A Supporting Roller Mechanism that Can Be Replaced Quickly in a Long Distance

A technology that supports rollers and long distances, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of long-distance maintenance, overhaul, and replacement difficulties, and achieve the effect of fast long-distance maintenance, reliable support, and realization of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

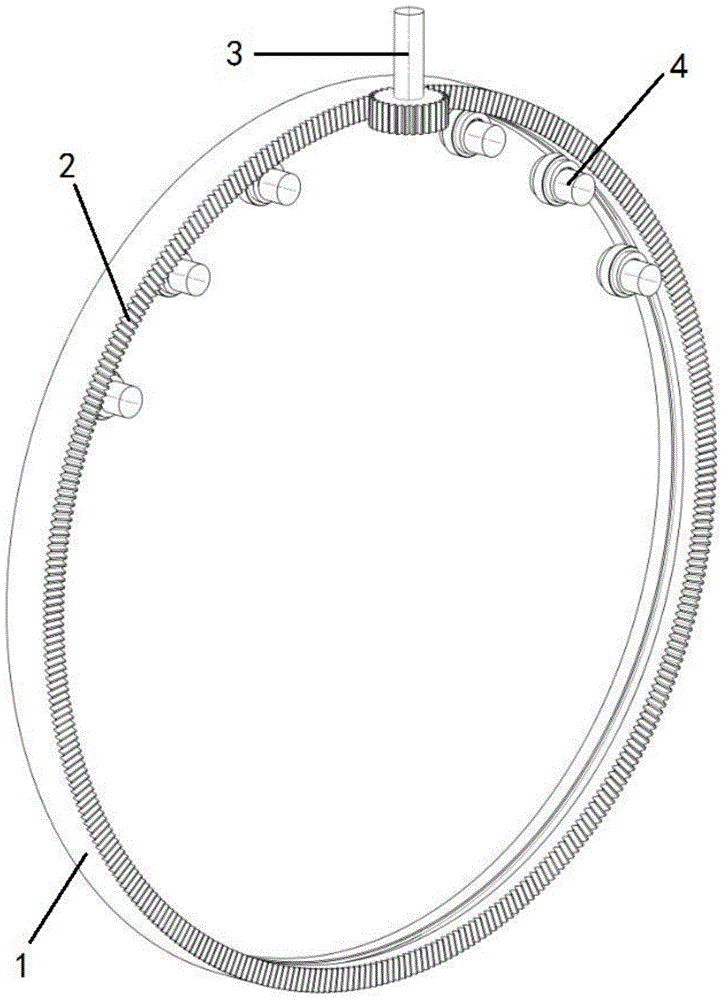

[0022] The supporting roller mechanism of the present invention is mainly aimed at a large-sized disc-shaped part similar to a waterwheel, which is immersed in a strong radioactive environment and rotates at a relatively low speed.

