Sand grain simulation ball with automatic timing function and simulation timing method

An automatic timing, sediment particle technology, applied in fluid dynamics test, machine/structural component testing, measuring device, etc., can solve the problems of heavy workload, difficult long-term research, large error, etc., to reduce test costs , the effect of preventing damage and reducing the initial timing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

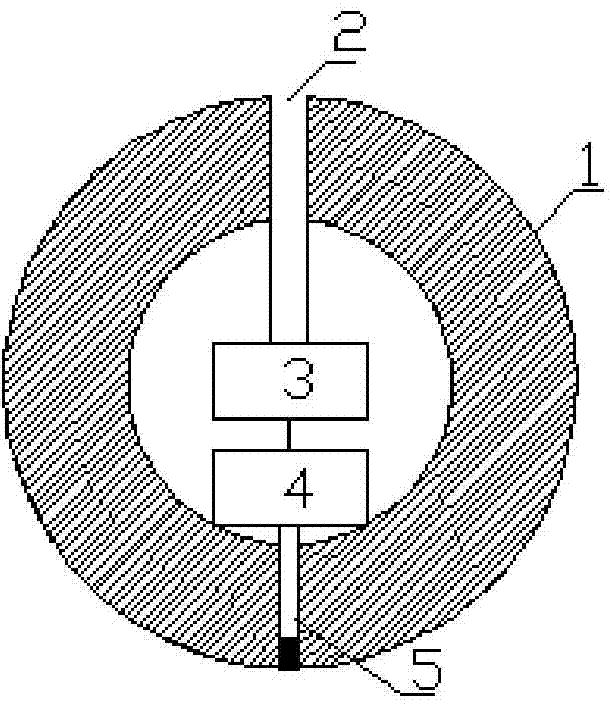

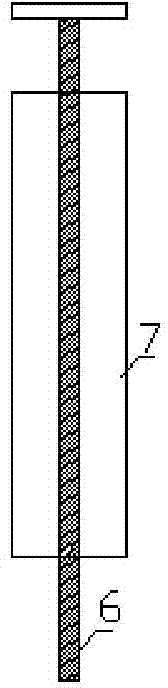

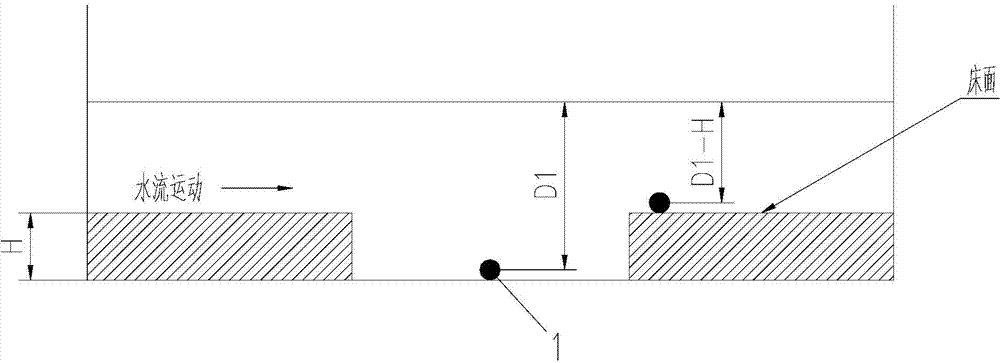

[0022] like figure 1 As shown in the figure, the sediment particle simulation ball with automatic timing function of the present invention includes an internal hollow simulation ball body 1, a water inlet pipe 2, a pressure sensor 3, a timer 4 and a data interface 5. The simulation ball body 1 is provided with The first hole and the second hole, the center of the first hole and the second hole is in a straight line with the center of the simulation ball body 1, the water inlet pipe 2 is installed in the first hole, and the end of the first hole away from the simulation ball body 1 is installed with a seal. The device, one end of the water inlet pipe 2 located in the main body 1 of the simulation ball is connected to the pressure sensor 3, the pressure sensor 3 is connected to the timer 4, the timer 4 is connected to the data interface 5, the data interface 5 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com