A pressure automatic compensation type pressure difference injection particle continuous injection device

A technology of automatic compensation and pressure compensation, applied in drilling equipment, drilling equipment and methods, earthwork drilling, etc., can solve the problems of wear, restricting the commercialization process of particle impact drilling technology, poor sealing performance of screw extruders, etc. Improve work efficiency, good anti-blocking effect, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

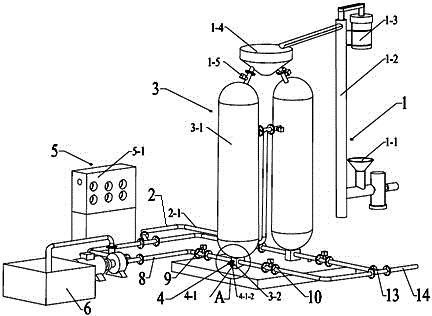

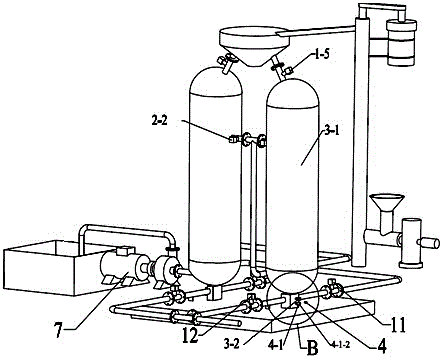

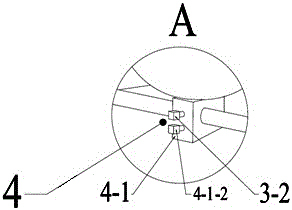

[0038] combined with Figure 1-13 , to further describe the present invention:

[0039] A pressure automatic compensating type differential pressure injection particle continuous injection device, including a particle lifting filling system (1), a pressure compensation system (2), a double-tank injection system (3), an anti-blocking mixing system (4) and a circuit The control system (5), the particle lift filling system (1) is connected to the inlet of the double-tank injection system (3), and the side wall of the double-tank injection system (3) is connected to the pressure compensation system (2). The bottom of the system (3) is connected to the anti-blocking mixing system (4), and the circuit control system (5) is installed on one side; the particle lifting filling system (1) lifts the particles to the double tank injection system (3) middle; the pressure compensation system can pre-boost the particle injection tank (3-1) of the double-tank injection system (3) to the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com