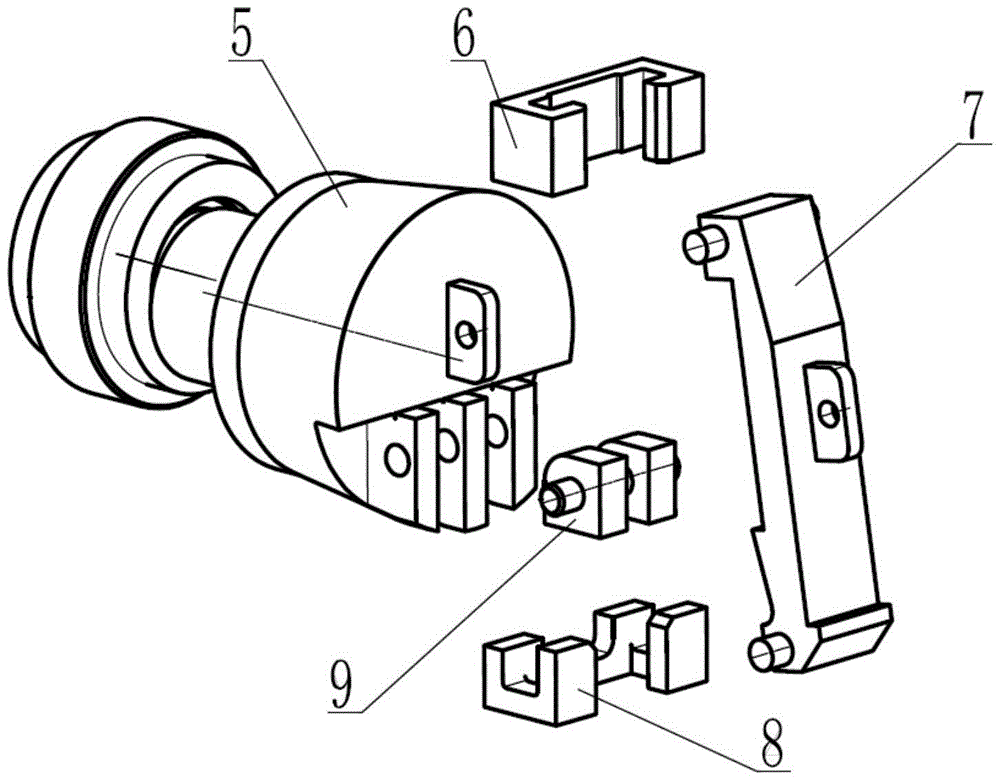

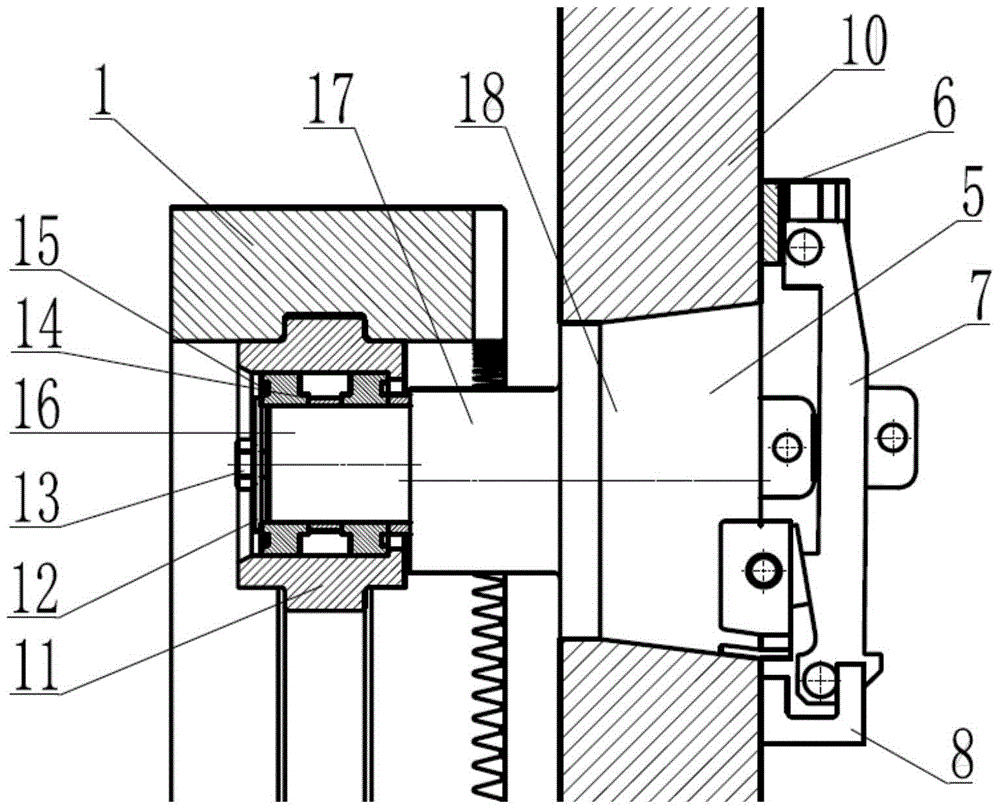

[0023] Such as figure 2 As shown, the supporting roller of the present invention is composed of a roller main body 5, an upper buckle 6, a lower buckle 8, a locking pin 7, a turning block 9 and a roller 11. The main body of the roller is divided into three sections, the front end is a cylindrical stick front end 16, the middle is a cylindrical stick middle part 17, and the tail end is a conical stick tail end 18. Roller main body front end is used for installing the roller 11 that can rotate flexibly, as image 3 As shown, the roller is fixedly installed on the front end of the roller main body 5 through a bearing 15 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com