Lamp special for chemical engineering

A special lamp, chemical technology, applied in the field of lighting, can solve the problems of poor safety factor, weak light transmittance, easy to break, etc., to achieve the effect of enhancing the range and intensity of light, increasing luminous brightness, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

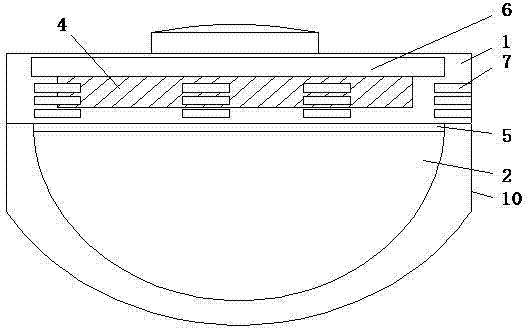

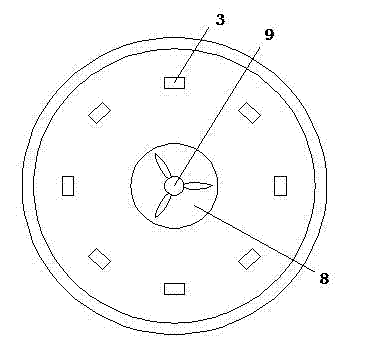

[0017] See figure 1 and figure 2 , the present invention has a lamp housing 1, a lamp shade 2, a light source 3 and a power supply 4; the lamp housing 1 is provided with a heat dissipation through hole 7; the lamp shade 2 is fastened with the lamp housing 1; The light source 3 is installed on the partition 5; the power supply 4 is installed and fixed on the circuit board 6 in the lamp housing 1, and is electrically connected to the light source 3; the light source 3 is a plurality of LED chips connected in parallel and in an annular array; Hole 8; a three-blade fan 9 is embedded in the through hole 8.

[0018] The surface of the lampshade 2 is covered with ridgeline lenses. The lampshade 2 is also covered with a grid type stainless steel protective cover 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com