the fabric under the hollow mold, and move the scraper at a speed of 25m / min , so that the nitrile latex falls on the surface of the fabric through the hollowed out position to obtain a coated fabric.

[0041] (3) Immerse the coated fabric in a coagulant for 55 seconds to solidify the nitrile latex on the surface of the fabric, then wash it with water, and dry it at 50° C. to obtain a textured non-slip glove fabric with a coating thickness of 0.5 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com